Inlet solenoid valve for washing machine - check and replacement

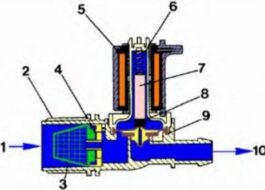

The fill valve is needed to draw water into the machine so that it can wash. It has two functional positions:

The fill valve is needed to draw water into the machine so that it can wash. It has two functional positions:

- Open,

- And closed.

Most often it is in the closed position. When current flows through its coil, an electromagnetic field is generated. This field creates the actions required to open.

That is, it tightens the rod and the membrane comes into the open state. And the water enters the dispenser hopper, where it washes away the washing powder. And then it is poured into the tank of the machine along with the powder. When the required amount of water has been collected, electricity stops being supplied to the coil and the water supply stops.

Types of valves

There are several types of valves for washing machines. Some of them have 1, others - 2 and others - 3 coils (sections). Each section is a separate path for water flow. The number of these sections is associated with the different structure of washing machine models. The design of some requires one coil, others two, and so on.

There are several types of valves for washing machines. Some of them have 1, others - 2 and others - 3 coils (sections). Each section is a separate path for water flow. The number of these sections is associated with the different structure of washing machine models. The design of some requires one coil, others two, and so on.

In those models where there is only one valve, the direction of water supply is controlled mechanically. control lever. It forces water to flow into different sections of the plastic dispenser. This design is typical for older models of washing machines. In them, the single-valve system coexists and cooperates with the command apparatus.

More modern washing machines have an electronic control module. But there is no mechanical drive. They use valves with two or three coils (sections).One coil creates a supply of water to one section of the plastic dispenser of the washing machine. The other is in the second. And in order to create a supply to the third section, a third coil is needed. Or in the case of a two-coil valve, this is done by turning on both coils at the same time.

How to check the intake valve?

Let's look at the issue of checking the valve. In order to make sure that this part of the washing machine is working, you need to remove it. Then connect the inlet hose to the inlet valve. Next, you need to apply 220 volts to all coils in turn. If the valve is working, then when electricity is applied it should allow water to pass through. That is, open up.

Let's look at the issue of checking the valve. In order to make sure that this part of the washing machine is working, you need to remove it. Then connect the inlet hose to the inlet valve. Next, you need to apply 220 volts to all coils in turn. If the valve is working, then when electricity is applied it should allow water to pass through. That is, open up.

And if there is no electricity supply, do not let water through. That is, to close. You need to be very careful when conducting this experiment. After all, if water gets on live wires, there will be a short circuit. Therefore, you should protect yourself as much as possible. You should also not forget that during this test water will flow. It must be sent to some pre-prepared container.

- First you need to check the intake valve screen. If there is a blockage inside it, it may interfere with the flow of water. This valve part must be removed and cleaned. And then return it to its original place. If you don’t do this, water will flow into the machine very slowly or not at all.

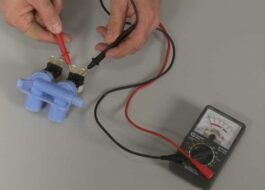

- If the valve does not open when electricity is supplied, then most likely its coil has burned out. In order to verify the presence or absence of this breakdown, you can use a multimeter (tester). They need to measure resistance. Normal resistance is approximately 2-4 kOhm. You can change the coil.If there is a spare valve, you can remove it from it. If not, you can order a new coil or a whole valve. Usually it is quite inexpensive.

- It is also necessary to determine whether there are pressed plastic inserts in the fittings. They reduce the amount of water entering the machine at a time. They are usually used on the intake (inlet) valve fitting. The one that is busy supplying water to the dispenser section intended for rinsing. If the insert falls out, then the water pressure increases. And it ends up in the dispenser department in too much quantity. A faulty valve is easier to replace than to repair.

How to change the valve?

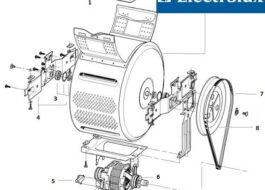

Most often, the valve is located at the top of the machine on its back wall. In order to get to it, we need to remove the upper part of the case (cover). The cover is fixed using 2 screws located at the back. Unscrew them. Then push the cover from the front towards the back wall. Then you can remove it.

If you have a top-loading machine, the valve is usually located at the bottom of the rear of the machine. In order to get to it, you need to remove the side of the washing machine body.

Be sure to turn off the water supply before removing the valve. Then disconnect the wire terminals and hoses from it. If the latter are fixed with disposable clamps, then you can prepare several disposable clamps in advance or use previously stored reusable ones.

After this, tighten the fixing bolts. In some models, the inlet valve is secured with latches. In this case, you need to pull back the locking part of the latch, turn the valve and pull it out.

Valve replacement video

Interesting:

8 reader comments

Washing machine IWse-5105 does not work, the on/off button does not work The machine takes in water and then drains it without stopping the screen H2O flashes beeps BUTTONS ARE BLOCKED help PLEASE WHAT IS THE TROUBLE

I CHANGED THE CONTROL MODULE FROM ANOTHER WASHING MACHINE THE OFF \ OFF BUTTON WORKED and that’s all, I checked the pressure switch, it clicks when you blow the hose without clogging, the tester was able to ring only two contacts out of 3 Ten and the sensor is normal, I removed it and checked it

If it writes n2o, then the machine does not see the water. Remove the filter mesh from the water supply and try without it. The supply hose and water supply pressure are also subject to check.

The inlet valve is broken, the washing machine fills with water, even when turned off. For now we are blocking the central pipe. But if it is not yet possible to change the valve, is it possible to wash it if you open the central pipe?

Change the intake valve.

Do you have 2 valves? If yes, then clamp the rubber hose from the faulty valve inside the washer and use one. You just need to swap the valve power connectors, depending on the washing mode. And the water will only flow into one powder/conditioner tray.

Or you can turn off one valve so as not to pinch the hose.

Hello, can anyone tell me if it is possible to remove the valve from an Indesit machine and install it on a Bosch?

Is it possible to install another valve according to the markings?