How does an LG washing machine work?

If, with a properly functioning washing machine, the owner does not need to know the structure of the LG washing machine, then if it breaks down, the interest increases significantly. To perform even a simple replacement of a hose or pressure switch, you need to know the basics of the washing machine: what is unscrewed and how. You can figure out the insides of the equipment yourself if you take the time and carefully read our publication.

If, with a properly functioning washing machine, the owner does not need to know the structure of the LG washing machine, then if it breaks down, the interest increases significantly. To perform even a simple replacement of a hose or pressure switch, you need to know the basics of the washing machine: what is unscrewed and how. You can figure out the insides of the equipment yourself if you take the time and carefully read our publication.

External design of the machine

Knowing how an LG machine works, you don’t have to worry about a possible breakdown and fix the situation without involving service technicians. This will save time and money, and will improve your practical skills. But for a successful result, you need to get to know the machine well, both outside and inside.

The factory instructions will help you study the device of a specific LG model in detail.

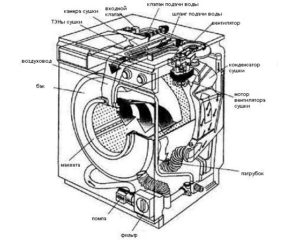

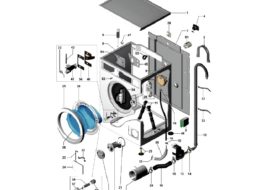

Like other washing machines, LG machines have a casing. It consists of a front and back panel, a top cover and a base-bottom. A considerable area of the front wall is occupied by a hatch designed for loading laundry into the drum. Depending on the location of the door, models are called frontal when the opening is in the front, and vertical when on top.

The main external elements of washing equipment also include a dashboard with a program switch, buttons and a display. Here, but to the left, there is a retractable tray for detergents, popularly simply called a powder receptacle. In the lower right part of the body there is a technical hatch, behind which a garbage filter and an emergency drain hose are “hidden”.

On the other side of the case you can see two hoses and a power cord with a plug.The latter is plugged into the outlet in the traditional way and supplies current to the washing machine. There are two rubber tubes: one comes out at the top and is called the filler tube, and the second, the drain, is attached to the volute through the bottom and comes out from the bottom. This completes the external review, and we can begin our acquaintance from the inside.

Internal organization

If you look inside the machine, you will see dozens of various parts, meters of wiring, as well as many fasteners and rubber gaskets. While some elements of the system, such as counterweights, are simple, others, such as the control board or pressure switch, are very fragile and complex mechanisms. We invite you to get to know each of them.

- Control board and other electronics. This is the “brain” of the washing machine, which controls all elements of the system. Thus, the module starts the washing machine when current flows through the cord, fixes the program selected by the user, controls the filling of the tank, monitors the engine speed and performs other related tasks. Each element on the electronic unit, called a resistor or triac, is responsible for a specific part and allows you to fully coordinate the operation of the machine. If the “helpers” stop receiving signals from their “wards”, then a failure occurs in the circuit and the unit stops.

The control board is the most fragile and expensive part in a washing machine.

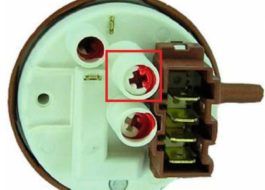

- Level sensor. Also called a pressure switch and controls the degree of filling of the tank. It consists of a round “box” and a long transparent tube going down. Due to the latter, the pressure in the tank is measured, after which the information is transmitted to the board. As soon as a certain water level is reached, the module gives a command to stop the intake.

- Inlet valve. It is a plastic “box” with one or more coils. When voltage is applied to the coil, the membrane opens and water begins to flow into the tank. And vice versa, as soon as there is enough liquid in the machine, the board again acts on the membrane, the mechanism is activated, and the flow stops.

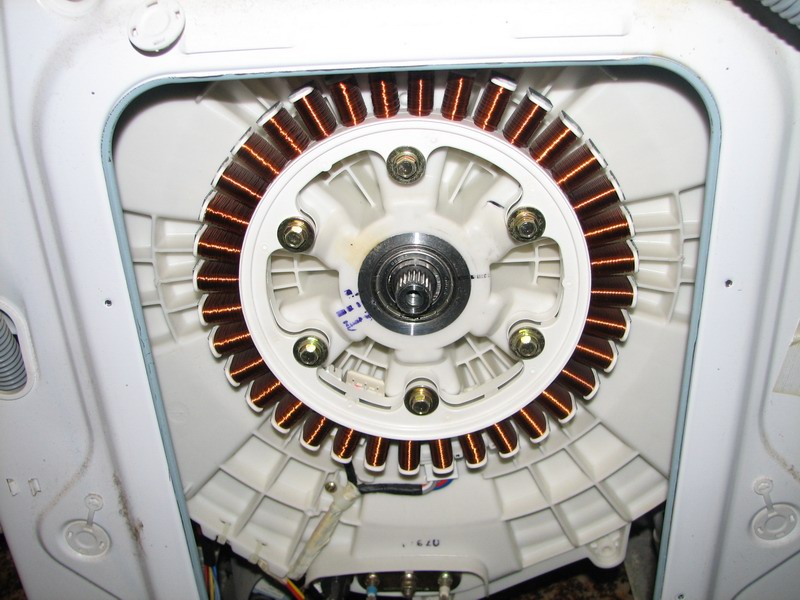

- Engine. One of the most important elements of the machine. In old-style machines it is a commutator type and must be supplemented with a pulley and a drive belt. The latter, due to its rubber structure, is considered the “weak link” of the unit, as it often stretches, flies off and breaks. Therefore, modern washing machines are equipped with an inverter motor with direct drive. The design of this engine is devoid of a belt drive and other “intermediaries”, since the part is installed directly on the drum. Due to this, the service life increases to 10 years with a warranty from the manufacturer.

- Heating element or electric heater. The name speaks for itself - the device heats the water in the tank to a specified level depending on the selected program. As a rule, the value is set by the board, after which the heating element starts working.

- Temperature sensor. Modern LG models, like other well-known brands, allow washing in different modes from 30 to 90 degrees. This involves installing a thermistor - a metal tube placed inside the heater. The sensor records the degree of water heating, informing the control module. When the required temperature is reached, the system turns off the heating element.

- Hatch locking device. In simple words, it is an electronic door lock. First, the user closes the lock manually, and with a click, the UBL also turns on. Only after this the water intake starts.

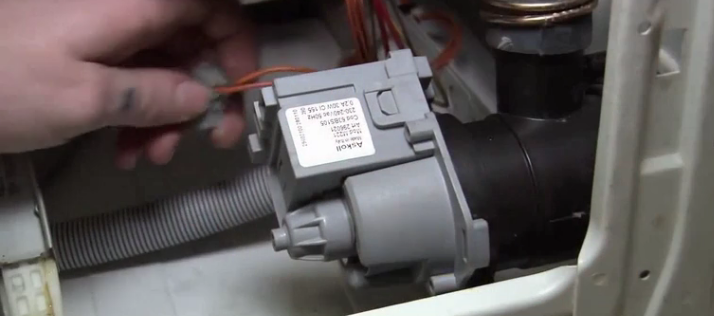

- Pump.The pump is often called the “heart” of the washing machine, since it is it that pumps water out of the tank. Depending on the type of device, drainage can be synchronous or asynchronous, collapsible or non-dismountable. Consists of a motor and a rotating impeller. A volute is installed on top of the pump, through which pipes and a drain hose are connected to the system. Despite the remote location, the part often becomes clogged due to the carelessness of the owners of the machine. Thus, coins left in pockets can get through the garbage filter to the pump and block its operation.

- Depreciation. To prevent the machine from jumping all over the room during the spin cycle, the device is equipped with dampers - spring struts that dampen vibrations and oscillations. Shock absorbers are attached on one side to the bottom of the tank, and on the other to the base of the body.

- Springs. The upper spring system also dampens the “jumps” of the machine. The springs are attached at one end to the tank, and at the other to the sides of the washer.

- Counterweights. The balance of the body is maintained by heavy concrete or plastic blocks. They are fixed with bolts on top of the tank and smooth out vibrations emanating from the unit. But even a solid structure can collapse over time. Particularly affected are fasteners, which are recommended to be tightened periodically.

- Drum. Cylindrical container made of stainless steel. The front part of the drum is open for loading laundry, and the cross and shaft are located at the back. Draining of water becomes possible due to the many “holes” on the surface of the tank.

- Tray for detergents. The powder receptacle should be considered in more detail. This is a plastic dispensary consisting of three compartments: the first is filled with powder for the main wash, and the second, smaller one, is for the preliminary wash. The “*” symbol or the image of a flower marks the air conditioner compartment. There is a tray in the hopper through which the pipes from the inlet valve are connected to fill the water.

- Cuff. A rubber seal that encircles the hole in the hatch and is responsible for the tightness of the drum. The seal is pulled over the tank and body, and secured with clamps for reliability.

- Hoses and pipes. Through them, water enters and drains from the machine, passing through the main elements of the washing machine. So, first, through the inlet hose, the flow from the water supply goes into the tray and tank, and then with the help of the drain hose it goes into the sewer.

If you wish, it is not difficult to understand the structure of the washing machine. The article will introduce you to the main elements of the system, and the instructions will contain all the auxiliary diagrams.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment