How does a Kandy washing machine work?

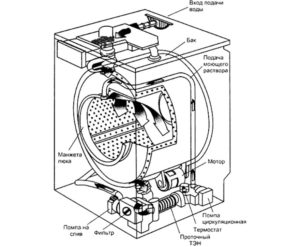

Before you try to repair a washing machine at home and “climb” inside the machine yourself, you need to understand how the machine works. It is important to understand where the main components and sensors are located, how the parts are connected to each other, and what functions they are responsible for. This is the only way to properly repair equipment without harming it.

Before you try to repair a washing machine at home and “climb” inside the machine yourself, you need to understand how the machine works. It is important to understand where the main components and sensors are located, how the parts are connected to each other, and what functions they are responsible for. This is the only way to properly repair equipment without harming it.

How many parts are inside the machine?

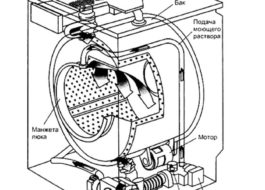

The design of modern washing machines is quite simple. If you delve into the structure of the washing machine Candy, then by analogy it will be clear how machines of other brands work. Any model has:

- engine. Kandy are equipped with commutator motors; machines of other brands have inverter motors;

- tank-drum assembly;

- drain pump;

- control panel with main electronic module;

- shock-absorbing elements;

- bearing unit;

- metal case;

- inlet valve;

- heating element;

- temperature sensor;

- pressure switch;

- garbage filter;

- dispenser;

- hatch blocking device;

- drum cuff.

This is a basic set of elements provided for in the design of any washing machine. Having understood the structure of the Candy washing machine, you can calmly analyze the behavior of your “home assistant”. It will immediately become clear what could be the cause of this or that malfunction, and what parts should be checked first.

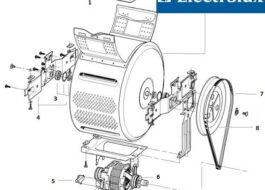

How does the drive mechanism work?

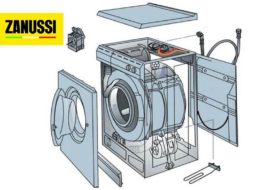

The Candy washing machine is equipped with a plastic tank with a built-in drum. To prevent deformation of the container, it is not very rigidly attached to the body. This avoids strong vibrations that destroy the tank.

During the washing process, and especially the spin cycle, the tank actively moves, but the metal body of the machine remains motionless. This guarantees the safety of the tank. The main plastic container of the washer is supported by a pair of shock absorbers at the bottom and several springs at the top.

Rotation of the drum of Kandy washing machines is made possible thanks to the belt drive mechanism. Vending machines have two pulleys: a large one, which is attached to the drum, and a small one, located on the motor.

The pulleys are united by a common belt. After starting the wash, the electric motor sends revolutions to the drum through a belt drive. Due to this, the “centrifuge” begins to rotate along with the things loaded into it.

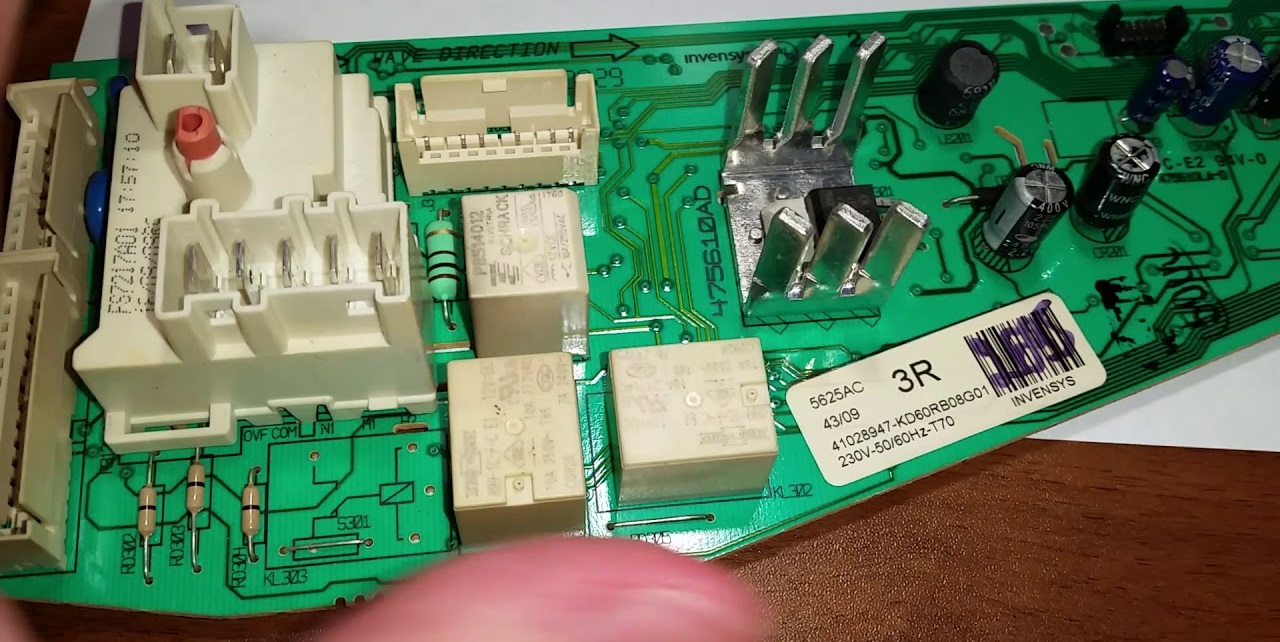

The “brain” of the washing machine is the control module.

The board monitors the execution of the process, receives signals from the machine parts and, in turn, gives commands. For example, the block controls the water supply to equipment as follows:

- opens the inlet valve to draw liquid into the tank;

- “orders” the heating element to heat the water to the required temperature;

- activates the pump when it is necessary to drain the wastewater.

Now you have a general idea of the main components of the Kandy washing machine and the role they play. To achieve specifics, it is better to analyze the operating principle of each element separately.

Drum quality

Washing machine models differ in the materials used to produce components. Washing machines with a stainless steel tank are considered more reliable and wear-resistant. Such equipment will last longer than those equipped with a plastic tank. The drum is always made of stainless steel.

All washing machines produced under the Candy brand are equipped with a non-separable plastic tank.

So, the tank is the main capacity of any automatic machine. Can be made of durable plastic or stainless steel. It has a drum built into it, into which clothes are loaded for washing.

The surface of the drum is “strewn” with a large number of holes. It is through them that water from the tank is “poured” into the “centrifuge”. Also inside the metal tank there are several plastic “combs” that can improve the quality of washing.

The automatic machine first draws water into the tank. There the liquid is mixed with powder or gel and then enters the drum. It is important that no foreign objects get into the tank, otherwise this can lead to leaks and other troubles. Therefore, carefully check the pockets of your clothes before loading them into the machine, and wash your underwear and socks in special bags.

How is water heated?

The water entering the tank is heated by a heating element. The tubular element is built into the bottom of the washer. The main problem with heaters is that they become covered with a thick layer of scale, after which their thermal conductivity is impaired.

If your region has hard tap water, it is better not to save money and install a softener filter at the entrance to the apartment or directly in front of the inlet hose of the machine. Due to this, it will be possible to protect the “insides” of the machine from scale.

The more often you start high-temperature washing, the faster the heating element will fail. Therefore, there is no need to constantly “rinse” things in hot water heated to 60°C-90°C. This will not be useful for either clothing or equipment.

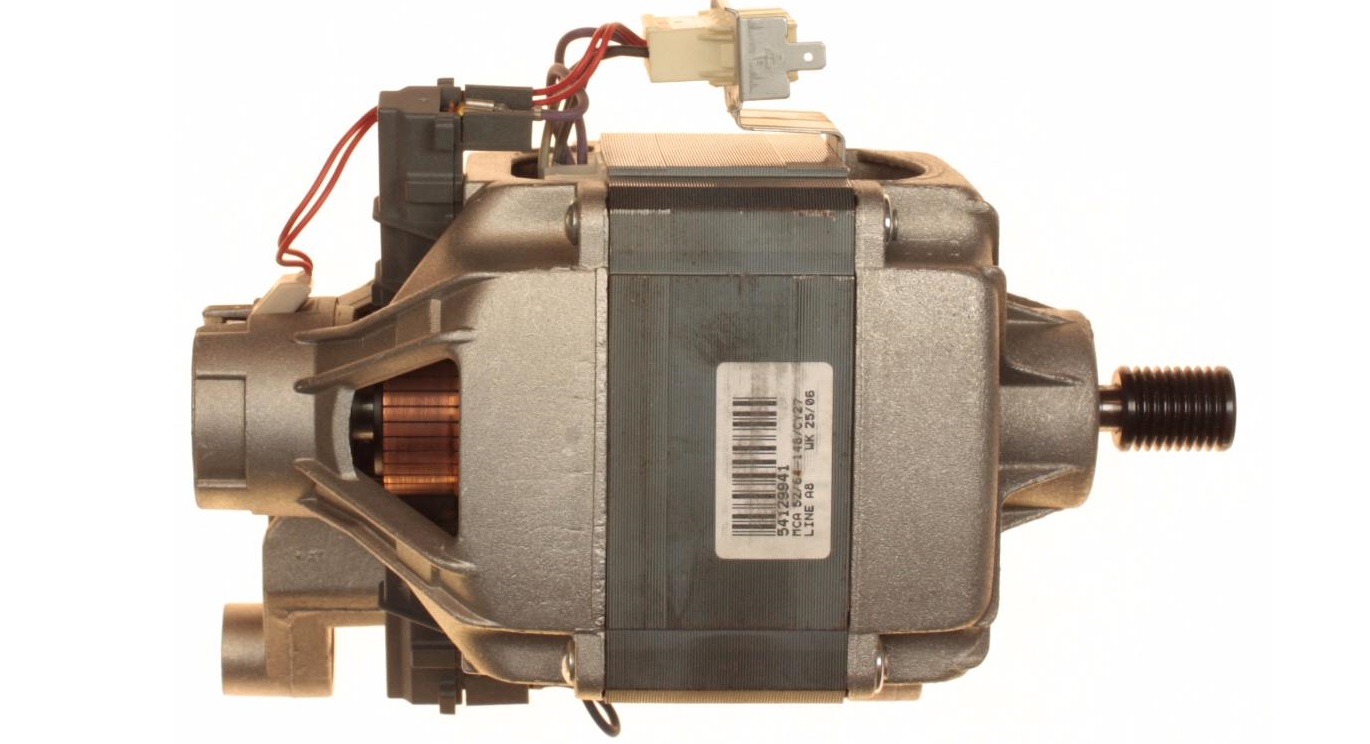

Electric motor

The connection between the drum, pulley and motor has already been discussed. Kandy automatic machines are equipped with commutator motors. This type of engine is used by the manufacturer to save money, to reduce the cost of equipment as much as possible and make it more accessible to customers.

Unfortunately, collector engines are not reliable. They do not tolerate power surges well, so Candy washing machines should be connected through a stabilizer. Such motors require special treatment. For example, you must remember to change the motor brushes in a timely manner to maintain its performance.

Pumping water

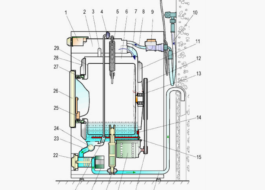

Several elements are responsible for supplying water to the washing machine. These are the control module, inlet valve, inlet hose and level sensor. Filling the tank is carried out according to the following scheme:

- the “brain” of the washer gives a command, after which the inlet valve opens;

- water begins to flow into the system;

- a pressure switch monitors the liquid level in the tank;

- when the container is filled to the required “mark”, the sensor signals this to the board, and the “brain” closes the inlet valve;

- water stops “entering” the tank.

Next, the control module turns on the heating element, which will heat the water to the desired temperature. Draining of the waste liquid begins after the “brain” transmits a signal to the pump. The pump, having received a command, pushes the wastewater through the drain hose into the sewer. These processes are repeated several times - during the main wash and rinse. Water is collected, the laundry is “rinsed” in it, and then, due to the well-coordinated work of the units, the liquid is removed from the machine.

Electronic filling

The main electronic unit of the automatic machine is responsible for all components, not counting the control panel (it is connected to a separate board). These devices are the “intelligence” of technology.They are the ones who “distribute” commands to all sensors and system elements, ensuring uninterrupted operation of the equipment.

Washing programs and various additional options are algorithms recorded on the control board. Therefore, the module is responsible for executing the mode that is launched by the user. The electronic unit includes various parts: triacs, microcircuits, transistors, thyristors and others. Contact between elements is achieved through special tracks.

The control panel serves as a kind of informant that “tells” the machine’s intelligence what the user currently wants. Its main task is to inform the electronic module about all the details of the upcoming wash (data about the selected program, temperature mode, number of spin revolutions, connection of additional functions to the main cycle).

Kandy washing machines equipped with a display notify the user about the washing details. The screen displays the remaining program execution time and cycle stages.

Other details

In addition to the main components, the washing machine is packed with many additional elements. In an automatic machine, everything is interconnected, so even without “minor” parts, washing cannot begin. What components do you mean?

- Springs and shock absorbers. These are important elements that reduce vibration, thereby preventing damage to the tank.

- Hatch cuff. The rubber seal serves to seal the door. Due to this, water does not pour out of the drum.

- Hatch blocker. UBL ensures that the door closes “tightly” and does not swing open during washing.

- Drive belt. This is the same rubber band that spins the pulley, and the “wheel” already rotates the drum. Therefore, the operation of the machine is impossible without this mechanism.

- Drain filter. It protects the pump from various debris. Foreign objects, paper, hair, threads and lint settle on the element without entering the pump.

- Counterweights. These are large and heavy blocks that are placed inside the body to make the machine heavier. Due to these “stones,” the washing machine resists the centrifugal force that appears when the drum rotates at high speeds. Without them, the equipment would constantly “jump” around the room, feeling the pressure of the tank on the side panels.

- Drum hatch. The role of this detail is obvious - without the door, washing would simply be impossible.

- Drawer for detergents. Powder, conditioner-rinse aid, and stain remover are added to the container. The compositions are dosed into the tank throughout the cycle. Typically the tray is divided into three sections.

- Pipes. They are built inside the machine. This is a kind of “circulatory system” of the washing machine. Water moves along them inside the machine. Through the inlet valve into the tank, from there to the pump.

- Inlet and drain hoses. Everything is obvious here - one way the water enters the machine, the other flows into the sewer.

Knowing what parts the washing machine consists of, which unit is responsible for what, you can analyze the behavior of the equipment and identify the cause of problems in the operation of the machine.

If a malfunction occurs, you will be able to understand what is causing it. What components and components should you pay attention to? For example, if water does not leave the tank, it will be clear that the elements of the drainage system need to be checked. When the drum rotates with a strong knocking, rattling and grinding noise, you will determine that the problem is clearly in the bearing assembly.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment