Bosch washing machine knocks out the machine

It’s unpleasant when the washing machine breaks down: the cycle is interrupted, the laundry remains dirty, and at the same time the lights in the whole house go out. Sometimes the electricity in the apartment does not suffer, but large household appliances, such as a washing machine, are not plugged into the outlet. In any case, it is dangerous to leave the incident unattended - it is necessary to check the electronics as soon as possible.

It’s unpleasant when the washing machine breaks down: the cycle is interrupted, the laundry remains dirty, and at the same time the lights in the whole house go out. Sometimes the electricity in the apartment does not suffer, but large household appliances, such as a washing machine, are not plugged into the outlet. In any case, it is dangerous to leave the incident unattended - it is necessary to check the electronics as soon as possible.

Before you arm yourself with screwdrivers and a multimeter, you should figure out why the washer knocks out plugs. We offer an analysis of typical causes with step-by-step instructions for eliminating them.

Why did the problem occur?

If the Bosch machine suddenly turns off, and along with it other rooms are de-energized, then going to the electrical panel, turning on the toggle switch and continuing to wash is strongly not recommended. Even a single operation of the machine indicates an overload in the electrical network and requires comprehensive diagnostics. A careless attitude to the problem with a temporary “solution” is fraught with aggravation of the situation - with the next overvoltage, a short circuit will occur, followed by a fire.

You can’t hesitate - it’s better to take care of the safety of residents and property, find the reason for the knocked-out traffic jams yourself, or contact professional electricians. The task is made easier by the fact that a limited range of faults can lead to such a reaction in the electrical network. So, the RCD on the machine is triggered in the following cases:

- an inappropriate RCD or circuit breaker is included in the circuit;

- the wiring is outdated;

- the load on the network has increased, and the wiring can no longer cope;

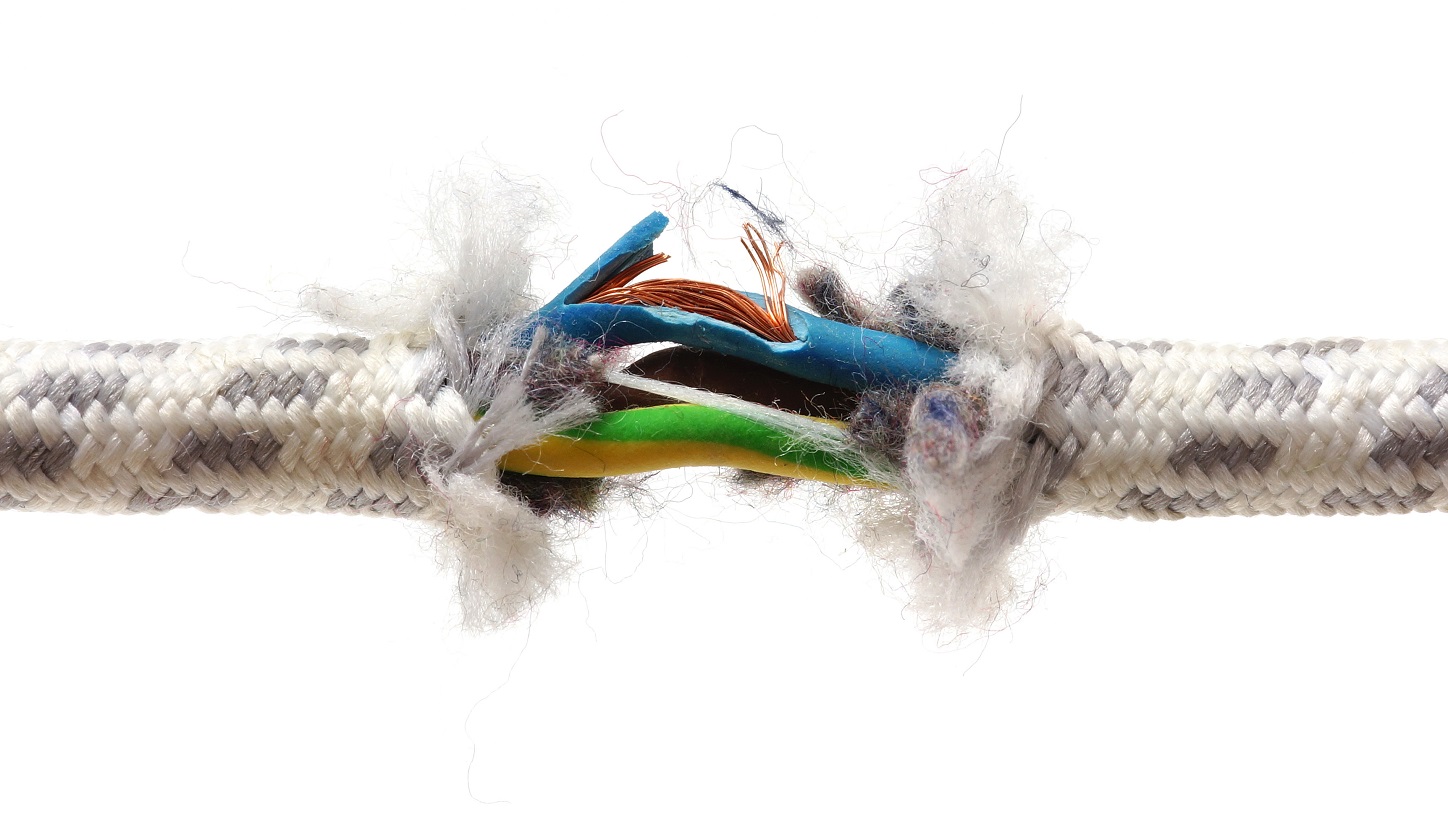

- The power cord of the washing machine is shorted;

- the socket allocated for the washing machine is broken;

- the buttons on the dashboard of the Bosch washing machine are closed (usually the “Start” key);

- the network filter is faulty;

- the control board has failed;

- the terminals inside the washing machine are burnt out or the wiring is damaged;

- The heating element or electric motor has broken down.

To check the electrical network, you will need a multimeter, an indicator, slotted and Phillips screwdriver.

To determine what exactly causes the plugs to be knocked out, it is necessary to sequentially check each “sore spot”. First, the most frequent and easy-to-fix faults are assessed, and then labor-intensive and large-scale breakdowns. In any case, only experienced and familiar with electrical technicians can begin diagnostics and repairs. If you have doubts about your abilities, it is better to turn to professionals.

Let's check the electrical network

When turned on and running, the machine puts a significant load on the electrical network. Manufacturers of household appliances, including Bosch, warn about the “electrical gravity” of washing machines and prescribe certain requirements for its operation. Among them, there is the need to allocate a separate branch for SMA, protected by RCDs and automatic devices. The type of wires is also recommended: VVG cable with a cross-section of 3x2.5. It doesn’t matter what washing model you buy, compact, full-size, equipped with a dryer or not.

In reality, users do not follow safety precautions. More often, the washing machine is connected to a common outlet with other household appliances, through an extension cord or “tee”. All this leads to overheating and damage to the wires, after which the socket melts, the RCD is triggered and the light turns off. It’s easy to suspect something is wrong: the insulation on the conductors is dark, the plastic is melted, and you can hear a burning smell.

You can avoid network congestion and subsequent problems if:

- allocate a separate branch for the washing machine;

- evaluate the quality of the installed wiring;

- insert a moisture-resistant socket (has a special lid);

- include an RCD in the circuit.

It is strongly not recommended to connect the washing machine to the network through an extension cord or adapter - it is dangerous!

If there are no visible signs of overheating and damage to the wires and socket, then you need to check the power cord from the inside. We unscrew the bolts holding the back panel, remove it, and then take out the cable itself. Then, using a multimeter, we “ring” the wires for breakdown. We immediately assess the condition of the terminals and contacts. Defective parts must be replaced.

Protective electrics of the machine

After making sure that the power cord is in good condition, you can proceed to checking the protective electronics of the washing machine. We are talking about a surge protector - the part through which the said cable passes. On some models, the filter also has a “barrel”, a protruding element that combines the wire and the “network connector”.

The primary diagnosis of a surge protector is carried out visually, as in the case of wiring. Then connect the multimeter. If the part does not pass the test, then repair will not help - you need to dismantle the device and purchase a new one.

Sometimes the plugs come out when the connection between the cord and the filter is broken. The detached contacts burn out, which leads to current leakage, short circuit and tripping of the RCD. In this case, stripping the cores is not practiced - only replacing the entire “network node”, including the wiring. Otherwise, the situation will repeat itself, new failures and overloads will arise.

The surge protector cannot be repaired - the broken part must be replaced.

Leads to emergency shutdown of the RCD and “sticking” of the keys on the dashboard. During operation, the contacts on the buttons are erased, when pressed, current leaks, the network is overloaded and the machine is triggered. In this case, we proceed like this:

- partially disassemble the top of the case to remove the dashboard;

- We ring the button contacts one by one with a multimeter.

First of all, it is recommended to check the recently used buttons. Most often on Bosch machines this is the “Start/Pause” key. The next most common sticking conditions are “Spin” and “Rinse”.

Electronics or power wiring

If everything is in order with the surge protector and the buttons on the dashboard, then you should “ring” the remaining wire connections of the washer. Since the control unit is already being studied, it is worth continuing the inspection from there. We act sequentially: apply multimeter probes to each terminal. First of all, we pay attention to suspicious elements, frayed, burnt or loose.

For a comprehensive diagnosis of the control board, special equipment is required, so it is better to turn to professionals.

When diagnosing the control board, it is better to do only a visual inspection. Any careless action can lead to irreparable consequences, including the “fatal outcome” of the equipment. Comprehensive testing of the module should only be carried out by professionals using special equipment.

The reason for the traffic jams may not be in the board. Therefore, we take a tester and use it to call the wiring connected to the electric motor, pump, heating element, pressure switch and other sensors and devices. All burnt elements encountered must be replaced, even if their performance is confirmed by a multimeter.

The motor or heating element is to blame

Often the RCD is turned off due to a faulty heating element. Washing heaters often fail, since most Russians have to put up with hard water. Heavy impurities and substances present in the liquid settle on the “spiral” in a thick layer of scale, which interferes with normal heat transfer and leads to damage to the heating element.

Sometimes the heater breaks down due to a faulty pump. This happens if the drain pump does not turn off and pumps water out of the drum without stopping. The control board loses contact with the device, obeys the pressure switch signals and gives the command to fill the tank. It turns out that cold water enters the machine, which does not have time to heat up - as evidenced by the temperature sensor. The module detects the absence of heating and forces the heating element to constantly work. The heating element cannot function without a “break” - it overheats, exhausts its life and fails.

Diagnostics and repair of heating elements proceed as follows:

- take a multimeter and set the value to 200;

- remove the back panel of the case;

- remove the drive belt (if the machine has a belt drive);

- we find the heating element located under the drum;

- we attach the multimeter probes to the contacts of the heating element;

- evaluate the result (normally the resistance is 15-45 Ohms, if more or less, replacement is needed).

A faulty heating element can be easily removed: two retaining bolts are unscrewed, the heater swings and is removed from its seat. The main thing is to purchase a replacement spare part that matches the serial number. Otherwise, the part will not “fit” or will quickly break.

When repairing Bosch washing machines, you must use only original spare parts!

Also, a Bosch machine knocks out the automatic machine if the engine is faulty. However, it is difficult to diagnose and repair the motor at home. It is much safer, cheaper and more reliable to immediately contact a service center for professional help.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment