The water in the Zanussi washing machine does not heat up

When a Zanussi machine does not heat water, many users try to immediately replace the heating element. In most cases, this helps, but the malfunction can also be caused by other reasons. Let’s figure out which elements of the machine should be checked in order to solve the problem of washing in “icy” water.

When a Zanussi machine does not heat water, many users try to immediately replace the heating element. In most cases, this helps, but the malfunction can also be caused by other reasons. Let’s figure out which elements of the machine should be checked in order to solve the problem of washing in “icy” water.

Looking for a broken element

Noticing that there is no heating is very simple. Firstly, condensation accumulates on the hatch door of the machine - this is a clear sign that the glass is washed with cold water. Secondly, things wash worse - stains still remain on the fabric after the cycle.

Typically, the automatic machine continues to operate normally, despite the impossibility of heating. Sometimes the washing machine freezes at the beginning of the cycle and displays an error code E61 or E62. It is better to solve the problem as soon as possible.

The easiest option is to transfer the machine to a service center for diagnostics and repair. But this method entails additional costs. You can try to deal with the breakdown yourself; to do this, you need to identify the range of possible faults.

The reason that the water does not heat up during washing may be:

- broken heating element;

- break in the heating element circuit;

- damage to the thermostat circuit or breakdown of the temperature sensor itself;

- clogging or malfunction of the pressure switch;

- problem with the main electronic module;

- crashed firmware.

It is very difficult to understand what exactly happened to the machine just by “symptoms”. Therefore, you will have to carry out a classic diagnosis of the machine. Let's figure out how to perform the check correctly.

Checking the heating element

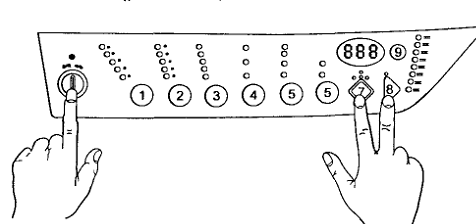

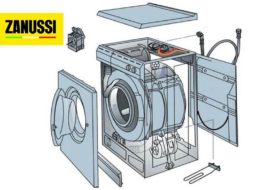

Of course, first of all you need to inspect the heating element.The element is located on the back of the machine, directly under the tank. The tube heater is easy to access. It is necessary to “halve” the body. For this:

- Find the bolt below, on the right wall - it is “hidden” behind a special plug. Unscrew the screw. Repeat the manipulation with the left panel of the case;

- Unscrew a couple of screws securing the “top” of the machine. Remove the cover and set it aside;

- unhook the drain hose. It is attached to the rear panel;

- disconnect the housing element from the back wall (it is made in the shape of a semicircle, the power cord is inserted through the hole in it). To do this, you need to bend the special tab;

- Unscrew two bolts located on top of the right and left panels;

- move the back of the case away from the front.

This is how the case is disassembled. In general, you only have to unscrew 8 bolts.

To diagnose the heating element, you will need a special device - a multimeter.

After disconnecting the back part, you can see the “insides” of the machine. The tank will immediately catch your eye - the heating element is located under it. Take a photograph of the wiring diagram for the heating element and temperature sensor to avoid mistakes when subsequently restoring the circuit.

The further algorithm of actions is as follows:

- disconnect the wiring from the heating element and thermostat;

- start the multimeter, switch it to resistance measurement mode;

- attach the tester probes to the contacts of the tubular heater;

- evaluate the values on the device display.

If the multimeter screen displays a number from 26 to 28 Ohms, then the heating element is working. A one on the display will indicate an internal break, and a zero will indicate a short circuit of the element. If you see “1” or “0” on the display, you will have to change the tubular heater.

If the multimeter shows normal values, you should check the heating element for breakdown. You need to switch the tester to buzzer mode and place the probe against the element terminal. If the device beeps, then you cannot do without replacing the heater.

If it turns out that the reason for the lack of heating is a failed heating element, you will have to replace it. To remove the tubular heater from the “socket”, you must:

If it turns out that the reason for the lack of heating is a failed heating element, you will have to replace it. To remove the tubular heater from the “socket”, you must:

- treat the rubber seal with WD-40 spray;

- wait 15-20 minutes;

- remove the temperature sensor;

- loosen the central nut, remove the fixing bolt;

- lightly rock the element and remove it from the housing.

The replacement heating element is selected strictly according to the serial number stamped on the part body.

It is best to dismantle the heater and go straight to the store with it. The specialist will select a similar heating element suitable for a specific Zanussi model.

Before installing a new part, it is important to clean the seat from accumulated dirt and limescale. It is also better to stick your hand into the “socket” and check if a foreign object is lost between the tank and the drum. Then you can install the heating element and connect the wiring, focusing on the photos taken earlier.

Sensor that monitors the amount of water

Oddly enough, sometimes the water does not heat up when washing precisely because of the pressure switch. You can find the part under the top cover of the machine, on the right. The water level sensor resembles a washer; a long hose extends from it into the tank.

To check the pressure switch, you must:

- prepare a tube whose diameter will correspond to the size of the sensor fitting;

- disconnect the long hose by removing the clamp;

- insert the tube into this hose and blow into it;

- listen. If 2-3 clicks are heard, it means that the pressure switch contacts are triggered.

This is only the first stage of diagnosis.Next, you need to inspect the level sensor, make sure that there are no cracks, signs of burning or other damage on the “washer” and the pipe. Afterwards, be sure to check whether the hose is clogged.

Then, the most important thing is to check the pressure switch with a multimeter. The algorithm will be like this:

- study the sensor wiring diagram. A description of the contacts is presented in the instructions;

- switch the tester to resistance determination mode;

- attach the multimeter probes to the contacts of the level sensor;

- evaluate the numbers on the device display. If the initial value changes, then everything is in order with the pressure switch.

Having identified a malfunction, do not try to repair the pressure switch; it is easier to buy a new element. To remove a non-working level sensor, you need to loosen the clamps, remove the wiring chip and remove the “washer”. The working part is installed in the reverse order.

If the heating element, thermistor and pressure switch “passed” the test, it is likely that the cause of the machine malfunction lies in a damaged control board. It’s not worth getting into the “brain” of a machine gun without the necessary knowledge and experience. It is better to entrust such repairs to a specialist.

Interesting:

1 reader comment

Cool, everything is accessible, clear