The washing machine tank is leaking

A tank leak is one of the most dangerous breakdowns for an automatic machine. In some cases, such a problem can be fatal. It is not difficult to recognize a leak - water will constantly accumulate under the device. It is the search for the location of the “leak” that causes the greatest difficulty for users.

A tank leak is one of the most dangerous breakdowns for an automatic machine. In some cases, such a problem can be fatal. It is not difficult to recognize a leak - water will constantly accumulate under the device. It is the search for the location of the “leak” that causes the greatest difficulty for users.

The washing machine tank often leaks due to worn bearings or seals. In this case, solving the problem will be quite simple. If the problem is damage to the wall of the plastic container, then the repairs will be more serious. Let's look into the nuances.

Why does the tank start to leak?

Problems with the tanks of automatic washing machines are happening more and more often. If the rules for operating and transporting washing equipment are not followed, the likelihood of damage to the tank increases. Modern washing machines are equipped primarily with plastic containers, so you need to handle them especially carefully.

A leak in the tank can occur for various reasons. Let's look at the main ones.

- The plastic was damaged during transportation of the washing machine. This can happen if you transport the machine gun without transport bolts. The container will not be fixed, so it will hit other internal parts of the device.

- The bearings and seal are worn out. In this case, rusty smudges can be found on the back wall of the tank.

- The wall is damaged by a sharp, hard object caught in the area between the tank and the drum. For example, this happens when a bra wire ends up inside the machine. When the washing machine operates at high speeds, it will be quite capable of piercing the plastic tank.

- The weld seam between the halves of the SMA tank has become leaky.This option is possible if the washing machine has not been used for a long time (for example, it has been in a store warehouse for several years). Another reason is a manufacturing defect.

What to do if you discover a leak? First of all, it is necessary to identify the cause. If the washing machine tank is leaking due to broken bearings or an old seal, replacing components will help. When it comes to damaging the walls, you have to be smart.

A crack in a plastic tank can be sealed, this will help eliminate the leak.

Washing machine repair technicians have been “fixing” cracked plastic tubs for a long time. The defect is sealed and the machine stops leaking. However, no one gives a guarantee for such repairs, since the treated area may begin to leak water again.

The ideal solution to the problem is to replace the tank-drum assembly. However, spare parts are quite expensive, and not everyone can afford such a purchase. Therefore, the user must decide for himself whether to solder the crack or purchase new components.

First, remove the tank from the housing

To understand why the tank of an automatic machine is leaking, the container will have to be removed from the body and inspected. Before starting work, turn off the power to the washing machine and turn off the valve responsible for the water supply. Also prepare the tools that will be needed in the process: pliers, slotted and Phillips screwdrivers, a screwdriver, a set of socket heads. The further algorithm of actions will be as follows:

- drain the remaining water from the system by unscrewing the garbage filter (it is located in the lower front corner of the MCA);

- using a screwdriver, remove the bolts holding the top panel of the SMA housing;

- remove the “lid” by first moving it a little back and then pulling it up;

- unscrew all the bolts holding the back wall of the machine;

- remove the back panel;

- remove the drive belt from the pulley;

- inspect the back of the tank of the automatic machine;

Having discovered rusty stains on the back of the tank, extending from its center, it is possible to ascertain damage to the seal and wear of the bearings.

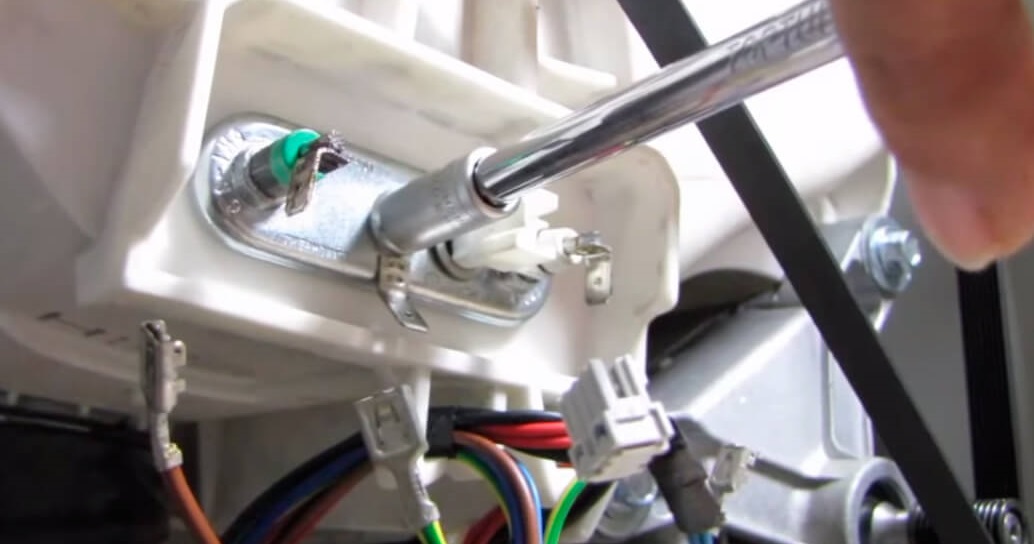

- unhook the heating element and temperature sensor wires from the SMA tank;

- Unscrew the bolts holding the washing machine motor;

- remove the heating element from the socket by loosening its nut;

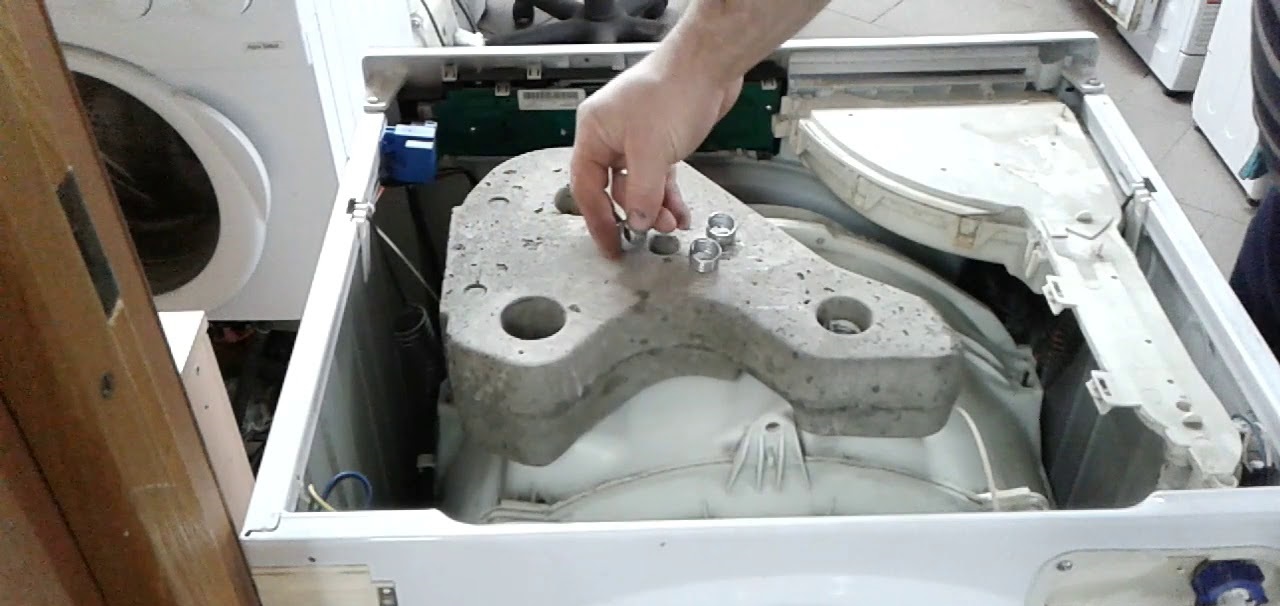

- remove the upper counterweights;

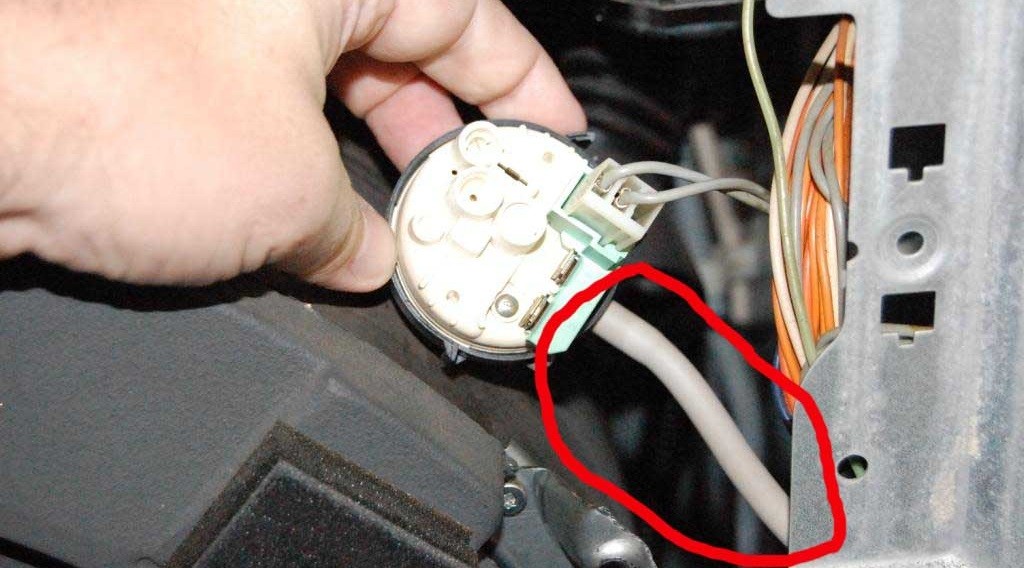

- disconnect the pipes and wires from the water level sensor, carefully remove the pressure switch from the machine;

- remove the detergent dispenser from the machine, then loosen the hose clamps leading to the powder receiver and remove the dispenser hopper;

- carefully place the washing machine on its right side, see if it has a bottom (if so, remove the tray by unscrewing the bolts holding it);

- remove the screws located on different sides of the drain filter;

- push the pump volute, where the debris filter is placed, inside the SMA housing;

- unhook the chip with wires from the drain pump, remove all the tubes from the pump;

- remove the pump from the SMA housing;

- unscrew the shock absorbers holding the tank from below;

- lift the washing machine (do this carefully, because the “tank-drum” assembly will be secured in the body with only two springs;

- Unscrew the bolts holding the SMA control panel, place the “tidy” on top without completely disconnecting it;

- open the drum door, loosen the clamp holding the cuff;

- pull the clamp out of the body, tuck the cuff inside the drum.

During the process, it is important to photograph the initial arrangement of the elements, as well as the diagrams for connecting the contacts to the parts - this will help you avoid mistakes during reassembly.

Now nothing will interfere with the removal of the tank.Remove the assembly from the shock absorbers and lift it out through the top of the housing. Next you will have to carefully inspect the tank.

How to solder a hole?

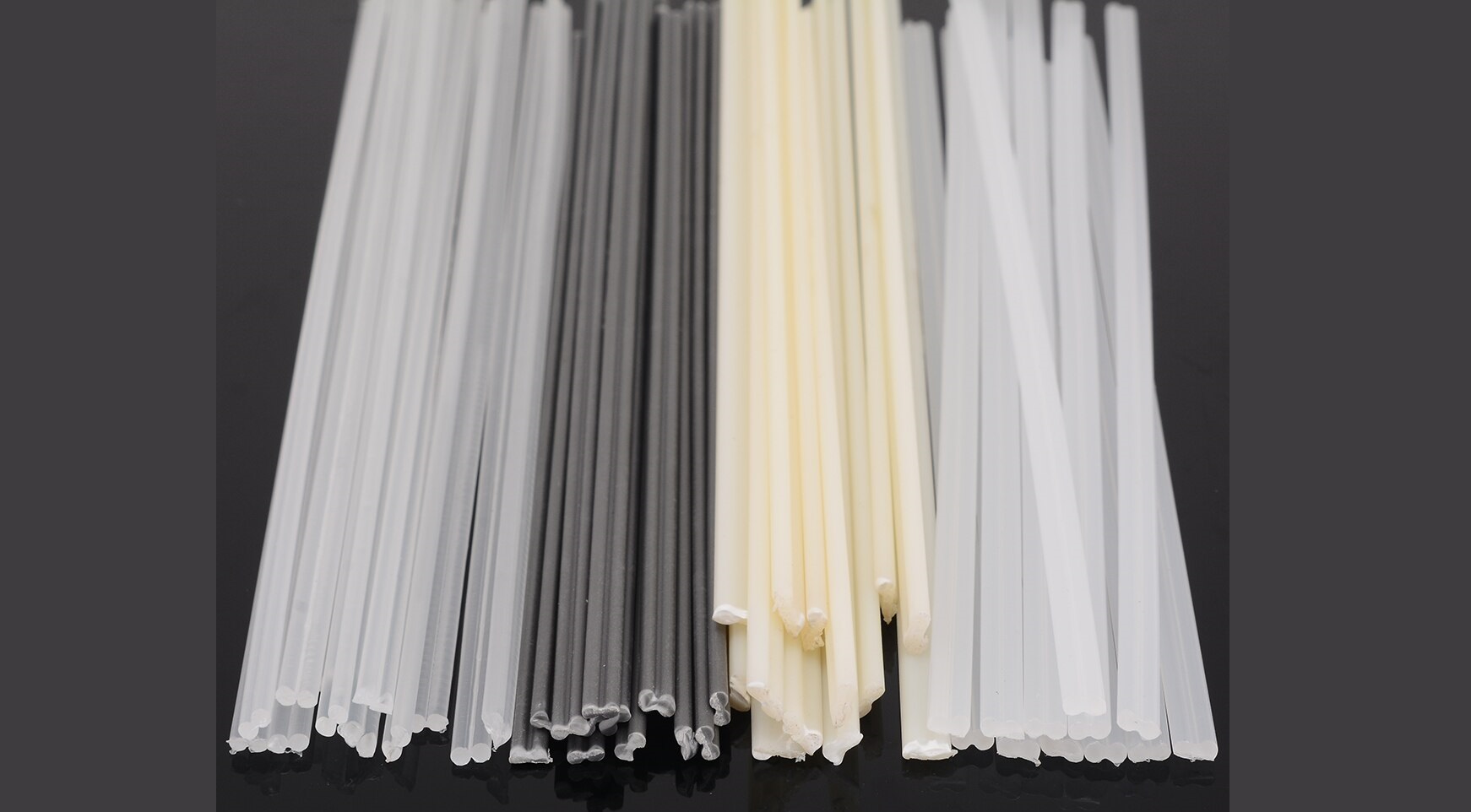

If the problem is not with the bearings, most likely the tank is leaking along the seam, or cracks have appeared on its walls. Holes in plastic can be sealed using a hair dryer and plastic solder. The cost of such repairs will be small; you can buy a pack of rods for $2-3. The amount of material that will have to be used depends on the size of the damage to the container.

In addition to the hair dryer itself, you will need:

- a nozzle that narrows the hole of the hair dryer (usually included in the kit);

- a welding nozzle that allows the introduction of filler material (rods);

- plastic solder in the form of rods.

Craftsmen who repair washing machines recommend purchasing HDPE plastic welding rods. They “grab” best with machine tanks, so they are suitable for local repairs of this kind.

The algorithm for sealing a tank crack will be as follows:

- Place the tank on a flat surface;

- put a narrowing nozzle on the hair dryer;

- take a welding nozzle and one rod;

- put a solder attachment on the hair dryer, turn on the tool, wait until the air becomes very hot;

- insert the rod into the nozzle and carefully “patch” the defect.

When the tank is leaking along the seam, process it in this way along the welding line. This may require about 10 rods. If you consider that there are 40 of them in a package, then you won’t have to buy an additional pack.

There is another way to repair a hole in a plastic tank - using a soldering iron. This method is suitable when the crack is small. In general terms, the algorithm of actions will be as follows:

- find a piece of plastic similar in quality to the material from which the tank is made (the craftsmen even saw off a small piece from the same SMA tank, in a place where its absence will not affect the operation of the device in any way);

- Place a piece of plastic over the crack and “melt” it with a soldering iron, so as to “patch” the defect.

After repairing the tank, you can put it back in place. Reassembling the washing machine is performed in the reverse order. During the process, it is recommended to check with previously taken photos to avoid mistakes when connecting wiring and pipes.

Once you're done with assembly, run a test wash. If the machine stops leaking, then the problem can be considered resolved. During further use, you need to monitor the condition of the “home assistant” and prevent foreign objects from getting into the washing machine drum.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment