How does a washing machine drain pump work?

It is the drainage system of the washing machine that is responsible for the timely emptying of the tank. At a certain moment, the pump starts and pumps out the waste liquid into the sewer. If problems arise with the pump or drainage in general, the washing machine will stop working - the drum will be full and blocked. It is easier to avoid or correct stagnation if you know the structure of the washing machine drain pump. Let's consider the design of the pump, the main components, the principle of its operation, types and nuances of operation.

It is the drainage system of the washing machine that is responsible for the timely emptying of the tank. At a certain moment, the pump starts and pumps out the waste liquid into the sewer. If problems arise with the pump or drainage in general, the washing machine will stop working - the drum will be full and blocked. It is easier to avoid or correct stagnation if you know the structure of the washing machine drain pump. Let's consider the design of the pump, the main components, the principle of its operation, types and nuances of operation.

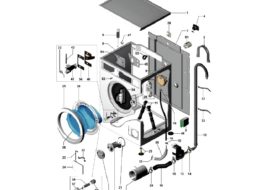

Drain pump parts

Knowing how the pump works can significantly extend its service life and make repairs easier. The latter usually involves replacing the pump, which will necessarily require selecting an analogue. In order not to make a mistake with a new device, you need to take into account several important nuances: power, type of mounting and terminal diagram.

Modern automatic and semi-automatic machines are equipped with drain pumps with the following operational parameters:

- rated power – from 25 to 40 W;

- type of fixation on the cochlea - with a screw or latches;

- contact diagram - paired or separate terminals;

- type of pump - simple or circulation.

Pumps also differ in the filtration system they provide. Spiral filters are often used, which “hold” water in the pump when clogged. As a result, the dirty liquid stagnates and begins to smell unpleasant. You will have to check the nozzle, unscrew it and clean it of accumulated debris and scale.

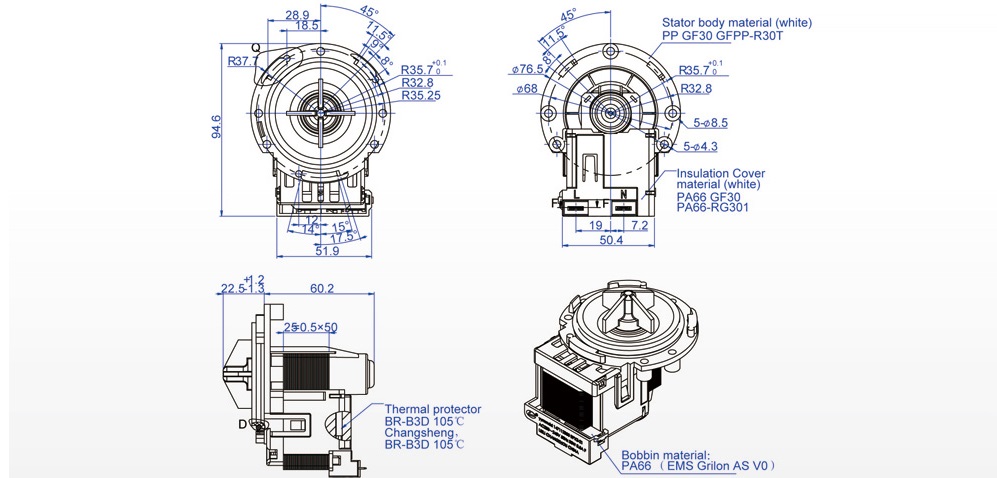

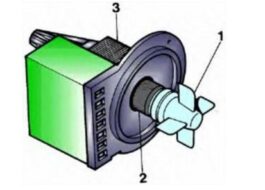

The drain pump consists of a housing, a rotor, an impeller, a magnetic core and insulating windings.

As for the design of the pump, it consists of the following elements:

- plastic casing;

- rotor;

- impeller;

- magnetic core;

- winding.

The mechanism operates like an asynchronous motor, representing the interaction of moving and stationary elements. The system starts after the appropriate command from the control board: the module gives a signal, and the rotor - a permanent cylindrical magnet - begins to rotate. Then the impeller, located on the shaft at an angle of 180 degrees, unwinds. The blades move slowly, giving the water the desired direction. The magnetic core and two interconnected insulating windings remain static, maintaining the functioning of the system.

This is how a simple pump starts in a washing machine. Due to its elementary design, it breaks rarely and for easily removable reasons. More often, the impeller impeller falls off, causing the pump to run “idle.” Sometimes a blockage is to blame for the failure; extremely rarely, the core magnet weakens.

A circular pump differs in that it passes fluid only in one direction - to the “outlet”. The tightness of the device is achieved through an improved design. Thus, on Samsung washing machines, the pump is equipped with a sealing collar that covers the fitting and prevents water from entering the bearing assembly.

Modern pumps are also equipped with a rotor shaft passing through a central rubber bushing with a crimp - a spring ring. The structure is first generously lubricated with moisture-resistant lubricant. Due to the thick layer of sealant, all gaps are “closed”, which ensures smooth rotation of the mechanism, extending the service life of the pump.

How to find a pump and how does it work?

The pump is activated for every wash, otherwise the machine would remain standing with a full tank of water.But the pump does not “turn on” immediately, but at the final stages of the cycle. To understand the principle of operation of the drainage device, you will have to follow the entire “washing” process.

The washing machine starts working by turning on the power, selecting the appropriate mode, setting the remaining settings and pressing the “Start/Start” button. The control board receives the signal and starts the system:

- the solenoid valve opens;

- water from the water supply under pressure enters the machine;

- the pressure switch measures the specified amount of water, controlling the filling;

- water “passes” through the pipes and enters the powder receptacle, where it is mixed with detergent;

- soapy water is already poured through the main pipe into the tank;

- The laundry loaded into the drum is immersed in a soap solution;

- The machine starts to wash.

The pump is “turned on” in the process at the final stages of washing - rinsing, spinning and draining. With its help, waste water is pumped out of the tank, completely or in portions. The pump only stops working when soaking. The control board activates the drainage system - the module gives a command to drain water from the tank. Pumping liquid into the sewer occurs as follows:

- the pump turns on, the impeller spins up;

- water leaves the tank through the hose connecting the tank to the pump;

- the liquid “flows” through the hose through the garbage filter, where large debris, some lint and hair are retained;

- water enters the pump and passes through it;

- the liquid is discharged through the drain hose into the central sewer system;

- the pressure switch monitors the emptying of the tank;

- as soon as the tank becomes empty, the board gives the pump a signal to turn off.

For unhindered drainage, the water is located in the lower part of the housing.It is important that the drain hose is fixed according to the instructions - above the level of the washing tank, otherwise the machine will empty itself by gravity or pick up sewage from the sewer.

According to the instructions, the drain hose must be raised 60-80 cm from the floor, otherwise the water will leave the tank by gravity.

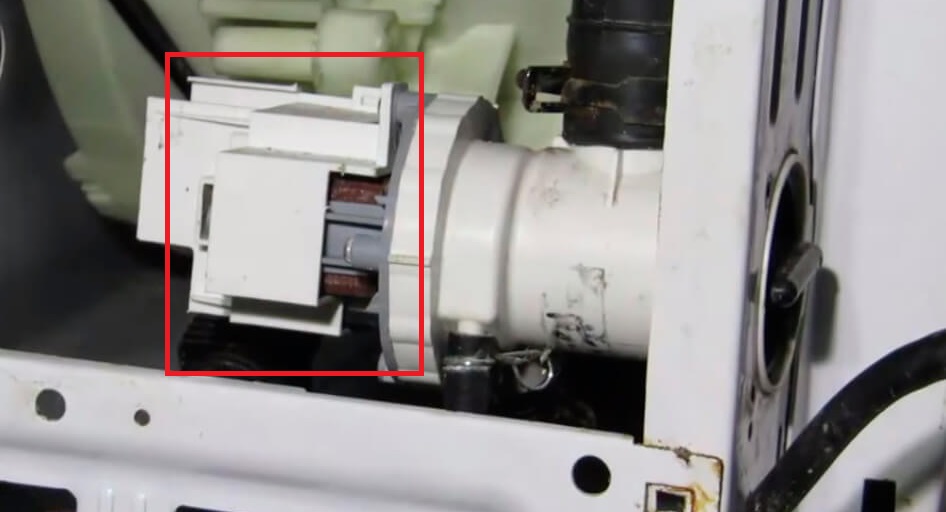

The electric pump, like the entire drainage system, is located below, under the washing tub. The pump is fixed to the plastic volute with 2-4 screws. Getting to the device is easy: just put the washer on its side, disconnect the tray and look under the bottom.

What are the specified details?

Drain pumps mainly vary in power and type. There are two of the latter: circulating and simple. Let's look at each type in more detail.

- Standard pumps are installed on most machines from the budget segment. Their task is simply to pump out dirty water from the drum.

- Premium segment washing machines are equipped with circulation pumps. Such devices are paired with simple pumps, differing in the supply of water directly to the washing zone with its subsequent circulation through the system. This improves the quality of washing and extends the service life of the equipment.

Collapsible pumps are rare; more often their bodies are solid, which excludes their repair. If the pump breaks down, it is not repaired, but replaced with a new one. By the way, the cost of the device is low if we are talking about the “simple” type. Before replacing the pump, you must ensure that it is faulty. Often there is no breakdown as such, but a banal and easily removable blockage is to blame for the failure. In this case, it is recommended to first diagnose the drainage: turn off the power to the machine, clean the garbage filter, get to the pump, inspect the impeller, and then test the contacts with a multimeter.If a deviation from the norm is detected, we dismantle the old one and install a new device.

Pump prevention

Without a pump, the machine will not wash. It is considered a key component and rarely needs repairs - manufacturers often promise an accident-free period of 8-10 years. But the “maximum speed” is not always achieved, since the performance of the device is affected not only by the quality of the components, but also by the operating conditions of the washing machine. If the equipment is used carelessly and is not maintained in a certain way, then problems with drainage arise within 2-3 years.

The main cause of failures is blockages. Lime and soap deposits, hair and threads, foreign objects and debris fall into the drainage, clogging the pipes, the filter and the pump itself. To prevent such a problem, you must follow a few simple rules:

- organize a tap water filtration system;

- Shake the laundry loaded into the drum and check for forgotten items;

- wash heavily soiled items by hand first;

- assess water hardness and, if it is high, use softeners;

- choose quality detergents;

- periodically unscrew the garbage filter and clean it from accumulated dirt;

- clean the washing machine every six months;

- Always monitor the emptying of the drum (listen, monitor the presence of water in the tank).

The drainage system, and the pump in particular, must be constantly monitored. Otherwise, there is a risk of missing “alarm bells” and leading to a “fatal” problem. If at the start the breakdown is eliminated with a cheap replacement, then at the end you will need to buy a new washing machine.

The pump cannot be repaired - only replaced.

You can suspect problems with drainage based on obvious “symptoms”: slow drainage, wet laundry in the tank, a corresponding error on the display, or an uncharacteristic hum of the pump when switching to spinning. In this case, it is better not to postpone the check until later, but to immediately diagnose the system. Ideally, contact a service center for professional help.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment