How does an Electrolux top-loading washing machine work?

When household appliances work normally, users are not even interested in how this or that device works. Usually people think about the “structure” of the washing machine when a problem occurs. Knowing what components the machine consists of, where the parts are located and how they interact with each other, you can perform diagnostics yourself without calling a technician.

When household appliances work normally, users are not even interested in how this or that device works. Usually people think about the “structure” of the washing machine when a problem occurs. Knowing what components the machine consists of, where the parts are located and how they interact with each other, you can perform diagnostics yourself without calling a technician.

Therefore, we will analyze in detail the structure of the Electrolux top-loading washing machine. Understanding what a “home assistant” consists of, it will be easier to find and eliminate the cause of the malfunction. Let us explain which parts of the vertical are responsible for what.

What parts is the machine made of?

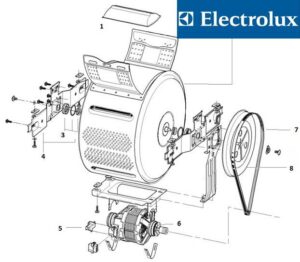

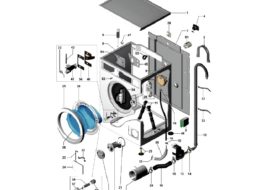

Automatic Electrolux machines of vertical type have a similar structure. There may be differences, for example if some model is equipped with a steam generator, but usually they are minor. The instructions for the equipment describe the device of the SMA, and also present a diagram of the location of the main components and parts of the washing machine. Therefore, it is recommended to start by reading the user manual.

Any vertical Electrolux machine contains:

- electric motor;

- tachometer;

- control module;

- tank;

- metal drum with doors for loading/unloading laundry;

- drain pump;

- snail;

- rubber pipes and hoses;

- drive belt;

- detergent dispenser;

- shock-absorbing elements (springs and struts - vibration dampers);

- a heating element;

- drain filter;

- dashboard;

- concrete weights;

- thermistor;

- drum cuff;

- lid locking device;

- water fill valve;

- pressure switch

Almost all of the listed elements are hidden inside the metal body of the vertical. The control panel with a rotary programmer and buttons is located on the lid of the washing machine. There is a tray under the washing machine.

To diagnose SMA, it is important to understand how the main parts of the washer work and where they are installed.

Therefore, we will analyze in detail the purpose and operating principle of each part of the Electrolux vertical. We will describe where the element is located, what it consists of and how to check its functionality.

Control board

The “brain” of the washing machine is the electronic module. The control board controls all other parts of the SMA. If it fails, the operation of the vertical line stops completely.

Electronically controlled automatic machines operate as follows:

- the user selects the washing program using the selector, then adjusts the algorithm settings using buttons on the dashboard;

- the electronic module accepts commands and starts the mode with the specified settings;

- the necessary components of the washing machine begin to work;

- The control unit monitors the process, introducing new nodes into operation and disabling unnecessary nodes as the cycle progresses.

The control board starts the operation of the automatic machine. Only after a signal from the module does the inlet valve open and begin to let water through, the motor creates impulses and spins the drum, and the pressure switch measures the liquid level in the tank. Every action of the washing machine is controlled by the “brain” of the SMA.

There are many semiconductors and traces located on the control board. Each element is responsible for the operation of a specific unit of the washing machine.If the electronic module notices the slightest deviation from the norm, it urgently interrupts the cycle being performed by the washing machine and notifies the user of the problem. The display shows an error code corresponding to the malfunction.

One of the most unpleasant and costly breakdowns of a vertical Electrolux machine is damage to the electronic module. With such a malfunction, the “behavior” of the washing machine can be unpredictable. If the control unit fails, the equipment can:

- do not respond to user requests;

- freeze at any stage of the cycle;

- do not turn on;

- do not start collecting or draining water, etc.

In such a situation, it can be very difficult to find the cause, since such “symptoms” can appear not only when the control unit is damaged. Therefore, if the machine does not take in water, you will have to check the inlet hose, the inlet valve, the pressure switch, and only then the electronic module. If the drum does not spin, inspect the drive belt, motor, pulley and, finally, the circuit board.

Without experience working with electronics, it is better not to even try to repair the control module yourself, otherwise you may damage it even more.

This is one of the breakdowns of SMA Electrolux, when repair at home will be almost impossible. In this case, it is better to seek help from specialists. It will not be possible to competently perform diagnostics without knowledge and experience, and to repair a board, professional equipment and modern software are usually required.

Elements of the filling system

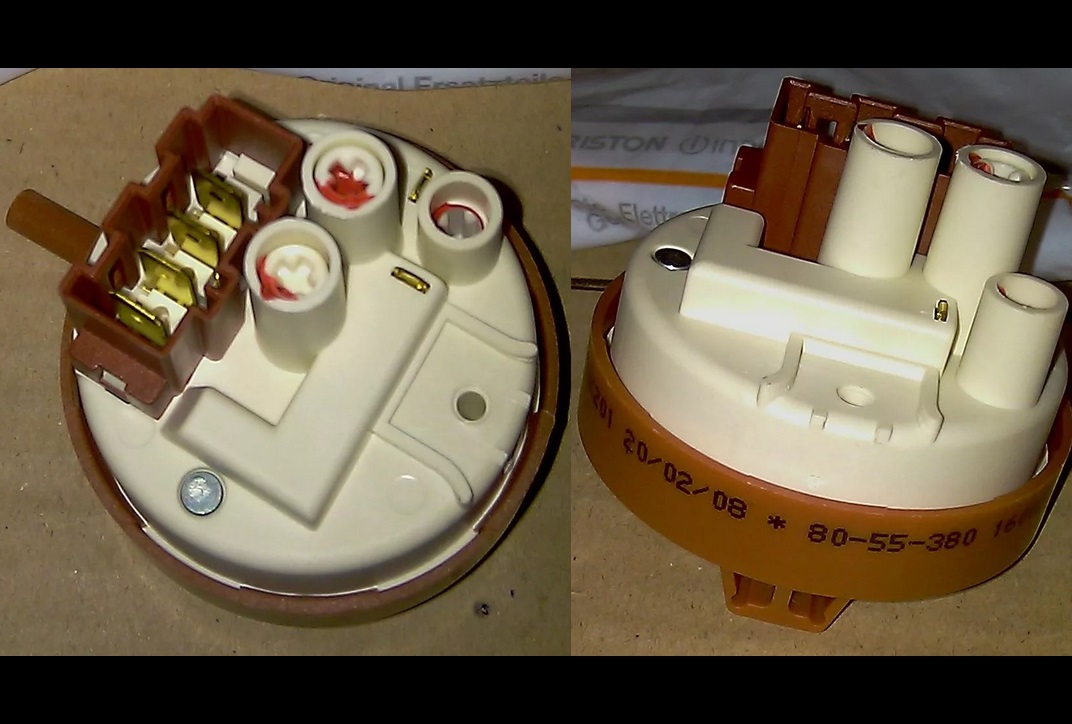

Any machine cycle begins with water entering the tank. At this stage, the fill valve and pressure switch are activated. Immediately after the user presses the “Start” key, the device begins to operate.How the drum is filled:

- the control module receives a signal about the need to draw water;

- the pressure switch measures the pressure in the system and transmits information to the “brain”;

- the electronic unit receives information about the empty tank and gives the command to fill with liquid;

- the system sends a pulse to the fill valve, its membrane is triggered, opening the valve;

- water begins to flow into the machine through the inlet hose;

- a pressure switch controls the water level in the tank;

- when there is enough water, the sensor informs the control module about this;

- the “brain” of the machine stops supplying voltage to the solenoid valve;

- the inlet valve diaphragm lowers, the flap closes, and liquid filling stops.

All elements of the filling system work harmoniously. The pressure switch controls the fullness of the tank, preventing overfilling or underfilling. The “brain” coordinates the work of parts, receiving and transmitting signals.

What problems might occur at this stage? Often the inlet filter on Electrolux verticals gets clogged. Because of this, the machine either cannot fill itself or does so very slowly, and the module generates an error. The mesh needs to be cleaned every six months.

It is also possible that the intake valve itself may fail. This part cannot be repaired; it needs to be replaced. Sometimes the pressure switch stops functioning, in which case you will have to either clean the pressure tube or install a new level sensor.

Electric motor

The engine is the “heart” of any automatic machine. The motor starts the drum, spinning it. The rotation speed is controlled by a tachogenerator mounted on an electric motor. Without a tachometer, the cylinder would spin chaotically, without controlling either the direction of movement or the number of revolutions per minute.

Some modern Electrolux top-loading AGRs are equipped with inverter motors.

In inverter machines, the motor is connected directly to the drum shaft. This connection is safer and much more efficient. In commutator machines, motor impulses are transmitted to the drum wheel using a drive belt - it acts as an “intermediary”.

The cost of inverter machines is higher. The design with a drive belt is much cheaper, but at the same time less reliable, since:

- the drive belt tends to stretch, tear and fly off the pulley;

- commutator motors contain electric brushes, which wear out over time and require replacement;

- collector machines consume more electricity during operation.

The electric motor of Electrolux verticals does not fail very often. The only thing is that the commutator brushes wear out over time, so after 3-4 years of operation of the SMA they will have to be replaced. Sometimes the motor winding breaks, but this is a very rare problem. The engine is tested for performance with a multimeter.

Electric heating element

The heating element is responsible for heating the water to a given degree. The user just needs to select the washing program and temperature, and the control module will receive this information and transmit it to the heating element. He, in turn, will get to work.

A thermostat works in conjunction with the heating element. This is a sensor that monitors water temperature. As soon as the desired degree is reached, the thermistor transmits information to the control module and it turns off the heater.

The temperature sensor is installed near the heater. A thermistor is a small metal tube. The thermostat and heating element are connected by wires.

Often, Electrolux users encounter heating element burnout.If you don't soften hard water and don't descale your machine, deposits will primarily accumulate on the heater. This disrupts the thermal conductivity of the part, and it fails.

It is also not recommended to run more than two high-temperature modes in a row. This will ensure maximum load on the heating element. And if the tube heater is not allowed to cool before the next cycle, it may burn out.

What are the pieces of concrete and springs inside for?

During rotation of the drum, centrifugal force arises, for which special elements are provided in the washing machine. Shock absorbers weaken outgoing vibration, and counterweights ensure the stability of the device. If not for these details, the body of the washing machine would wobble in different directions, and the “home assistant” would definitely jump around the room.

The stability of Electrolux vertical SMAs is ensured by:

- vibration dampers or dampers. They are equipped with a built-in spring connecting the tank and the washer body;

- springs. On them, the SMA tank is fixed at the top and side;

- counterweights. The blocks are located in several places; they weigh down the body, fixing the machine in one place.

Over time, shock-absorbing elements, constantly experiencing external influences, wear out. Dampers are damaged, springs are stretched, counterweights are loosened, and sometimes deformed. It’s easy to check the condition of the vibration damper struts - press firmly on the tank and lower it. He should immediately return to the starting position without jumping up and down.

It is even easier to assess the condition of the counterweights. Remove the MCA cover and side walls. This will open up access to concrete blocks that can be easily inspected.

Wear of the shock absorber system will be faster if the washing machine is installed incorrectly and not level. It is important to initially adjust the position of the SMA body so that it stands without distortion.

You can replace worn-out elements of the shock-absorbing system with your own hands. To do this, you need to buy new components, partially disassemble the vertical frame body and install serviceable dampers in place of the damaged ones.

Hatch cuff and lock

Each vertical locker has both a mechanical and an electric lock. The first one “snaps” when the lid is closed, when the tongue fits into the groove. When the cycle starts, the machine is additionally blocked by an electronic device.

It is the UBL that does not allow you to open the lid of the SMA Electrolux during washing.

The hatch locking device will lock the panel until the end of the cycle. Only when the machine finishes working will the electronic lock turn off. Then you can open the lid of the washer.

The tightness of the vertical SMA drum is ensured by a rubber seal. The cuff is located at the edges of the cylinder. It completely covers the gap between the tank and the body, thereby preventing leaks.

When the sealing rubber is deformed, water will begin to flow out of the washer. In this case, you cannot operate the machine. The cuff must be replaced immediately, as the system must always be sealed.

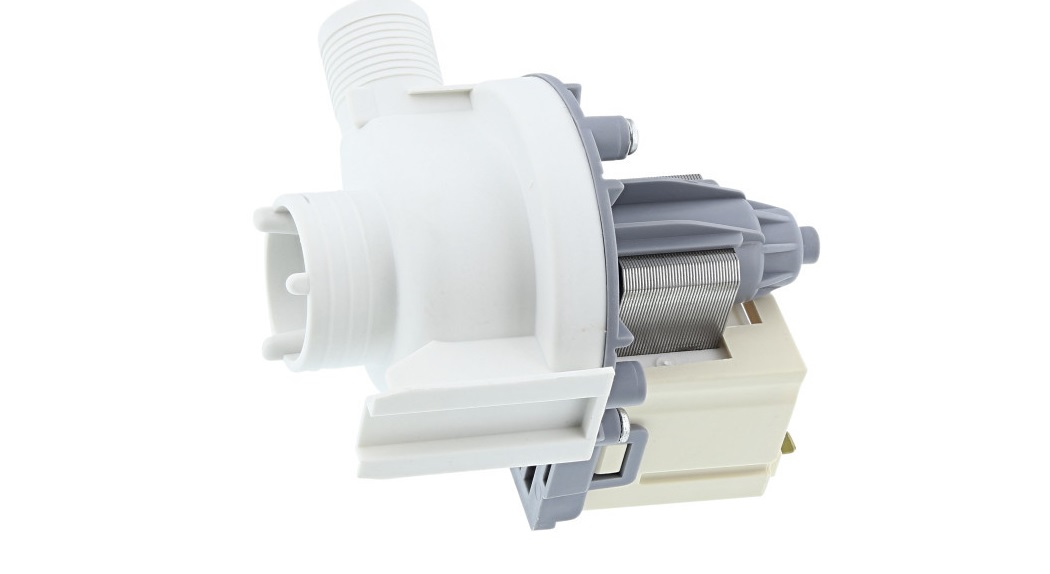

“Motor” removing impurities

A very important step is removing waste liquid from the tank. The machine drains several times per cycle. For example, after soaking, during the main wash, before rinsing. The drainage system includes several elements:

- pump;

- hoses and pipes;

- garbage filter;

- drainage sleeve.

A drain pump pumps water from the tank into the sewer.There are two types of pumps in Electrolux washing machines:

- synchronous;

- asynchronous.

Regardless of the type, the operating principle of the pumps is the same. They are activated by a small motor that spins the impeller. The pump is fixed on the cochlea. Drain pipes are connected to it to pump water from the tank to the sewer.

A garbage filter is provided at the bottom of the vertical SMA drum. It collects lint, threads, hair, foreign objects forgotten in the pockets of things, preventing clogging of the drain pipe and pump. Be sure to periodically clean the filter element - approximately once every 2-3 months.

Drainage problems with Electrolux vertical units most often occur due to blockages. The garbage filter, pipes and drain hose, and pump impeller become clogged with dirt. This is why it is so important to periodically clean your washing machine. Failures due to pump failure are rare.

Tank and drum

The tank is the largest element of the washing machine. In a plastic container, water is mixed with the powder, and then the soap solution enters the drum. For vertical machines, the reservoir is located with the opening facing upwards, for frontal ones – forward.

For vertical Electrolux washing machines, the drum can hold from 4 to 8 kg of laundry, this depends on the SMA model.

If the tank of vertical Electroluxes is made of plastic, then the drum is made of stainless steel. This material does not suffer due to constant contact with water. To avoid the appearance of an unpleasant odor from the machine, you should constantly ventilate the washing machine, leaving its lid ajar.

The surface of the drum is perforated. Water flows from the tank through these holes. There are also plastic rib punches inside the metal container.These blades are designed for stirring laundry and foaming detergents.

Powder box and hoses

Also, any vertical rack has a detergent dispenser. It is located under the lid of the automatic washing machine. The Electrolux powder receptacle has three compartments as standard:

- for pre-wash (indicated by Roman numeral I);

- for main wash (symbol II);

- for conditioner-rinse aid (the compartment is marked with a flower).

It is important not to confuse the compartments, since detergent is removed from each compartment at a certain stage of the cycle. It would be completely wrong to wash things with conditioner and rinse them with water and powder. In this situation, the wash will have to be started again.

Water, pouring through the inlet valve, immediately goes into the powder receiver, and only then, through the pipes, into the tank and drum. Inside the machine there is a whole system of hoses through which liquid circulates. They can be compared to blood vessels in the human body.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment