Weissgauff washing machine does not spin

If at the end of the cycle there is water left in the drum and the laundry is completely wet, there is only one conclusion - the Weissgauff washing machine does not spin. Why could this happen? It's not always a malfunction; sometimes it's simply user inattention.

If at the end of the cycle there is water left in the drum and the laundry is completely wet, there is only one conclusion - the Weissgauff washing machine does not spin. Why could this happen? It's not always a malfunction; sometimes it's simply user inattention.

Let's figure out why the washing machine may refuse to spin things. We'll tell you where to start diagnosing. We will explain in what cases you can repair the machine yourself, and when it is better to call a specialist.

What problem caused the problem?

Having noticed that the machine has stopped spinning things, it is better to immediately find out the reason why this is happening. If the problem is a breakdown, then over time the situation will become even more dire. Therefore, there is no need to put off diagnosing SMA for a long time.

So, the reasons why the Weissgauff washing machine may not spin are the following:

- the user has selected a program without spin;

- the system has detected an imbalance of the drum;

- the drain does not work;

- the operation of the electric motor is disrupted;

- the tachometer has failed;

- the bearing assembly is severely damaged;

- the control module fails;

- a foreign object is stuck between the tank and the CMA drum, blocking the rotation of the container.

Modern SMAs display an error code corresponding to the malfunction.

Therefore, if the lack of spin is accompanied by an error on the display, decipher it. A description of each fault code is in the equipment instructions. Some combinations indicate problems with the drain, others with the motor, etc.

You can deal with most problems yourself. Help from a service center specialist will be required if the problem is in the electronic control module.Diagnostics are performed sequentially. We'll tell you where to start checking.

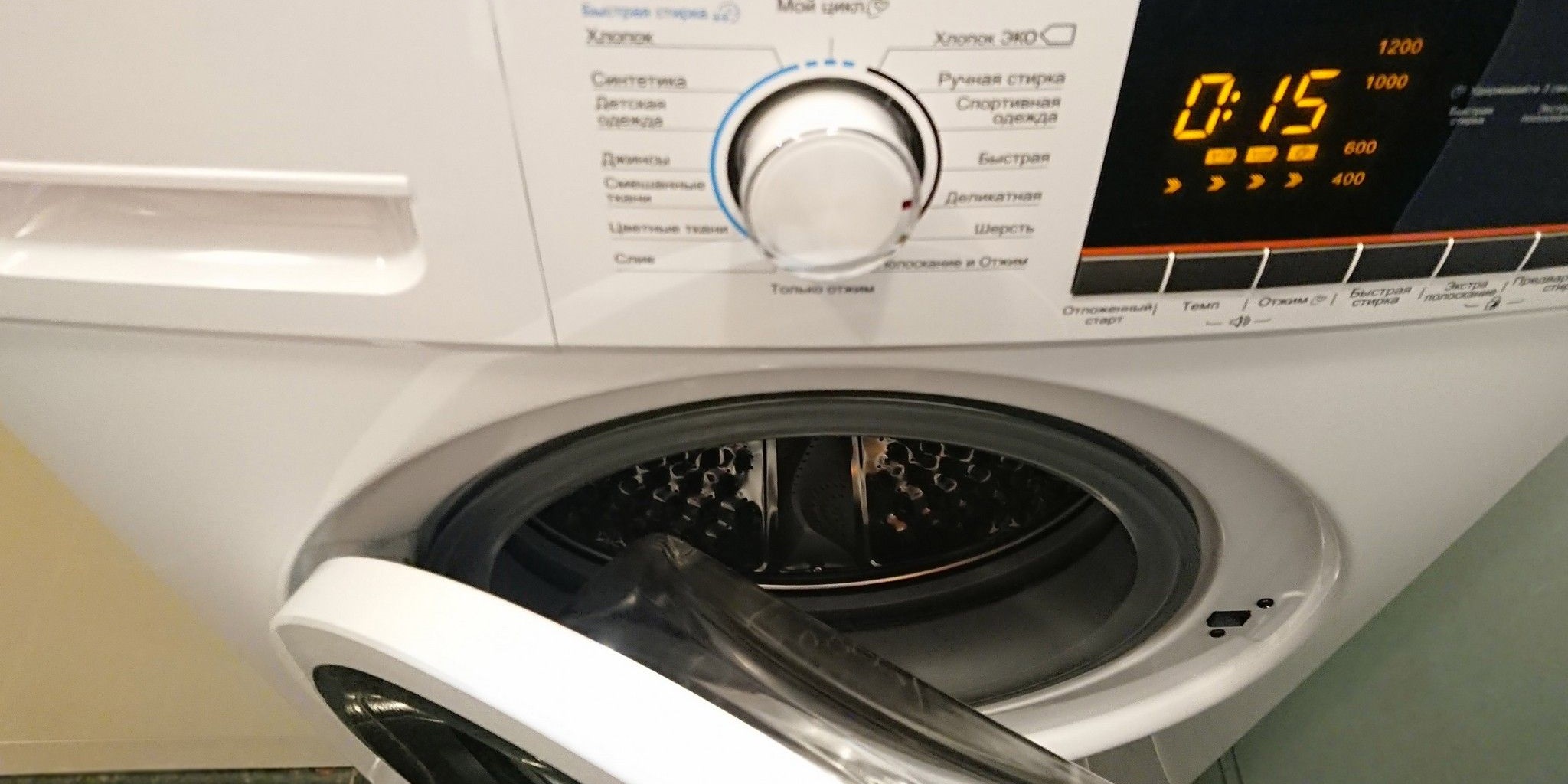

Does spin not work on all programs?

First you need to understand that this is not a matter of simple user inattention. Perhaps the machine was given a command to perform a delicate program in which spinning is not possible. Or the housewife accidentally touched the touch button that activates the “No spin” option.

Remember which mode was launched last. Read its description in the machine manual. Perhaps the program settings really do not provide for spinning, or it is performed at minimum speed, so the laundry seems too wet.

You should also check whether the spin cycle was accidentally canceled during the normal program. To do this, you need to activate the test cycle. Select any short standard mode on the machine, make sure that the spin speed is set (at least 800 rpm), and start the wash.

The machine will probably wring out the items calmly and complete the cycle. So it really was a matter of simple inattention. To prevent a similar situation in the future, it is better to block the SMA control panel. Then you simply won’t be able to press a button by accident.

Linen bunched up

Sometimes the washing machine does not start spinning due to an imbalance. The system records the unlocking and stops the cycle. Then the things inside the machine remain wet.

What causes imbalance:

- overloading the machine with laundry;

- insufficient loading (if there are few things in the drum, this is just as harmful as when there are a lot of them);

- uneven distribution of laundry inside the drum (in this case, things clump together and put increased pressure on one side).

An imbalance is possible with old-style Weissgauff models - modern washing machines can prevent drum imbalance.

It is very easy to suspect an imbalance. In this case, the machine will unsuccessfully try to spin the spin drum several times. As a result, the washing program will end 10-15 minutes earlier, and the clothes will remain wet. Machines with a display will display the corresponding error code on the screen.

What to do in such a situation? Enough:

- wait until the washer hatch unlocks;

- open the door;

- if it is overloaded, remove some of the laundry from the machine; if it is underweight, add a few items to the drum; if it is bunched up, evenly distribute the clothes inside the washing machine;

- close the hatch door;

- run the “Drain+Spin” option.

It is better not to allow the drum to become unbalanced. An imbalance has a detrimental effect on the shock-absorbing elements, bearings, spider and shaft. It is important to control the weight of laundry loaded into the washing machine, taking into account both the upper and lower permissible limits. For example, in a 7 kg Weissgauff machine you can wash at least 2 kg of clothes, and in a 5 kg machine you can wash at least 1 kg of clothes.

Sewage does not leave the tank of the machine

If the washer stops with a full tank of water, there are problems with drainage. You will have to check whether there is a blockage in the system, how the pump functions, and whether the pump impeller is blocked. Diagnosis of SMA elements is performed in a certain order.

To begin with, the drain hose is disconnected from the siphon or sewer pipe. It is necessary to feel the corrugation along its entire length for blockages. If a seal is found, unhook the sleeve from the SMA body and rinse under a strong stream of water.

The issue may be a clog in the sewer pipe or siphon itself. In this case, you need to lower the end of the CMA drain hose into the sink or bathtub.Next, the “Drain + Spin” option is launched. If the machine calmly finishes its work and spins out the laundry, then the problem is truly external and has nothing to do with the washing machine.

Next in line for inspection is the garbage filter. It is located in the lower right corner of the Weissgauff machine. Open the hatch with a screwdriver, place a container under the washing machine to collect water and unscrew the filter element. Clean the part and the seat itself.

To check the pump, you need to look under the washer. He is also inspected for blockages. Often the problem is in the impeller, the rotation of which is blocked by debris. Clean the part, and if this does not help, test the pump with a multimeter.

The tachometer is "jamming"

The washing machine will not be able to wring out things if the tachogenerator is broken. The Hall sensor monitors the number of revolutions made by the electric motor and transmits this information to the control module. If it malfunctions, the operation of the automatic machine is disrupted.

If the tachogenerator breaks down, the “brain” of the SMA does not receive information about the operation of the engine, and for safety reasons, reduces the power of the electric motor.

Such a breakdown can be caused by:

- the user regularly exceeds the maximum loading weight of the AGR;

- prolonged use of the Weissgauff washing machine without stopping;

- loose element fastenings;

- damaged wiring or oxidized contacts;

- short circuit;

- power surge.

To begin with, the wires connected to the tachogenerator are inspected for defects. Check if the contacts have come loose. When they are oxidized, cleaning is performed. Then the Hall sensor itself is checked with a multimeter. If the measurement results do not meet the standard, the part will have to be replaced; the tachometer cannot be repaired.

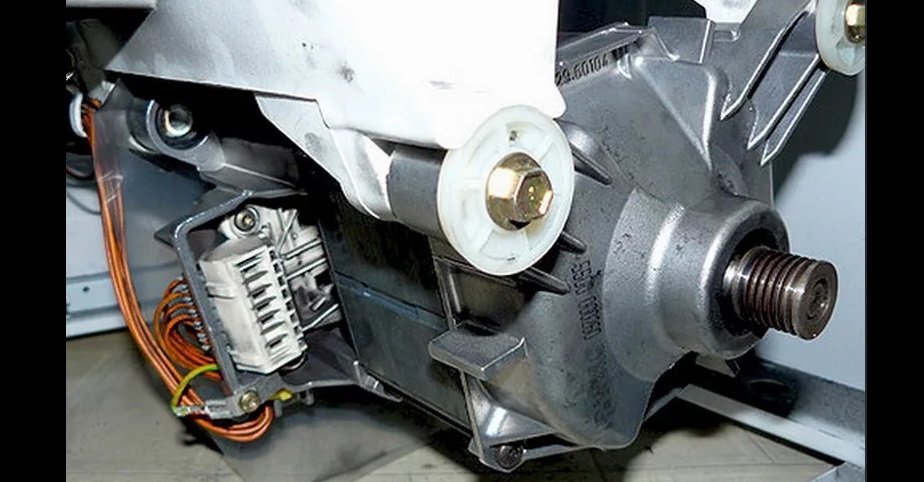

The engine doesn't have enough power

In some cases, the engine power is not enough to spin the drum to the required speed. In commutator motors, braking occurs when the brushes are worn out - the “fuse” is enough for washing and rinsing, but not for spinning. If all stages of the cycle occur with difficulty, the motor winding may break.

To check the electric motor, you will have to remove it from the machine. For this:

- de-energize the SMA, disconnect it from the water supply and sewerage;

- remove the back panel of the Weissgauff case;

- remove the drive belt from the pulley;

- loosen the engine clamps;

- swing the motor and pull it out of the grooves.

Afterwards, the engine body is wiped with a napkin and inspected for defects. Check if the electric brushes are worn out; if there is severe wear, replace the graphite rods. Test the coils with a multimeter. A burnt-out motor emits an unpleasant odor, and there will also be dark spots on its surface. In this case, the element will need to be replaced.

Electronics are to blame for the problem

The most unpleasant thing is when the problem is in electronics. In this case, the semiconductor responsible for spinning burns out on the board. Because of this, the engine does not receive commands to accelerate and cannot spin the drum to the required speed.

It is better to entrust diagnostics and repair of the electronic control unit to specialists.

It is not recommended to repair the control module yourself. Lack of knowledge and experience can only make the situation worse. A new unit is expensive; it will be cheaper to pay for the services of service center specialists.

Bearing unit

Over time, Weissgauff washing machines may have bearings that break. There are several signs of this breakdown. If the bearing assembly is damaged, there is a strong rumble and knocking during the cycle, rusty smudges on the tank at the location of the shaft, as well as problems with spinning.

Repair of the washing machine will consist of: replacing bearings and seals. You will have to almost completely disassemble the automatic machine and remove the tank from it. Next, the plastic container will be halved - the metal rings are “hidden” inside.

To remove broken bearings you will need a puller. It's also a good idea to have WD-40 on hand. New components are selected for a specific Weissgauff model, according to the CMA serial number.

Before undertaking such repairs, you should really evaluate your strengths. The work ahead is quite complex and time-consuming. There is a high probability of breaking a wire during disassembly, damaging the pipes, or carelessly removing a part. But the services of a specialist will not be cheap - usually the fee for such a procedure is a third of the price of a new SMA.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment