Why does my LG washing machine take a long time to spin?

If an LG washing machine spins for a long time, it is immediately noticeable. After rinsing, the machine does not accelerate to the set speed, “freezes” and slowly rotates the drum. As a result, the equipment erases endlessly instead of the allotted 3-5 minutes or freezes completely. It is useless to wait for the end of a prolonged spin cycle - the washing machine will no longer be able to complete the program. It is necessary to forcefully stop the cycle, and then look for and eliminate the cause of the braking.

If an LG washing machine spins for a long time, it is immediately noticeable. After rinsing, the machine does not accelerate to the set speed, “freezes” and slowly rotates the drum. As a result, the equipment erases endlessly instead of the allotted 3-5 minutes or freezes completely. It is useless to wait for the end of a prolonged spin cycle - the washing machine will no longer be able to complete the program. It is necessary to forcefully stop the cycle, and then look for and eliminate the cause of the braking.

Drum overload, imbalance or dampers

The washing machine cannot spin normally in two situations: if it is unbalanced or if there are problems with the motor. The first option is more common and can be resolved faster - it is enough to eliminate the cause of the drum imbalance. As a rule, there are three of them:

- exceeding the maximum drum load;

- insufficient amount of things in the tank;

- "clumping" of laundry.

Normally, the LG washing machine spins in 3-6 minutes!

As a rule, the problem lies in non-compliance with loading standards. If you put too much laundry in the drum, the weight will increase when wet, and a special sensor will detect the overload. For protection purposes, the system will not allow the engine to accelerate to spin, so as not to damage the crosspiece, shaft and other elements of the washing machine. The solution is simple: open the hatch, lay out some of the things and start the machine again.

A similar situation will arise with underload. A drum that is too light during the spin cycle will go astray and lead to imbalance. Therefore, each LG has two parameters: both maximum and minimum loading weight.

The washing machine spins endlessly even if the laundry folded in the drum is bunched up.Due to the uneven distribution of the fabric, an imbalance occurs - one side outweighs, and the cylinder plays. To correct the situation, you need to stop the wash, separate the items and restart.

LG washing machine spins for a long time due to problems with drum balancing!

Another reason is problems with depreciation. When one of the dampers loses the necessary elasticity, the vibration emanating from the rotating drum is not properly damped. The washing machine begins to jump, play in the tank appears, and the automatic imbalance control “sounds the alarm.” The board reads the signal and, for safety reasons, does not allow the engine to accelerate, slowing down the spin cycle.

Pay attention to the Hall sensor or motor

If there are no hints of imbalance or problematic damping, then there is another option left - the engine. More often, the problem is a faulty tachogenerator - a Hall sensor that controls the speed gained. Without such control, the engine begins to spin chaotically: suddenly change speed, slow down or freeze. To make a diagnosis, the “counter” needs to be checked.

To check, the Hall sensor must be removed. We proceed according to the following instructions:

- disconnect the machine from the power supply and water supply;

- disconnect the back wall from the body;

- tighten the drive belt;

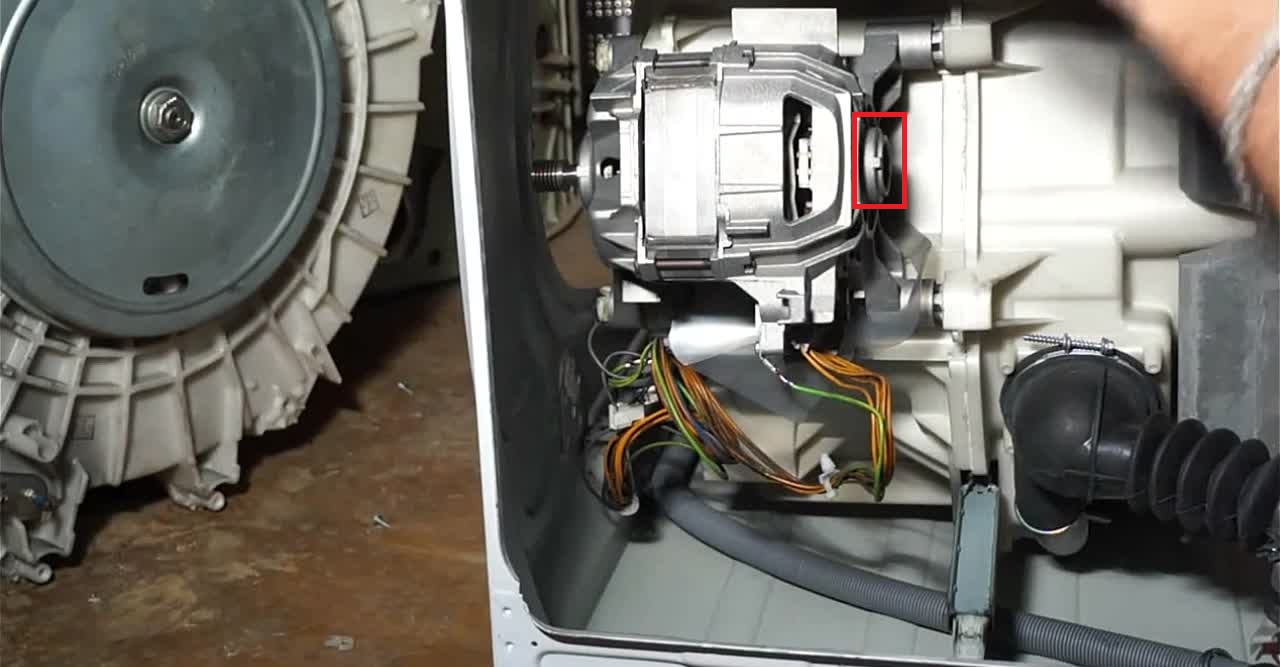

- find the electric motor under the washing tub;

- photograph the location of the contacts;

- release the “chip” from the wires;

- Unscrew the bolts securing the engine;

- “drown” the motor into the “socket” (it is permissible to gently tap the element with a mallet);

- pull out the engine;

- unhook the Hall sensor.

The next step is to check the sensor. The multimeter probes cling to the contacts, and the value displayed on the display is compared with the norm. If “0” or “1” appears, it means the tachogenerator is faulty. A broken device must be replaced, for which you must purchase one that matches the model. LG analog.

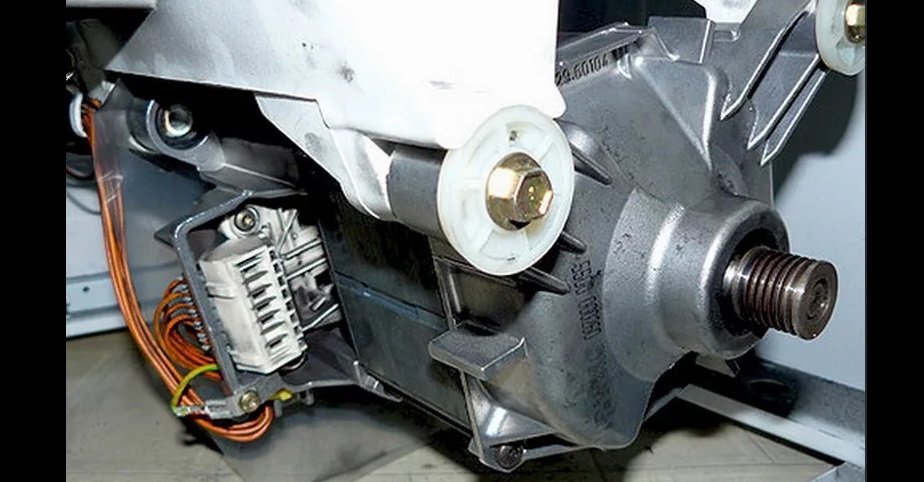

If there are no problems with the sensor, then you should inspect the motor itself (not suitable for machines with an inverter motor). The commutator has a weak side - electric brushes, which, when the motor is running, rub against its body and eventually need to be replaced. To check the condition of the graphite rods, you will have to:

- unhook two “cases” from the body (on both sides of the engine);

- unclick each brush;

- compress the spring mechanism and remove the graphite rod;

- measure the length of the “coals”;

- remove the old rods if at least one of the brushes is not long enough (an important nuance - brushes are always replaced in pairs);

- fix the new brushes on the motor.

The motor is faulty and has a damaged stator winding. In this case, the electric motor loses power and does not gain the proper speed, although outwardly it seems operational. It is difficult to visually determine the problem; it is better to use a multimeter and test the wiring for a breakdown. It is important to examine each turn, since leakage can be local.

Problems with the engine are indicated by a burning smell, sparking and melted insulation on the contacts.

A broken winding cannot be repaired. The engine will have to be replaced completely. When purchasing a new motor, you need to rely on the serial number of your LG washing machine. In order not to make a mistake in selecting an analogue, you should bring an old device to the store and ask a consultant to find an analogue.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment