How does a Whirlpool washing machine work?

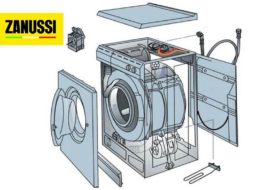

The design of all frontal washing machines is almost the same. Of course, there are differences in the form of an additional door for reloading laundry, more or less advanced “firmware” for the presence or absence of a drive belt or display, but the basic “equipment” is identical. The principle of operation of the units and components of the front-end units remains unchanged. The structure of the Whirlpool washing machine is quite simple, and using the example of equipment from this brand, it is easy to understand what main parts all machines consist of. Let's look at the structure of a typical washing machine.

The design of all frontal washing machines is almost the same. Of course, there are differences in the form of an additional door for reloading laundry, more or less advanced “firmware” for the presence or absence of a drive belt or display, but the basic “equipment” is identical. The principle of operation of the units and components of the front-end units remains unchanged. The structure of the Whirlpool washing machine is quite simple, and using the example of equipment from this brand, it is easy to understand what main parts all machines consist of. Let's look at the structure of a typical washing machine.

List of structural elements

It is advisable for users to know how the washing machine works. If suddenly the equipment fails, then by understanding the principle of operation of the equipment and understanding what the machine consists of, you can independently identify the malfunction and eliminate it.

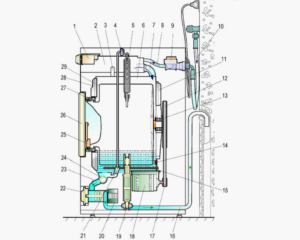

There is nothing complicated about the design of washing machines. Any front camera has:

- frame;

- counterweights;

- fastening metal strip;

- shock-absorbing elements: springs and dampers;

- tank with drum;

- hatch door;

- cuff with internal and external fixing clamp;

- motor (unlike the model, it can be inverter or commutator);

- drive mechanism (for machines equipped with a “collector”);

- dashboard;

- water pump;

- garbage filter;

- a heating element;

- temperature sensor;

- control module;

- pressure switch;

- inlet valve;

- hatch blocking device;

- inlet and drain hose;

- “tank-drain pump” hose;

- bearing unit;

- detergent dispenser.

The “insides” of the washing machine are connected to each other by wires and pipes.

The machine also contains rubber seals, various clamps, terminals and connectors. These are the main elements that ensure the normal functioning of the Whirlpool washing machine. Let's figure out what each part is responsible for. Let us describe the operating principle of the washing machine.

Coordinated work of parts

Uninterrupted operation of the equipment can only be ensured if all parts properly perform their assigned functions. Commands are issued to the internal elements by the main control module, which also controls the entire washing process. The electronic unit sets the sequence of cycle stages and ensures interaction between the main components and components.

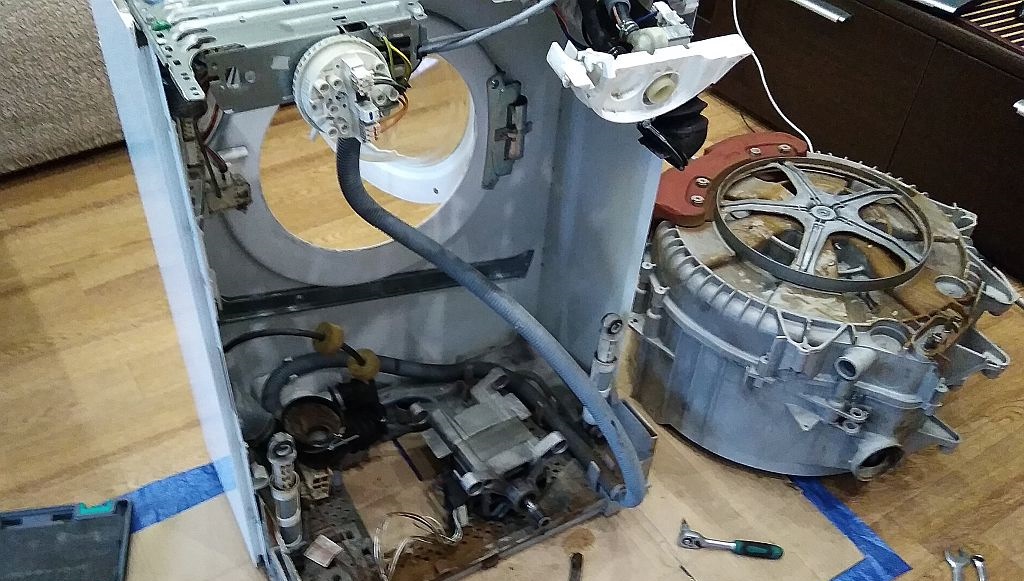

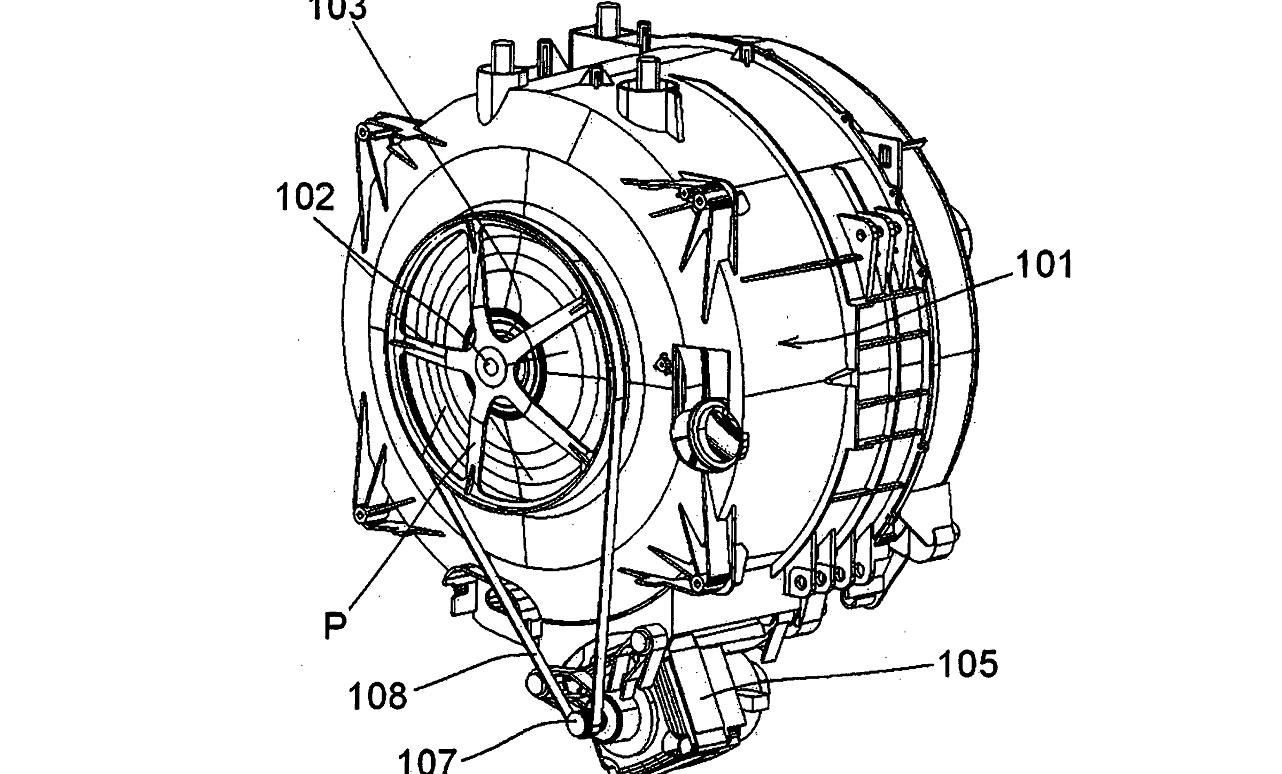

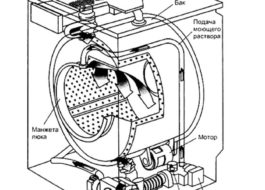

The most impressive element of a Whirlpool washing machine is the tank. In models of this brand it is made of plastic. More expensive machines are equipped with a stainless steel tank. The container is supported in the housing using springs and dampers. A drum is placed in the tank - a container made of stainless steel with a “porous” surface. This is where dirty laundry is placed for washing. The “centrifuge” is spun by an electric motor thanks to a drive mechanism.

The drive belt is placed on a small motor pulley and a large drum “wheel”. So, the elastic band receives impulses from the engine and spins the drum. Due to the high rotation speed, the laundry is washed.

It is important to understand what happens after the user runs the desired cleaning program. The “brain” of the machine opens the inlet valve, water begins to flow into the system. At the same time, the pressure switch controls the degree of filling of the machine, and when the desired level is reached, it sends a signal to the module. The electronic unit gives the command to stop dialing.

Next, the control board activates the heating element, which heats the water to the temperature specified by the settings. Afterwards, the “brain” controls the washing stages, and at the end “orders” the drain pump to pump out water from the system, and the engine to accelerate the drum to maximum speed for spinning.

This is how every wash is done. Depending on the program selected by the user, additional steps may be added, such as soaking or double rinsing.

This is just a general idea of how a washing machine works. For a detailed study, it is worth considering each node of the machine and its functions separately.

Containers for washing

The largest capacity in an automatic machine is the tank. For Whirlpool washing machines, it is made of plastic - due to this, a lower price of the equipment is achieved. Some brands offer equipment equipped with stainless steel tanks - this is stronger and more reliable, but the final cost of such models is much higher. The tank sits level in the front-facing housing. It is rare to find models of washing machines in which it is located at an angle.

A metal drum with a “porous” surface is built into the tank. Water is poured through the pipes into the tank, where it is mixed with the powder, and through the holes it flows to the laundry. In addition to the “holes”, there are plastic ridges on the drum walls - they provide better cleaning of the fabric.

The tank-drum assembly is damaged extremely rarely. These are very reliable parts of the Whirlpool washing machine. Failure by the user to comply with basic rules can lead to dire consequences.

For example, a paper clip, pin or hairpin forgotten in a pocket can get stuck between the drum and the tank and pierce the plastic.The same effect can be achieved when a bone falls out of a bra. Therefore, it is very important to check things before putting them in the machine, and wash potentially dangerous items in special bags. The unit is also damaged if the maximum permissible load weight is not observed. If you systematically “stuff” all 8 kilograms of laundry into a 6 kg washing machine, this will not lead to anything good.

Where does the hot water come from?

Most washing machines are connected to a cold water supply. The heating element is responsible for heating water in automatic machines. The tubular element is located under the tank. To gain access to it, you need to remove the housing cover and the back wall, and remove the drive belt.

The heating element is considered a rather vulnerable part of a Whirlpool washing machine.

If the user neglects the recommendation to periodically clean the “insides” of the machine, then the heating element will have to be changed quite often. The heater is constantly in contact with water, which contains heavy impurities. As a result, scale appears on its surface. A layer of limescale impairs the thermal conductivity of the element, leading to overheating of the part.

Manufacturers recommend using high-temperature washing as rarely as possible, especially not running several cycles in a row with water heating to 60-90°C. It is advisable to allow the equipment to cool down before the next start. The power of the heating elements installed on Whirlpool washing machines is 1800-2200 W. This value corresponds to the energy consumption of any other heaters.

"Heart" of the machine

The drum in which things are washed is spun using a motor. The motor, through a drive mechanism, accelerates the “centrifuge” to the required speed. Automatic washing machines Whirlpools are equipped with commutator electric motors.

Collectors are cheaper than inverter motors, but they are inferior to them in reliability. The maintenance-free service life of inverters is much longer, and they are less sensitive to voltage drops and do not require periodic maintenance. But their cost is much higher.

Commutator motors react quite sharply to surges in the electrical network, so it is advisable to connect them through a stabilizer.

Another drawback of collectors is the need for periodic maintenance, namely, replacement of electric brushes. After approximately 3-5 years of operation, the carbon rods wear off and have to be reinstalled. Changing brushes is not difficult - you can do the job yourself, at home.

The engine is considered the “heart” of an automatic machine. It starts working immediately after starting the desired washing program. Depending on the mode activated by the user, the control module controls the speed of the electric motor, constantly either slowing down its rotation speed or accelerating it to the maximum.

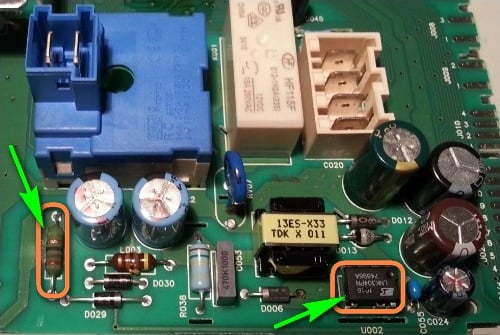

The "brain" of the washing machine

The main control module controls the operation of the washing machine. The user, through the dashboard, tells the “brain” all his wishes regarding the upcoming wash: the desired mode, additional options, the required heating temperature, the need for a spin, etc.

The control board of the Whirlpool washing machine consists of semiconductor elements: triacs, triggers, resistors, capacitors, thyristors, and a controller.

Each node of the automatic machine has its own section on the board. Some semiconductors regulate the operation of the drain system, others monitor the intake valves, and others monitor the engine.

So, having detected problems in any part of the circuit or lack of communication, the automatic machine notifies the user of the problem by displaying an error code on the display. Washing machines without a screen indicate a malfunction by flashing the display on the dashboard. Thanks to self-diagnosis, it is easier for the owner to identify the cause of equipment malfunctions. It is the “intelligence” of the washing machine that sets the sequence of execution of each washing program. All valid algorithms are “written” in the firmware. The user can only tell the module through the dashboard which mode is needed.

There is nothing super-complicated in the design of front-facing machines. Knowing where everything is located and which part is responsible for which functions, you can independently diagnose the equipment and carry out minor repairs without overpaying the technicians.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment