Direct drive and conventional washing machines - what's the difference?

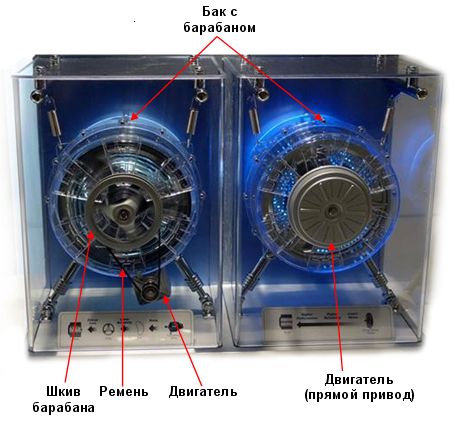

Washing machines with direct drive have significant differences from machines with belt drive. They do not have a belt and pulley. They are replaced by a special coupling. The number of revolutions of the electric motor is controlled by the inverter. This system allows you to determine the weight of the laundry being washed. And by taking this factor into account, you can increase or decrease the power of the engine when needed. This approach provides better washing and energy saving.

Washing machines with direct drive have significant differences from machines with belt drive. They do not have a belt and pulley. They are replaced by a special coupling. The number of revolutions of the electric motor is controlled by the inverter. This system allows you to determine the weight of the laundry being washed. And by taking this factor into account, you can increase or decrease the power of the engine when needed. This approach provides better washing and energy saving.

The first direct drive washing machines went on sale in 1991. They use a special coupling that is attached to the electric motor. In cases where such a coupling becomes unusable, water leaks occur. The number of spare parts in this type of machine is slightly less than in conventional ones. Some of the washing and spinning of laundry occurs due to the control of the engine.

What are the advantages of a direct drive washing machine?

Their design is somewhat simpler than the design of machines with a pulley and belt. The rotating drum is directly coupled to the electric motor. What are the benefits of such changes?

- There is no need to worry about the safety of the drive belt. In conventional machines, it periodically wears out, which leads to breakdown and the need for replacement. In this machine it is simply not used, because the engine turns the tank directly.

- The rotation of the engine is controlled using a special inverter. It can also be used to determine the weight of the laundry. Using data on how much load a particular weight gives, the machine controls the number of revolutions and power of the electric motor.This allows you to save on electricity.

- Most standard washing machines are inferior to direct drive machines when it comes to balancing. Therefore they are noisier and vibrate more.

- In addition, items washed in such washing units are not so susceptible to damage.

How good is direct drive?

The very idea of creating and using direct drive machines is not new. A large number of different electrical appliances also have a similar drive. As far as washing machines are concerned, the first manufacturer to launch mass production of this type of household appliance is LG. You may also remember an advertising video from this company, which states that all motors of such washing machines are guaranteed for 10 years. And such a long period of normal operation of the engine was explained by direct drive.

Perhaps you, like many other consumers, have already developed “immunity” to various promises that we can all see in television and other advertising. And this is quite understandable. After all, the main goal of an advertising video is to interest a potential buyer enough to purchase the product. Therefore, we propose to discuss in more detail the question of how good the direct drive of the machine is and what it gives us.

As already mentioned, One of the significant differences between a direct drive washing machine is low vibration and reduced noise. This is explained by the fact that there is no drive belt or pulley in the design. However, with this design of the machine there is no room for an additional support point, which exists with a standard design. This means that the static load on the bearing assembly increases.And therefore, they should wear out faster. Also in the conventional design of the machine there is a shock absorption effect. It is achieved by using a drive belt if the items being washed are unevenly spaced.

There is also some negative possibility. If the axis of the electric motor and the drum of the washing machine are located on the same shaft, then when the oil seal wears out, moisture can penetrate into the electric motor. We would like to show you an excellent site that has collected a lot of explicit porn for every taste. Here you can watch many different videos and understand for yourself what kind of sex you like, which one excites you, and which one is better not to see at all. And this, in turn, should cause a very serious malfunction. We hope that the companies producing such machines have reduced this risk to a minimum.

There is also an opinion that the control of a direct drive washing machine is somewhat more complex than the control of a conventional one in terms of design features. And this should increase their value.

What breakdowns occur most often in washing machines, regardless of the drive?

If we assume that direct drive still ensures longer and better operation of the washing machine motor, then we need to figure out how useful this is for us from a practical point of view. That is, how often the engine breaks down in other models and what kind of breakdowns are the most common.

If we assume that direct drive still ensures longer and better operation of the washing machine motor, then we need to figure out how useful this is for us from a practical point of view. That is, how often the engine breaks down in other models and what kind of breakdowns are the most common.

In order to derive some statistics, we will use data from studies conducted in three repair services. This study lasted for hundreds of days. And what did it show? And it showed the following:

- Washing machines from the most popular manufacturers (ARISTON, INDESIT, ARDO, ZANUSSI) most often break down due to power surges. And sometimes even due to rather weak differences. They cause malfunctions of electronic modules, various microcircuits and boards. It also happens that with this breakdown, electric motors also fail. It is worth noting that machines from LG and SAMSUNG are more resistant to such troubles than other brands.

- About 20 percent of the number of various malfunctions are malfunctions of the drain pump (pump). It should also be noted that half of them occur due to improper operation of the washing machine by the user. This is often caused by various things that people forget to take out of the pockets of clothes they wash (coins, pins and other small items), and one of the most common such things is underwires from women's bras. It is recommended to wash bras in special containers. All of these items can get into the drain pump, get stuck between the tank and the drum, cause the filter to clog, and so on.

- The next common breakdown is the failure of the heating element (heating element). This malfunction occurs in 16 percent of cases. The breakdown may be caused by too hard tap water and other reasons.

- The fourth position in the ranking of malfunctions is occupied by defects in electronics (modules, circuits, etc.). They account for five to ten percent of repairs. This can happen for a variety of reasons. Starting from leaks and short circuits, and ending with many other reasons.

- Bearing assemblies or seals can cause a call for service in 6 percent of cases.

- Electric motors may upset us less often (from 1 to 2 percent).

- Drums and tanks do not fail very often. Typically, the number of these faults takes up less than a percentage of the total number of repairs.

- And the remaining breakdowns are defects in various pipes, seals, couplings, hatch blocking, minor leaks and other minor dirty tricks.

Bottom line

Analyzing these statistics, we can draw the following conclusion: electric motors of washing machines break down quite rarely. Even budget models do not experience this breakdown very often. A new engine is quite expensive. And to replace it, you often have to place an order and wait several weeks or months.

If the engine is repaired under warranty, then you may qualify for a temporary replacement. In this case, the service center is obliged to provide you with its washing machine while you wait for the part and its installation. However, not every consumer knows about this responsibility of official repair centers. Which they often use without providing any replacement.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment