How to change UBL on a Bosch washing machine?

Anyone can cope with replacing UBL on a Bosch machine. You just need to understand the topic a little, pick up a hex screwdriver, remember safety precautions and not deviate from the relevant instructions. It remains to find out what algorithm we are talking about and how the blocker is diagnosed.

Anyone can cope with replacing UBL on a Bosch machine. You just need to understand the topic a little, pick up a hex screwdriver, remember safety precautions and not deviate from the relevant instructions. It remains to find out what algorithm we are talking about and how the blocker is diagnosed.

Repair algorithm

Replacing the UBL on a Bosch washing machine is not difficult if you prepare and anticipate possible difficulties. First of all, we take a flat-head screwdriver and a hex wrench, which will be useful for disconnecting the “blocker”. After we turn off the power to the washing machine, disconnect it from the sewer and water supply, turn the machine with the back panel towards you and begin work:

- remove the two bolts from the back that secure the washer cover;

- we push the cover from front to back, trying to lift it in order to unhook the panel from the plastic clips;

- tilt the body back so that the drum “moves away” from the front wall;

- put your hand into the vacant space between the body and the drum;

- with the other hand we hold the blocker from below;

- Using a flashlight and armed with a hexagon, we free the UBL from the retaining bolts and wiring;

- remove the locking device;

- installing a new blocker.

On Bosch washing machines, it is recommended to reach the blocker through the “top”.

The UBL can be removed faster through the lid, but there is a difficulty - you have to act almost “blindly”, by touch. If the “dark” option is not suitable, then you can try to get to the blocker through the hatch hole.It is necessary to remove the outer clamp from the cuff, tuck the freed edge of the elastic into the drum, and then remove the lock and locking device.

The difficulty of the second method is that you have to interact with the cuff. The sealing rubber is responsible for the tightness of the tank and, if displaced or incorrectly installed, will lead to leaks. But with careful handling and compliance with safety precautions, the risks are minimal.

Checking the blocking device

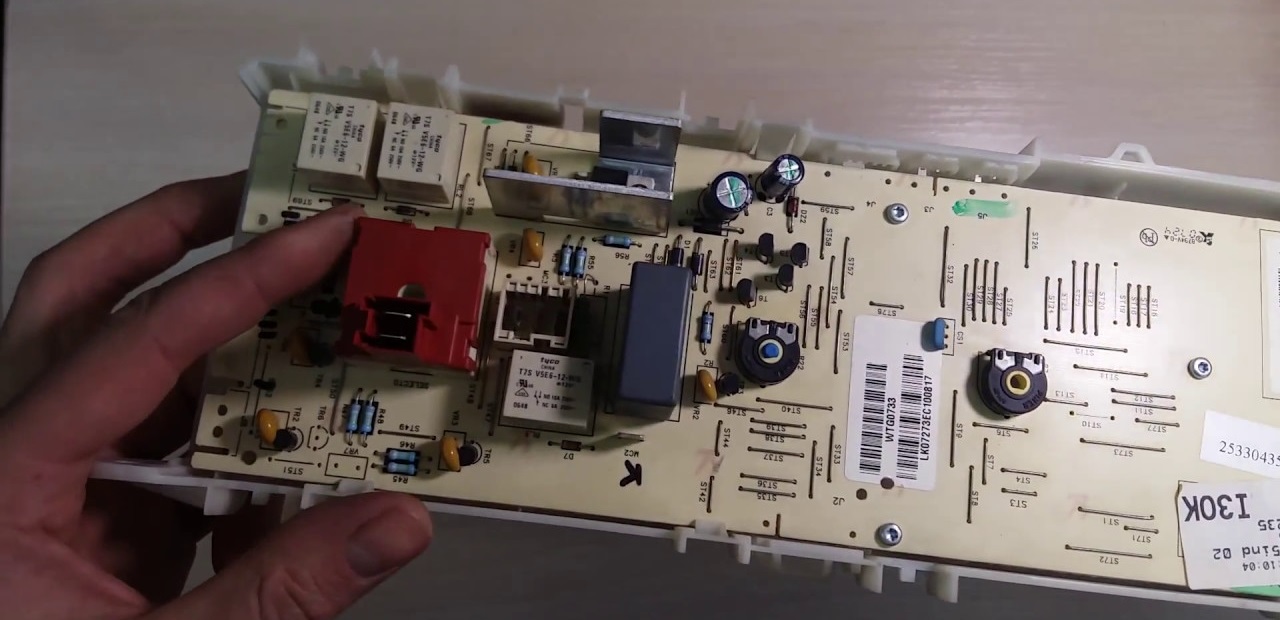

It is worth understanding that replacing the UBL is a last resort. Before purchasing a new blocker, it is recommended to check the functionality of the old one. It’s easy to do the diagnostics yourself:

- we study the electrical circuit of the UBL (must be given in the factory instructions);

- turn on the “Resistance” mode on the multimeter;

- apply the probes to the contacts of the blocker;

- evaluate the result (a working device will show a three-digit number);

- we test the UBL for a common contact (if “0” or “1” is displayed, it means the device is working).

Modern blockers are not repairable. It is much easier and cheaper to select an original analogue and replace the device. When choosing a UBL, you need to rely on the Bosch serial number. The cost of this part is low, but you will have to wait several days for the spare part, since the components are produced only in Germany.

Causes of the problem

Replacing the UBL is required when problems arise with closing the door. More precisely, the regular locking mechanism works, but there is no click from the electronic lock. In this situation, the washing machine cannot start. The control module does not receive information about the tightness of the drum, waits for a certain amount of time, and then signals a problem.The display shows the code “E03”, and if there is no screen on the washing machine, the corresponding display will begin.

Problems with the UBL are indicated by the error code “E03”.

UBL is responsible for the electronic locking of the hatch, which provides additional protection of the door from accidental opening during the cycle. Thanks to this measure, the user is protected from centrifugal force and possible flooding. But there is also a downside - if the device is faulty, the washing will not start. There are several reasons for the blocker to break down.

- Natural wear and tear. During operation, the bimetallic plates of the blocker are gradually erased, which inevitably leads to a breakdown in electrical conductivity. As a result, the blocker ceases to perform its functions and finally breaks down. The device cannot be repaired; replacement is indicated.

- Blockage. Perhaps the contacts are clogged, which affects electrical conductivity. The device needs to be disassembled and cleaned.

- Lost connection with the control board. The unit does not count the signal from the UBL if the “tracks” are burned out, module elements are damaged, or the firmware is faulty.

It is strongly not recommended to repair the electronic unit outside a service center!

Everyone is capable of diagnosing and replacing the blocker on their own. But if the cause of the malfunction is in the control board, then you need to contact a service center. We must not forget that the electronic module is a fragile and expensive spare part, requiring a special approach and special equipment. At home, the block can easily be damaged, even to the point of death.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment