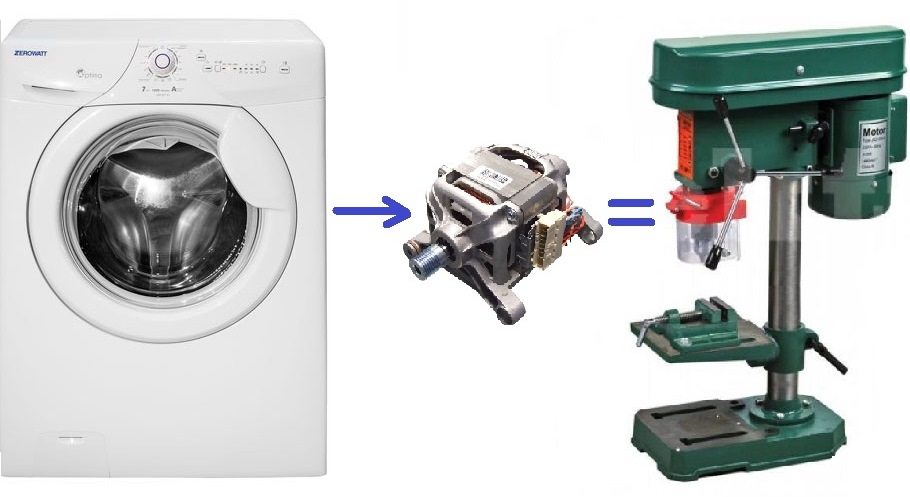

Wood lathe from a washing machine engine

Are you thinking about recycling your old washing machine? Do not rush to throw away the machine; most parts of the washing machine can be given a new life. For example, you can make many interesting devices from the electric motor of a faulty “home assistant”. Let's talk about how to build a wood lathe from a washing machine engine, what this requires, and we'll tell you about the progress of the work.

Are you thinking about recycling your old washing machine? Do not rush to throw away the machine; most parts of the washing machine can be given a new life. For example, you can make many interesting devices from the electric motor of a faulty “home assistant”. Let's talk about how to build a wood lathe from a washing machine engine, what this requires, and we'll tell you about the progress of the work.

What is needed to make a machine?

It is not difficult to assemble the structure with your own hands. You can make the simplest model of the machine, consisting of a motor, a tool rest and a tailstock (bed). To make a lathe for wood processing you need to prepare:

- working engine from an old washing machine;

- a board that will serve as a base for the device (alternatively, the machine can be attached directly to the desktop);

- a metal corner measuring 20*20, 195 mm long and a square pipe (will be used to prepare the tool rest);

- corner 62*62, 165 mm long (the tailstock will be made from it);

- a bolt with a length of 70 mm, useful for attaching the hand rest to the base;

- a piece of metal tube slightly larger than the diameter of the engine shaft;

- a bolt with a sharp tip (will be used as a rotating headstock assembly).

Don't forget to prepare the power supply wiring for the motor.

Tools and fasteners that will be needed during the work:

- drill;

- drills of various sizes;

- grinder and removable disks for it;

- nuts and bolts for fastening the main structural elements.

After all the tools and components necessary for the work have been prepared, you can begin the main work. Let's figure out how to assemble a homemade machine from an old washing machine motor.

How is it done?

If you decide to make a lathe yourself, you will have to be patient and have some free time. The assembly process will not be fast. First of all, it is necessary to prepare the foundation for the installation of all components of the structure. So, the algorithm of actions will be as follows.

- Clean the countertop.

- Attach the electric motor from the washing machine to the prepared base; for this you can use corners of suitable sizes.

- Assemble a tool rest from metal corners and square pipes.

- Using a drill and a drill bit of a suitable size, drill a hole in the tabletop to attach the tool rest, and secure the part with a bolt.

- Assemble the frame using a 62-mm angle iron and a sharp-tipped bolt.

- Fasten the tool rest and the tailstock together.

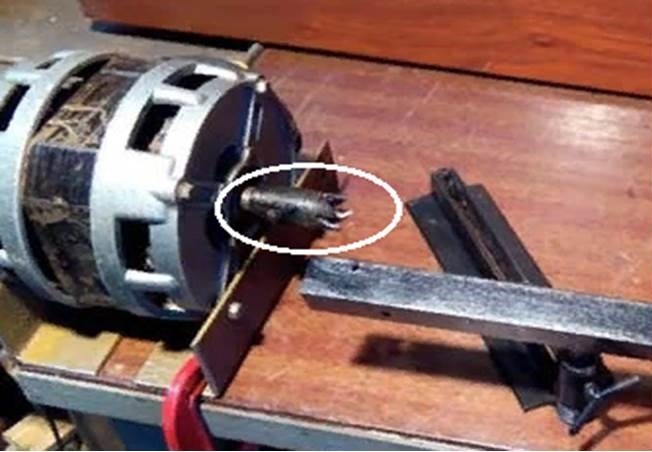

- Make an attachment for the electric motor shaft; it can be made from a piece of water pipe. The teeth of the nozzle are cut with a grinder.

- Weld the nozzle to the motor shaft.

- Connect the power supply to the motor.

By completing the following algorithm of actions, you will build a small wood lathe, which can be useful on the farm. The piece of wood to be processed is placed on the sharp tip of the engine shaft and the rotating tailstock assembly. Having started the device, you can begin turning work.

Areas of application of the machine

What is the scope of application of such an unusual homemade product? A small lathe for a home workshop, assembled with your own hands from an electric motor of a washing machine, can be used to make practically useful or decorative things from wood. Using a homemade device you can do:

- elements of interior or exterior decoration of the house;

- furniture parts;

- carved railings for stairs;

- tool handles;

- stools and much more.

In addition, a mini wood lathe can be used:

- for grinding the surface being processed;

- when applying threads with a certain pitch to the working surface;

- for drilling connectors in parts;

- for turning wooden elements.

As you can see, the scope of application of the machine is quite wide. Therefore, if the engine of an unnecessary washing machine is in working condition, you can give it a second life and use it to make a useful device for the household.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment