How does the Atlant washing machine work?

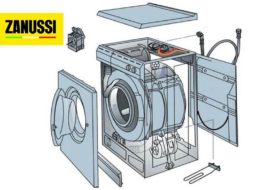

Front-loading washing machines are designed according to the same principle. Of course, there may be differences in the form of a reloading door, a second drum, the presence or absence of a display, or a service hatch, but the “filling” of the machine remains the same. As an example, let’s analyze the structure of the Atlant washing machine to understand what main components and components are used when assembling the front-facing units.

Front-loading washing machines are designed according to the same principle. Of course, there may be differences in the form of a reloading door, a second drum, the presence or absence of a display, or a service hatch, but the “filling” of the machine remains the same. As an example, let’s analyze the structure of the Atlant washing machine to understand what main components and components are used when assembling the front-facing units.

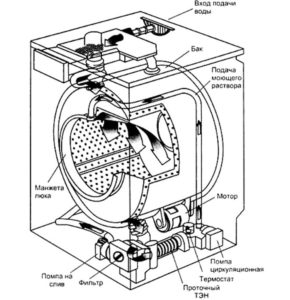

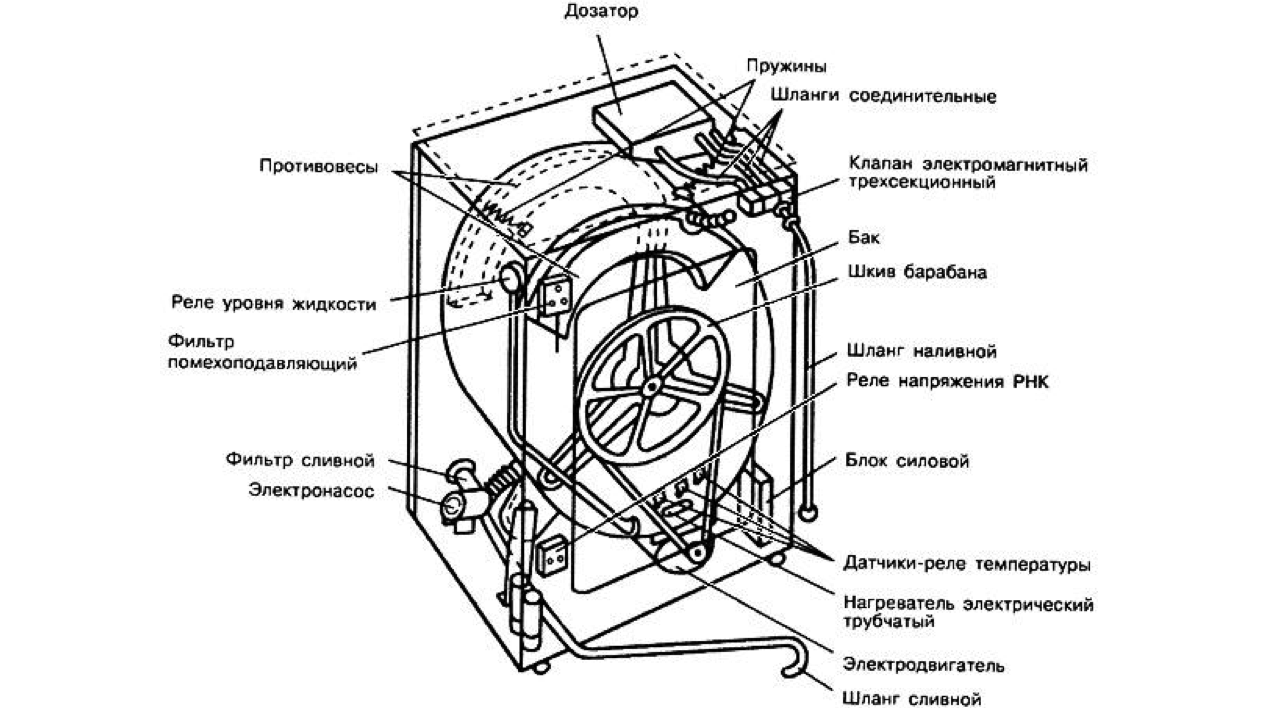

Main elements

It is not difficult to understand how a washing machine works. All components are listed in the factory instructions, and a wiring diagram for connecting the components to the components is also shown there. You can highlight the main components of the machine and additional parts.

Basic elements include:

- electric motor;

- tank (can be made of plastic or metal);

- drum;

- drain pump;

- control module;

- shock absorbers, dampers, springs (necessary to suppress vibrations during machine operation);

- bearing unit;

- a heating element;

- filling solenoid valve;

- frame;

- pressure switch

Having understood the structure of the Atlant washing machine, you can diagnose breakdowns and repair the equipment yourself, without turning to specialists.

This is the main set of components; without them, the Atlant washing machine will not be able to function. Knowing where each of the elements is located and understanding what it is responsible for, it is easier to notice improper operation of the machine and repair the equipment in a timely manner.

Features of the machine

In a normal situation, all components and sensors of the washing machine work smoothly, without failures. Each element strictly performs its assigned functions. The process is controlled by the main control module, the “brain” of the machine.The board monitors the order of operations, receives and transmits signals, and ensures communication between components.

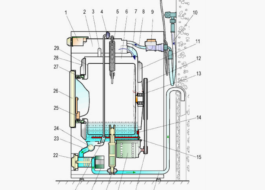

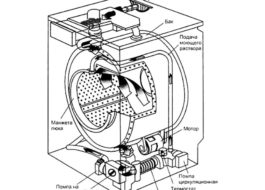

The most voluminous element of the washing machine is the tank. It is a large plastic or metal cylinder, the position of which is controlled by shock-absorbing springs and dampers. A drum made of stainless steel is placed in the container. It actively rotates during washing, thanks to the “wheel” attached through the cross. The pulley is spun by the drive belt, which in turn is driven by the engine. It is due to the increased speed that the laundry in the drum is washed.

Almost all automatic machines from the Belarusian manufacturer are equipped with plastic collapsible tanks.

After starting the wash, the drum begins to fill with water. The user, by pressing the “Start” button, sends a signal to the control board, which gives a command to the solenoid valve. It opens, liquid flows into the system, and the pressure switch controls the degree of filling of the tank. When the water reaches the desired level, the sensor will notify the “brain” about this, and the set will stop.

Next, the heating element is activated to heat the water to the set temperature. The control unit controls the stages of the cycle, moving from soaking to main wash, then to rinsing. In between, a command is given to the pump to drain the water.

This is exactly the general picture of almost every wash. In fact, there is nothing complicated in the principle of how the machine works. To understand even better how the machine works, you need to disassemble each of its components separately.

How does the main node function?

The tank is the largest element of the SMA. At Atlant it is made of plastic, which explains the low cost of the equipment.Some manufacturers make containers from stainless steel; such equipment costs an order of magnitude more, but is considered more reliable. The tank in the body is located horizontally, but you can find models with a tank located at an angle.

A metal drum is built into the main tank, where laundry is placed for washing. The water is heated and mixed with the powder in the tank, then it penetrates through the pores on the walls of the drum to the clothes. The ribs present on the drum surface improve the quality of washing and help cope with dirt.

Very rarely, the “tank-drum” assembly is damaged in Atlant washing machines. This can happen if you do not comply with the amount of things allowed for loading, or if you do not install the machine at the level. Foreign objects can also pierce the plastic tank, for example, a bra wire, a nail, a hairpin, or a key that got inside the washing machine due to the user’s carelessness.

How is water heated?

The water “reaches” the desired temperature thanks to the heating element. The heating element is located directly under the drum, on the back side of the housing. You can access the tubular heater by removing the wall and removing the drive belt.

The heating element is one of the most frequently damaged and replacement elements of Atlant washing machines.

The heater breaks down because:

- constantly comes into contact with hard water, as a result of which scale forms on its surface;

- the settled layer of limescale interferes with the heat transfer of the heating element, which leads to overheating and burnout of the element.

Therefore, it is better to avoid constantly using high-temperature washing modes. Especially, run several cycles in a row with water heating to 60-90 degrees.The heating element should be allowed to cool for an hour, and only then turn on a new program. If we talk about the power of the heater, it consumes approximately 1800-2200 Watts. These values are identical to those of other heating devices.

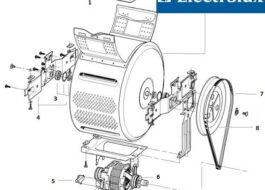

What makes the drum move?

The drum spins to the specified speed thanks to the washing machine motor. The engine, through a drive belt and pulley, accelerates the tank to the desired speed, ensuring high-quality washing and spinning. The maintenance-free service life of an engine depends on several parameters, primarily on its type. Inverter motors are more reliable and durable than commutator motors.

Atlant brand washing machines have collectors - they are cheaper than inverters, but at the same time they are inferior to the latter in several characteristics. Commutator motors are too sensitive to voltage surges and require regular maintenance, for example, replacing brushes when they wear out. You can take this feature into account and connect the automatic machine through a stabilizer - then you won’t have to worry about changes in the power supply. As for electric brushes, this is a simple repair that takes a little time.

Water is poured into the drum according to the following principle:

- the user starts the wash by pressing the “Start” button;

- the module commands the solenoid valve to open;

- the pressure in the system decreases, water begins to flow into the tank;

- the pressure switch measures the amount of liquid;

- the level sensor sends a signal to the board that the tank is full;

- the block, based on the information received, “orders” the intake valve to close;

- The water supply to the machine is completed.

After this, the machine starts heating the water and the main wash. When the water needs to be drained, the module signals this to the pump.The pump begins to pump out water and discharge it through the pipes into the sewer. The level sensor, noticing that the tank is empty, notifies the control unit. When the washing is completed, the “brain” stops the drainage system, makes sure that all elements of the machine have finished working, and turns off the hatch lock.

"Brain" of the machine

Continuous communication of all components with each other is possible thanks to electronics. The control module is the “brain” of the washing machine, coordinating the actions of all nodes, issuing commands and monitoring their implementation. The board consists of numerous semiconductor components. Communication with other parts of the machine is carried out along electrically conductive paths.

Modern washing machines are equipped with a self-diagnosis system. It notices any failures and malfunctions in the operation of the equipment and notifies the user about them by flashing the display or displaying an error code on the screen.

It is the “brain” of the unit that sets the algorithm of actions when choosing a specific washing program. The sequence of operations and settings of each mode are programmed in the intellect, the user only has to launch the desired one through the control panel. Some Atlant models offer the possibility of adjusting factory washing programs. So, the user can change the temperature of water heating and the spin speed.

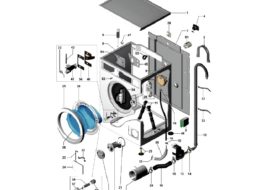

Other “filling” of the washing machine

To fully understand how a front-facing washing machine works, you will have to understand not only the main components and sensors, but also additional elements. Although we consider these details as secondary, in fact, without them the machine will not be able to perform its functions. Any, even the smallest element plays an important role in the design of the device.

So, we are talking about the following components:

- door cuff. The sealing rubber ensures the tightness of the system;

- locking device. It is activated by the “brain” after mechanically closing the hatch and starting the wash. When the UBL has triggered, it will be impossible to simply open the door until the end of the cycle;

The control module automatically activates the UBL after starting the washing mode.

- drive belt. It is he who transmits the impulse from the engine to the drum pulley, after which it spins the container to the required speed. If the elastic band breaks or slips, the wash will stop and the drum will “freeze” in place;

- counterweights. These are concrete blocks necessary to give the machine stability. Without them, the washing machine will not be able to withstand the centrifugal force that occurs when the drum moves;

- garbage filter. Protects the drain pump by preventing debris, hair, threads, and foreign objects from entering it. Needs periodic cleaning;

- door. No explanation is needed here. Without a hatch, putting things into the machine would be problematic;

- powder receptacle. The dispenser is divided into sections, each of which is loaded with a specific product - for preliminary or main washing, rinsing. The cuvette helps the ingredients enter the tank gradually, thereby achieving maximum washing effect;

- pipes Elements connecting the main components of washing machines. For example, the drain pipe is located between the main container and the pump, other hoses lead from the dispenser to the tank. Thanks to them, water circulates freely in the system.

Having understood how the Atlant washing machine works, you can independently analyze the operation of the equipment and notice the first “symptoms” of breakdowns. It is important to read the factory instructions to understand the design of the “home assistant” and promptly fix minor problems.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment