Indesit washing machine does not switch to spin mode

If the Indesit washing machine does not switch to spin mode, then you should not put up with the situation and wring out the laundry with your hands. An unspun drum is the first warning of a breakdown, and leaving the problem without diagnosis and repair can aggravate the situation until the entire machine fails. It is better not to hesitate and immediately begin troubleshooting the problem. How to act and in what direction?

If the Indesit washing machine does not switch to spin mode, then you should not put up with the situation and wring out the laundry with your hands. An unspun drum is the first warning of a breakdown, and leaving the problem without diagnosis and repair can aggravate the situation until the entire machine fails. It is better not to hesitate and immediately begin troubleshooting the problem. How to act and in what direction?

Main symptoms of a malfunction

First you need to catch the alarming symptoms. The machine does not always just slow down in the middle of the cycle; sometimes it signals a breakdown with a problematic drain or an uncharacteristic hum. As a rule, you should be wary if:

- the running program has ended, but the water remains in the drum;

- items taken out are completely wet;

- water draining is very noisy or slow;

- the machine spins every once in a while or does not always respond to the set mode;

- the unit hums, as if spinning, but the drum stands still.

If at least one “symptom” is noticed, then you should be wary and find out the reason for the non-working spin cycle. Possible problems include both minor and quickly fixable breakdowns and large-scale malfunctions requiring the replacement of expensive parts. What can happen?

- Exceeding the maximum load or underweight. When too much or too little laundry is loaded into the machine, the system automatically cancels the spin cycle for safety reasons. Otherwise, imbalance and internal mechanical damage to parts will occur.

- Loose drive belt. The drum will not spin if the drive belt is stretched, has fallen off, or is slipping on the pulley.

- Failure of the control board or its semistors.If the triac responsible for transmitting information from the engine has burned out, then the system is not able to control the situation and control the machine. An error is displayed and the electronics are automatically turned off for safety reasons.

- Motor malfunction. It is logical that an engine not running at full power will not be able to accelerate the drum to the required speed. The cause of braking will be burnt wires, worn brushes, internal problems of the engine or a breakdown of the Hall sensor.

Knowing the signs and possible causes of missing spin, it is easier to determine the nature and extent of the problem. In any case, you need to act and not let things take their course. What you need to do first and how to repair the machine, we will tell you further.

Initial actions

A non-rotating drum does not always indicate serious internal problems with the washing machine. Often the matter is simple inattention, so it is recommended not to rush to disassemble the case. It's better to check.

First of all, check if the no-spin mode is turned on.

- Is the no-spin mode enabled? Often, users accidentally reduce the speed to a minimum or select the “Delicate” or “Hand Wash” non-spin program.

- Has there been a technical failure? It is rare, but it happens that the washing machine does not spin due to a short-term system failure. It is enough to turn off the machine, wait 10-20 minutes and start the cycle again.

Another possible option is to overload the drum. It is prohibited to exceed the maximum permissible weight of the laundry, because this risks imbalance, increased vibrations and mechanical damage. The situation is similar with a half-empty tank - the system will not risk the machine and start the cycle.

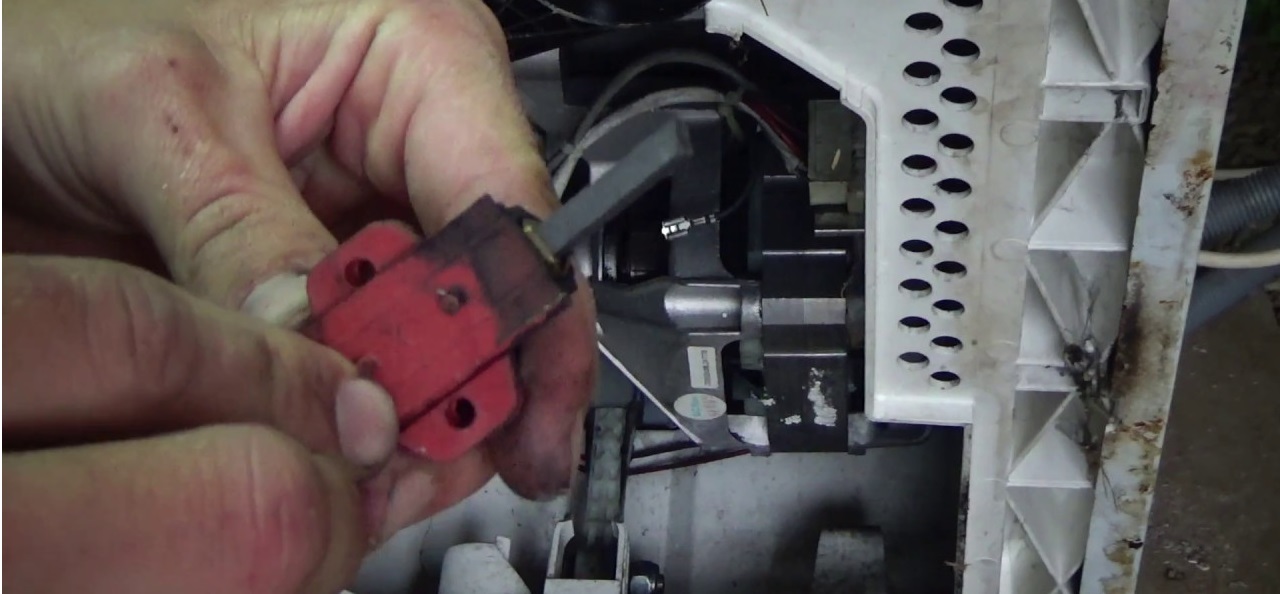

Let's check the electric brushes

Worn brushes often lead to problematic push-ups. As a rule, in this case the machine does not make a suspicious hum, but simply does not spin the drum to the required speed. Let's check the guess like this:

- disconnect the machine from communications and provide free access to the rear wall;

- remove the back panel by unscrewing the bolts around the perimeter;

- by rotating the pulley, remove the drive belt;

- Unscrew the bolts holding the motor;

- photograph the location of the wiring connected to the engine;

- loosen the connected wiring;

- swing the engine and remove it from its seat;

- We snap off the brushes and look at the condition of the carbon tips.

If one of the graphite tips is severely worn out, they need to be replaced. It is important that brushes are replaced only in pairs, despite the condition of the second copy. Replacement parts are purchased from the store strictly according to the old model, and installed according to the already discussed scheme in the reverse order.

Problems with the control module

Possible breakdowns include a faulty control board. Probably, the triac responsible for the motor has burned out or the “track” soldered to it has worn out. In any case, you need to remove the module and carefully inspect it.

- Disconnect the machine from electricity.

- Remove the top cover.

- Remove the dispenser tray by pulling it towards you.

- Unscrew the bolts holding the dashboard.

- Unlock the plastic latches and remove the panel.

- We release the connected wiring.

- We remove the module by releasing another pair of latches.

More often than not, one glance at the board is enough to notice traces of burning, dark spots or loose contact. If a visual inspection does not help, it is better not to experiment and contact a service center.

Prevention of breakdowns

It is better not to look for reasons, but to prevent them. Moreover, the basic rules for using the machine are simple and elementary. So, all you need is:

- install the machine according to the instructions;

- carefully check the pockets of items loaded into the drum;

- sort things and use protective bags;

- connect a voltage stabilizer to the network;

- control the tank loading level;

- Clean and ventilate the machine regularly.

By noticing problems with the spin cycle in time, you can significantly save your time and money. You just need to not hope for chance, do diagnostics and remember about prevention.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment