How to replace the belt on a top-loading washing machine?

The principle of operation of “vertical” washing machines is the same as that of front-loading washing machines. The drum of washing machines equipped with a commutator motor is spun by a drive belt. If the rubber band breaks or falls off, the “home assistant” stops the cycle.

The principle of operation of “vertical” washing machines is the same as that of front-loading washing machines. The drum of washing machines equipped with a commutator motor is spun by a drive belt. If the rubber band breaks or falls off, the “home assistant” stops the cycle.

Let's figure out how to replace the belt on a top-loading washing machine with your own hands. We'll tell you how to choose the right components. We will explain what points you should pay attention to during the repair process.

We change the specified part

You can do the work of replacing the washing machine drive belt yourself, without calling a specialist. The process requires only a screwdriver. The main thing is to choose a drive belt suitable for a specific SMA model. The algorithm of actions will be slightly different from the repair of front-facing cameras, but in general the instructions are similar.

If the washing machine is still under warranty, it is better not to do it yourself, but to invite a service center specialist to replace the belt.

This is due to the fact that any self-repair will void the warranty. And if some more serious breakdown occurs in the future, then it will no longer be possible to claim free diagnostics and replacement of components.

If the warranty has expired, change the belt yourself. First of all, it is necessary to de-energize the SMA. Next, the machine is disconnected from the water supply and sewerage and moved to the center of the room so that it is convenient to work with it. Then:

- Unscrew the screws holding the side wall of the washing machine (this can be either the left or right panel; information on the location of the drive belt is in the equipment instructions);

- in some “verticals” the side wall is additionally secured with bolts located at the front - these also need to be removed;

- remove the side panel of the case and place it to the side;

- remove the deformed belt from the pulley (usually this is not required, since the elastic band breaks and lies underneath);

- purchase a new drive belt, focusing either on the model of the washing machine or on the markings of the old rubber band;

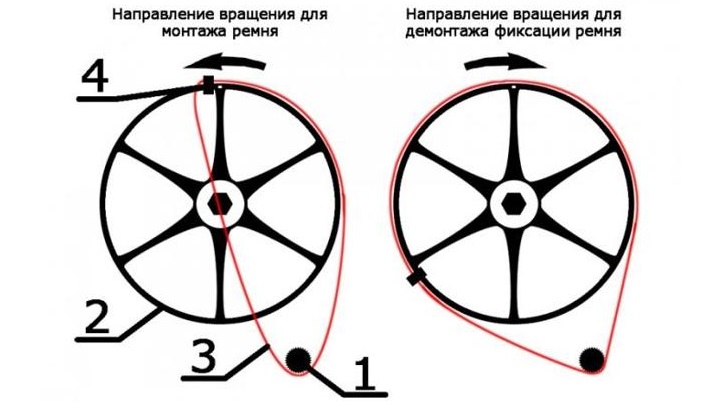

- place the new drive belt on the engine pulley;

- Pull the rubber band onto the drum pulley, slowly turning the “wheel”.

The belt should be positioned exactly in the middle of the drum pulley. If it is shifted to the side, align the position of the elastic. To do this, move it a few “streams” to the side on the electric motor pulley.

After replacing the belt, check the operation of the SMA. First spin the drum by hand. Then, without putting back the side wall, start the “Spin” mode and observe the washer. If all is well, assemble the body.

How to choose the right belt?

In fact, replacing the rubber band on a top-loading machine is quite simple. Ideally, if the markings on the old strap have survived, then finding a similar part will not be difficult.

Always look at the markings of the old drive belt - this will help you avoid mistakes when purchasing new components.

If the machine has been in use for a long time, there is a possibility that the markings on the belt have worn off. Then you will have to select components based on the model of the washing machine. You can see the name of the “vertical”, as well as the serial number, on the information sticker (available on the SMA case) or in the instructions for the equipment.

All manufacturers of drive rubber bands for SMA use the same marking. The first 4 digits indicate the length of the belt, the letter following is its profile, and the last digit is the number of wedges. The most popular companies producing similar components for automatic machines are Optibelt, Hutchinson, Megadyne, Dayco.

What is the difference between vertical SMA drive belts:

- type - they are wedge-shaped and poly-wedge;

- profile (distance between strips). In the markings this will be marked with the letter J or H;

- number of wedges (from 3 to 8) and ridges (from 4 to 9);

- length (this is the most important criterion when choosing a drive belt).

Thus, if the damaged belt is marked 1965H7 Hutchinson, then you can purchase a part from any other manufacturer, but always with a similar length/profile/number of wedges. For example, the 1965H7 Optibelt elastic band is quite suitable.

As an example, consider the markings of some belts and washing machines compatible with them:

- Hutchinson 1204H8 PHE belt 481235818167 is suitable for Whirlpool models AWA 1000 856110029203, AWA 1000 856110029200, AWA 5067 856150629277, AWA 5068 856150629286, AWA 5069 856150629296;

- the Optibelt EL 1265 J4 strap can be installed on the Indesit WG421TPR, W43T washing machine;

- drive belt 1110 J5 is designed for Indesit W43T, WD622 models;

- drive belts types EL 1270 J3, EL 1270 J4, EL 1270 J5 are suitable for Samsung washing machines S621, S821, S832, S852, P805J, F813J, F1015J, P1005J, 1091, 1100F, P1405J, SWF1200F, P8091, P8021, SWF 1000.

You can also try calling the service center and asking the specialists which belt is suitable for your washing machine. Usually masters do not refuse oral consultation.Sometimes they even offer to order components through them - the price is not much different from the retail price, since the stores give the companies a good discount.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment