Replacing the crosspiece in an LG washing machine

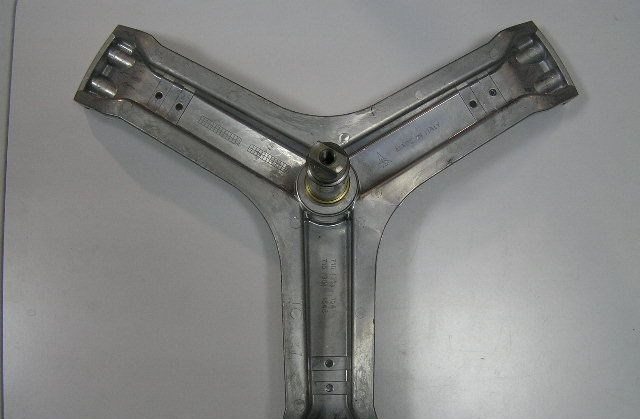

The crosspiece in a washing machine is a soft metal piece through which the drum is attached to the tub. Due to this, the part regularly experiences heavy loads and, as a result, becomes deformed or breaks, causing the need for repair. Replacing the crosspiece on an LG washing machine is impossible without removing it, so we will dwell on this issue in more detail.

The crosspiece in a washing machine is a soft metal piece through which the drum is attached to the tub. Due to this, the part regularly experiences heavy loads and, as a result, becomes deformed or breaks, causing the need for repair. Replacing the crosspiece on an LG washing machine is impossible without removing it, so we will dwell on this issue in more detail.

Causes of failure

In fact, the impact on the cross does not begin immediately; the bearings are the first to take the blow. Over time, they also wear out, beginning to emit uncharacteristic hums and grinding noises during washing. If problems with the bearings are detected and corrected in time, the crosspiece will remain undamaged and no repairs will be required, but if the situation gets worse, a comprehensive replacement will have to be made.

Another common cause is hard water. The compounds settle on the metal, forming scale and limescale. In some cases, the cause of the breakdown may be a manufacturing defect, but in this situation it is better to return the machine to a technical center if it is under warranty.

Let's start disassembling the SM

Before starting work, disconnect the washing machine from the mains and water supply. Then disconnect the intake hose (located on the back of the washer) and the drain filter (it can be found at the bottom of the front wall of the machine, inside the hatch). Also, for convenience, it is better to move the unit away from the wall and place it in a spacious place.

You can remove the part with your own hands in two ways: by unscrewing the top wall or the front one. In the latter case, the process of removing parts will be much more painstaking and time-consuming, so it is better to remove both.

- Unscrew the screws holding the top panel of the washer. Then push the lid in the opposite direction from you and lift it sharply. Now just set it aside so it doesn't interfere.

- Now you need to disconnect the control panel. To begin, open the powder tray and remove it by pressing the special pimp in the middle compartment of the dispenser. Now, through the resulting niche, unscrew all the screws holding the control panel. Release the plastic clips holding the wiring in place. Don't forget to somehow mark the location of the wiring around the perimeter so that you can put everything back in place correctly later. Disconnect the wires and remove the panel.

- Refer to the bottom of the front wall. It is not difficult to remove the “plinth” panel, especially since you should have already done this by unscrewing the drain filter.

- Remove the hatch rubber. To do this, bend its edges a little in search of a clamp. It can be either plastic, in which case it is enough to “unfasten” the special lock, or solid metal, then pick it up with a screwdriver or other sharp object and remove it. The cuff without a clamp can be easily removed.

- When the cuff is removed, all that remains is to remove the lock. To do this, unscrew the bolts holding the device in the niche. Through the hole that was previously blocked by the cuff, push the lock and remove it.

- The front wall is almost finished. To remove the main panel, all that remains is to unscrew all the bolts and screws.

Important! It is advisable to remember what and which screws were held in place, otherwise confusion may arise later and you will not be able to put the device back together.

If you have already removed the powder receptacle, also remove the pipe connecting it to the tank.After this, you can easily remove the inlet valve (just remember to unscrew the bolts from the back). It is also advisable to remove the counterweights, since they are very heavy and will prevent you from quickly performing operations with the machine yourself. The counterweights are secured with large screws.

The last thing left is to remove the back cover and what’s under it. Everything is simple here: unscrew the bolts and remove the panel. Disconnect one by one:

- wiring from the heat element;

- pressure switch tube from the tank;

- clamp from the drain pipe;

- wiring from the motor, then unscrew the screws and remove the motor itself;

- remove the shock absorbers.

Now nothing holds the tank, it just hangs on special hooks. It can be easily removed through the front of the SM by lifting it a little and then pulling it towards you.

Tank and drum

The tank can be removed. First, remove the cuff. After this, turn the tank with the pulley towards you and unscrew the bolt holding it, remove the pulley. Remove all screws around the perimeter. When there are no bolts left, you can easily remove one half of the tank and get to the drum.

Now proceed directly to inspecting the cross. Perhaps it does not need repair at all, and it's all about the bearings. Be that as it may, purchase a new part, especially for a specific model of washing machine.

Changing the cross

Now let's learn more about how to change the crosspiece. It is attached to the drum with three self-tapping screws. Due to scale and other hard water problems, the bolts can become tightly “stuck” and it will be difficult to remove them. WD-40 liquid will help you with this; you need to pour it on stubborn elements and wait about half an hour. The plaque should become limp, after which you can safely unscrew the screws.

Now let's learn more about how to change the crosspiece. It is attached to the drum with three self-tapping screws. Due to scale and other hard water problems, the bolts can become tightly “stuck” and it will be difficult to remove them. WD-40 liquid will help you with this; you need to pour it on stubborn elements and wait about half an hour. The plaque should become limp, after which you can safely unscrew the screws.

Next, removing the cross is quite simple: take a hammer and a screwdriver. Gently tap the part or pry it with a screwdriver to remove it from the grooves of the drum. Now you can buy and install a new crosspiece.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment