How to replace the drum cross of a Samsung washing machine

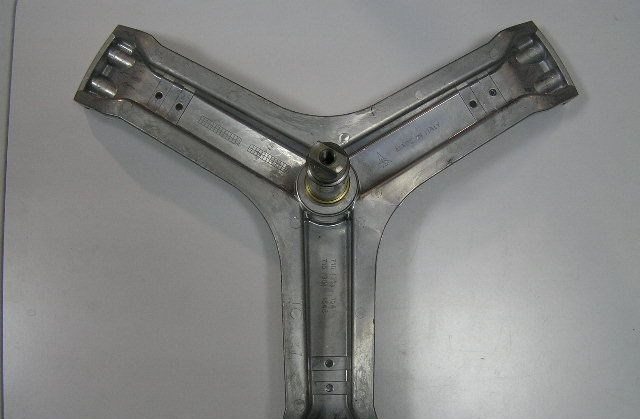

The cross is a part made of soft metal with which the CMA drum is attached to the shaft. It is constantly under stress, which over time leads to deformation and breakage of the element. The spare part cannot be repaired; it will have to be replaced.

The cross is a part made of soft metal with which the CMA drum is attached to the shaft. It is constantly under stress, which over time leads to deformation and breakage of the element. The spare part cannot be repaired; it will have to be replaced.

Let's figure out how to replace the cross on a Samsung washing machine. We'll tell you how to get to the part and what tools will be needed during the dismantling process.

Removing external housing elements

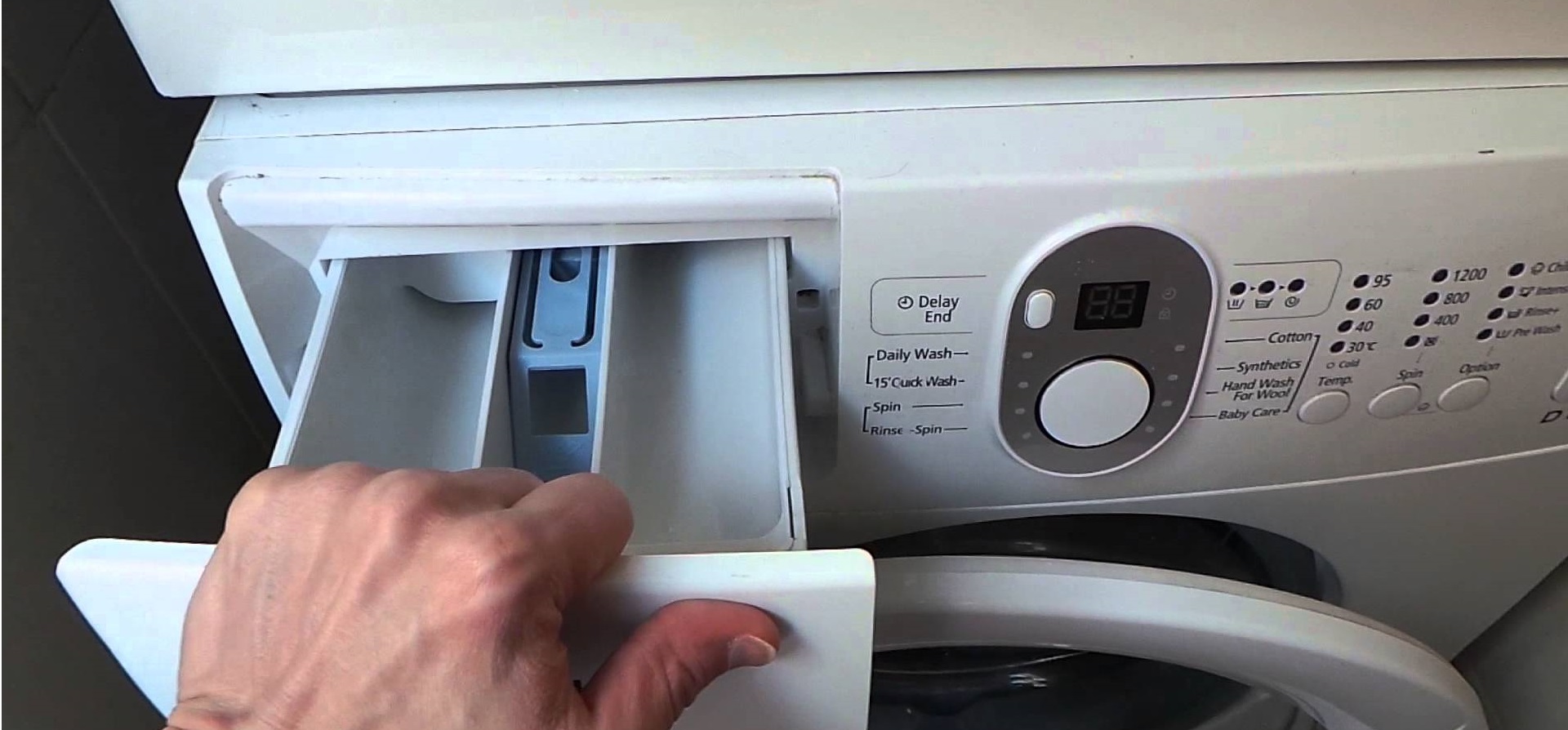

To replace the tank crosspiece, you will have to completely disassemble the washing machine. First of all, the external elements of the case are dismantled: the top and front panels, the powder receptacle, and the “tidy”. During these works, it is enough to have a Phillips and slotted screwdriver on hand.

Before you begin disassembling the case, be sure to turn off the power to your Samsung washing machine.

The work of replacing the crosspiece is quite complex and time-consuming. However, if you follow the instructions, you can repair the washing machine yourself. At the first stage, the algorithm of actions will be as follows:

- unplug the machine;

- turn off the tap responsible for supplying water to the washing machine;

- disconnect the drain and inlet hoses from the machine;

- move the SMA to the center of the room so that it is convenient to work with it;

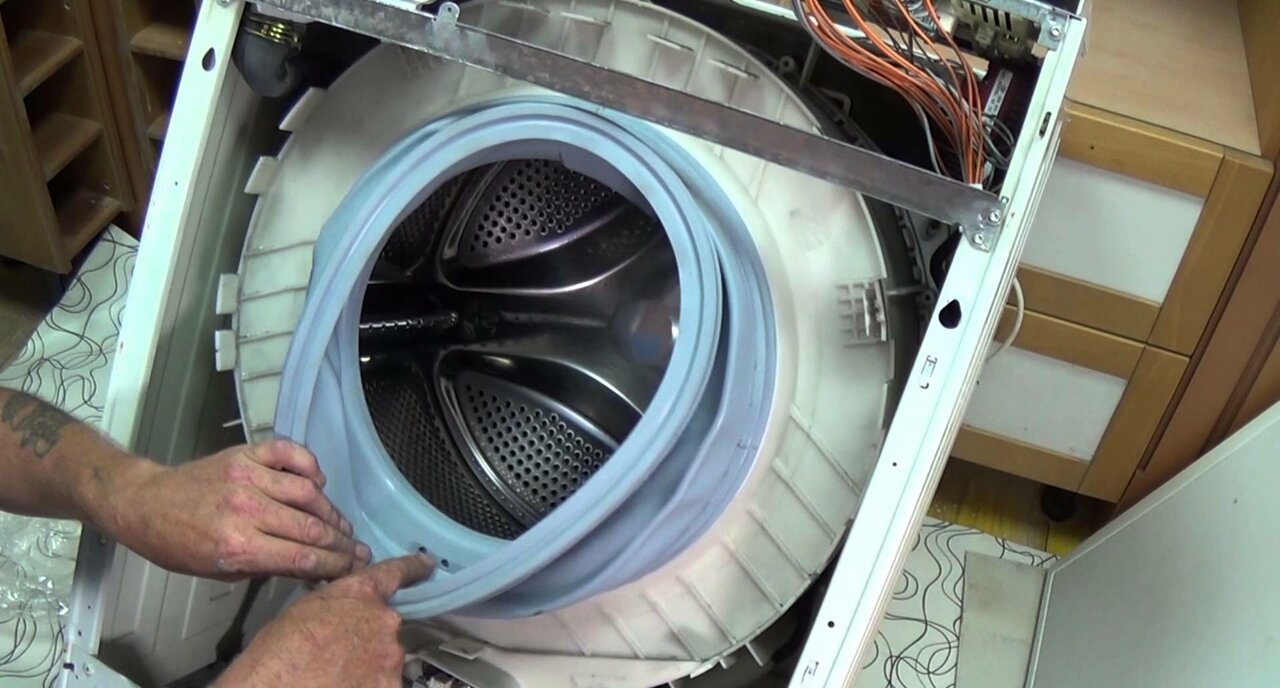

- open the hatch door, using a slotted screwdriver, remove the clamp securing the drum cuff;

- tuck the rubber seal inside the drum;

- remove the powder receptacle from the machine;

- remove the bottom trim panel of the washing machine, making sure to remove the fasteners;

- unscrew the garbage filter (be careful, when removing the plug, water may flow out of the machine);

- remove the bolts holding the SMA housing cover;

- remove the top panel;

- Unscrew the screws located around the perimeter of the control panel;

- take a photograph of the connection diagram of the device contacts to the electronic module;

- disconnect the wiring and move the control panel to the side;

- Unscrew the bolts holding the front wall of the washing machine (they are located along the entire perimeter of the panel);

- remove the front wall of the case, having first disconnected the contacts from the hatch locking device;

- remove the iron panel on top of the washing machine (it is located in the place where the tidy is attached);

- Unscrew the bolt holding the water level sensor, remove the pressure switch from the SMA housing;

- Unscrew the screws securing the intake valve, remove the chips from it;

- Remove the dispenser hopper along with the inlet valve and pipes.

When disconnecting the contacts from the internal parts of the SMA, take a photograph of the wire connection diagram so as not to make mistakes during further assembly.

This is the order in which the external elements of the body of a Samsung washing machine are dismantled. If this is your first time repairing a washing machine, please read the instructions for the equipment before starting work. This way you will be able to understand the structure of the SMA and get an idea of where which nodes are located.

We remove parts that interfere with removing the tank and drum

To replace the crosspiece, you need to remove the “tank-drum” assembly from the washing machine. Having disassembled the body of the automatic machine, you will see the container and all the elements connected to it. It is necessary to dismantle one by one the parts that will interfere with the removal of the tank.

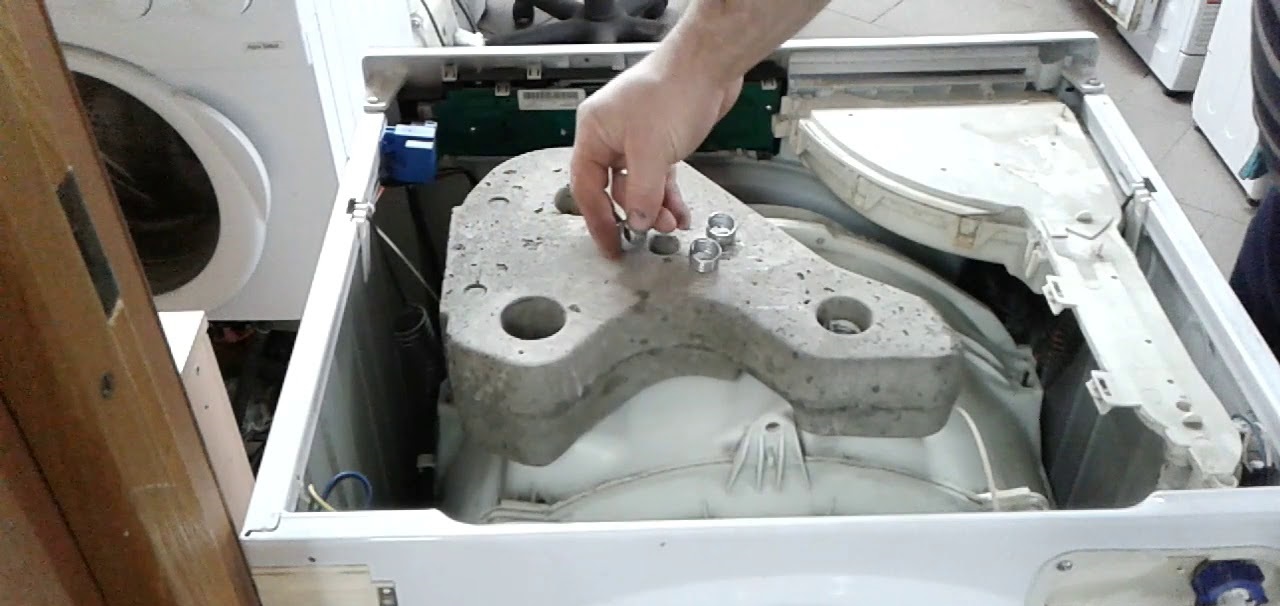

The first thing that will catch your eye is the upper counterweights.These are concrete blocks that provide stability to the Samsung washing machine. It is necessary to dismantle the weights by unscrewing the bolts securing them.

There is another counterweight located below. It also needs to be removed. The bolts securing the block are removed using a wrench, onto which a socket head of the required size is placed. Next, you need to dismantle the remaining internal parts that interfere with the removal of the tank.

The further algorithm of actions will be as follows:

- disconnect the heating element contacts from the tank (power red and blue wires, grounding and temperature sensor chip);

- unhook all twisted wires connected to the tank;

- unfasten the pressure switch hose;

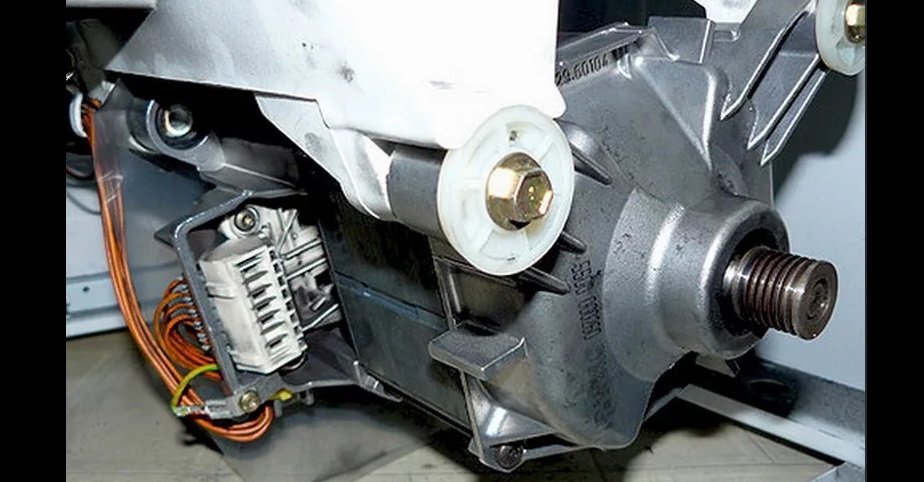

- disconnect the electric motor connector and the block itself that goes to the motor;

- unhook the drain pipe from the tank;

- remove the bolts securing the lower shock absorbers.

To work with the lower shock absorbers, you will need a 13mm socket. Unscrew the fixing bolts on each side. The container is held on top by four springs, which will also have to be unhooked. After this, you can begin to remove the tank-drum assembly.

After removing the tank, place it on a hard, flat surface, with the pulley facing up. Next, you need to remove the drive belt and disconnect the engine. Next, the shock absorbers are detached from the container.

The pulley does not need to be removed at this stage. Washing machine bins Samsung collapsible. This greatly simplifies the work - to halve a plastic container, you just need to deal with a few brackets.

We disassemble the tank, get to the cross

The next stage is disassembling the unit. It is very easy to halve the tanks of Samsung washing machines. The container is not solid, like some models from other brands. The parts of the tank are separate and connected by special fasteners.

Place the tank-drum assembly vertically, and remove the brackets one by one using a screwdriver. Usually this is 5-7 fastenings. By removing the clamps, you can halve the container.

The upper part of the tank can be removed immediately. Further work is carried out with the lower half. It will be necessary to remove the drum from it, behind which there is a cross.

Sometimes the cross is destroyed so badly that the drum can be easily pulled out of the tank, and the shaft itself remains in the plastic container. In any case, you will have to disassemble the structure completely. The algorithm of actions will be as follows:

- twist the nut securing the drum pulley;

- remove the drum “wheel”;

- push the bolt inward.

After this, you will be able to dismantle the damaged crosspiece. To do this, unscrew the three bolts holding it. If there is wear, pre-treat the fasteners with WD-40. A new replacement part is selected for a specific model of Samsung washing machine. Before installing the entire spare part, be sure to clean the insides of the tank and the back surface of the drum from plaque, dust and dirt.

It is also advisable to immediately check the condition of the bearing assembly. If the metal rings and oil seal are worn out, it is recommended to replace them at the same time as the crosspiece.

The new part is also secured in place with three bolts. Next, the drum with the cross is placed back into the tank. A pulley is attached to the shaft.

The next stage is assembling the plastic container. The upper half of the tank is placed on the lower half and the parts are tightened with staples. The bottom clip is placed first, then the top one, then all the others. Then the shock absorbers are put in place and secured with bushings.

Next, the machine is assembled in reverse order.The engine is attached to the tank, after which the unit is placed in the housing, and the tank is suspended from above by springs. The lower shock absorbers are secured with bolts. Then all previously removed wires, pipes and parts are connected to the container.

When assembling the machine, twist the wires as much as possible so that they do not hang or fray.

Next, the body of the washing machine is assembled. First, the front wall is fixed in place, then the control panel and finally the top cover. When finished, connect the machine to communications and run a test cycle. Make sure that the drum rotates without any extraneous sounds. Also make sure that the machine is not leaking. If everything is in order, the repair can be considered complete.

Crosspiece failure does not happen suddenly. Before this, users hear humming and extraneous noise while the machine is operating. Destruction of a part can occur due to:

- too hard tap water, which provokes scale formation;

- low-quality detergents used for washing;

- worn bearings (when the rings wear out, the crosspiece begins to deform).

Therefore, it is important to monitor the hardness of tap water and, if necessary, use softeners. You should also buy only high-quality household chemicals for SMA and do not overload the machine. Then such labor-intensive repairs can be avoided.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment