Ardo washing machine does not spin the drum

It happens that after loading things into the washing machine and starting the desired mode, the user notices that the Ardo machine does not spin the drum. It seems that the cycle begins, water is poured into the tank, but the “centrifuge” remains in place or the rotation stops in the middle of the program. Let's figure out why the machine stops unplanned and how to return the equipment to working capacity.

It happens that after loading things into the washing machine and starting the desired mode, the user notices that the Ardo machine does not spin the drum. It seems that the cycle begins, water is poured into the tank, but the “centrifuge” remains in place or the rotation stops in the middle of the program. Let's figure out why the machine stops unplanned and how to return the equipment to working capacity.

Urgent measures

What to do in a situation when the automatic machine does not rotate the drum? First, you need to turn off the power to the equipment - turn off the washing machine and unplug the power cord from the outlet. Then you should prepare to drain the water from the tank. The soapy liquid will have to be drained through a garbage filter. Prepare a shallow but capacious container, place it under the body of the machine, unscrew the “plug” and collect the water in a basin. It is better to cover the floor around the unit with dry rags. When the water has been “pumped out”, you can open the hatch door and remove the laundry from the drum. Next, proceed to check the “home assistant”.

It is important to understand at what stage of the wash the machine stopped turning the drum.

If the laundry is clean, without soap stains, but just wet, it means that the drum is “stuck” at the spinning stage. When things are damp and powdery, it can be assumed that the wash stopped at the beginning or middle of the cycle.

Try spinning the drum by hand. If it rotates without problems, then the problem is in the electronics or the drive mechanism. When it is impossible to move the container from its place even manually, one can suspect that a foreign object is stuck between it and the tank, blocking the movement of the “centrifuge”.

Sometimes it's not a problem at all. The reason for the drum stopping during washing may be a simple overload of the automatic machine. If you cram too many things into it, the equipment will not cope with the load and will interrupt the cycle. Try dividing a load of laundry into two parts and washing each separately. Before making a final “verdict”, you should see if the hoses of the Ardo washing machine are pinched. Perhaps that is why the cycle has stopped. We will analyze the most likely reasons that the machine does not rotate the drum, and we will tell you how to fix the problem yourself.

Foreign body jams

Often, due to the carelessness of users, things that should not be there end up in the washing machine. For example, keys, hairpins, nails left in pockets, buttons torn from clothes, brooches, metal fasteners and much more. A foreign object stuck between the walls of the tank and the drum can easily block the rotation of the “centrifuge”.

An object stuck inside not only disrupts the operation of the equipment, but can also puncture the plastic tank. Then you will have to prepare for more expensive repairs. What to do in this situation? You'll have to take a flashlight and carefully inspect the drum. Light will also penetrate inside, through the porous surface, so it is quite possible to find a foreign object stuck between the walls. The foreign body should be pulled out carefully. Thin objects, such as a bra wire, can be reached through the holes in the drum. In other cases, in order to remove a stuck item, you will have to partially disassemble the Ardo case.

Let's get to the suspicious elements

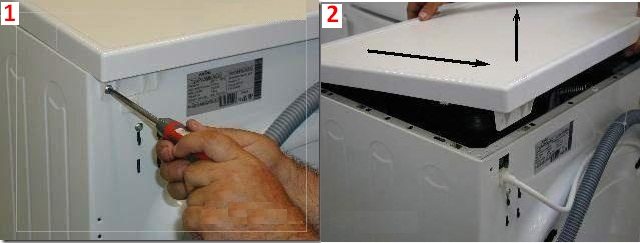

Removing items stuck between the tank and drum is not that difficult.You need to move the machine away from the wall to gain free access to the back panel. The further algorithm of actions will be as follows:

- Unscrew the bolts securing the top panel of the case;

- push the “lid” forward and remove it, put it to the side;

- unscrew the screws located around the perimeter of the rear wall;

- remove the back panel and set it aside so that it is out of the way;

- disconnect the wires from the heating element (before doing this, it is better to photograph the contact connection diagram so as not to make a mistake when reassembling);

- loosen the nut fixing the heater, “sink” the screw inward;

- remove the heating element from the “socket”.

You will get a hole where your hand can fit freely. It is through this that you can get inside the tank and remove stuck objects. Afterwards, all that remains is to reassemble the washing machine in reverse order.

Worn bearing unit

An emergency drum stop can be caused by broken bearings. Therefore, you will have to check the integrity of the bearing assembly. This work is quite labor-intensive; you need to be patient and have some free time.

Worn bearings “give out” themselves with a strong hum, noise and grinding noise that occurs when the washing machine is operating.

Usually, if the problem is with bearings, the machine begins to “complain” about the problem in advance. The machine vibrates strongly during operation, makes noise and buzzes. Such alarming “symptoms” indicate the need to replace components. To replace the bearings, you will have to remove the tank from the washing machine and disassemble it. During the repair process, you will need some tools: Phillips and slotted screwdrivers, pliers, wrenches, drill, small hammer, hacksaw, screwdriver.

First you need to remove from the machine all the elements that will interfere with removing the tank.We are talking about the heating element, motor, drive belt, pressure switch and drain pump. You will also need to disconnect the counterweight hidden under the top cover, remove the powder receptacle and the dispenser “hopper” itself. You will have to loosen the clamps and unhook the various pipes, remove the contacts and wiring, and disconnect the sensors.

It is recommended to take photographs during the process of disconnecting wires and parts so as not to make mistakes during subsequent assembly.

When all the “interfering” elements are dismantled, you can remove the plastic container from the case. Washing machines Ardo are equipped with non-separable tanks, which makes repairs difficult. The manufacturer assumes that when the bearings wear out, the entire tank will be replaced. However, this is quite expensive, so the craftsmen came up with a way out. Specialists successfully saw the container along the factory seam, and then connect the halves using moisture-resistant sealant and self-tapping screws.

Having gained access to the inside of the tank, all that remains is to “knock out” the old bearings and install new ones, not forgetting to replace the oil seal. All elements are generously treated with a special lubricant for washing machine parts. Next, all that remains is to “glue” the halves of the tank together with a special sealant. Additionally, you need to strengthen the structure with self-tapping screws. Assembling the automatic machine is carried out in the reverse order.

Drive element

Often the machine does not rotate the drum due to problems with the drive belt. The rubber band can stretch over time and begin to slip off the pulley. Sometimes it just breaks. It is better to immediately replace this part with a new one. Ardo washing machines with an asynchronous power motor usually have V-belts, and those with a commutator motor - poly V-belts.Components should be selected based not only on the engine type, but also on the model and serial number of the automatic machine.

To install a new drive belt, loosen the electric motor and move it slightly towards the drum. Next, the rubber band is put on the pulleys, after which the engine returns to its original position. You can use an adjusting screw to tighten the strap.

The tension of the drive belt should be strong, the norm when pressed is a drawdown of 4-5 mm.

The electric motor has failed

Another possible reason for the drum to suddenly stop is a motor breakdown. Over time, the motor brushes wear out and can no longer conduct current to the rotor winding. So, the engine stops working, and accordingly, the “centrifuge” does not spin up. The brushes of the commutator motors should be replaced every 3-5 years. Usually, it is during this time that the carbon rods wear out. It is necessary to select electric brushes designed for a specific engine model. Also, they always change in pairs, even if one rod is intact.

To check the condition of the electric brushes and, if necessary, replace them, you will have to remove the back panel of the case. Check that the machine is unplugged, then:

- remove the top panel by unscrewing a pair of bolts securing it (the cover moves to the rear wall);

- remove the back of the case by removing the screws securing the wall;

- remove the drive belt from the drum “wheel” and the engine pulley;

- find the engine, reset all wires connected to it;

- unscrew the fasteners holding the motor in the housing;

- remove the electric motor and lay it on its side, so that the place where the brush is inserted is at the top;

- deal with the fastening and pull the brush out of the motor housing.

After dismantling both electric brushes, inspect the commutator.If soot has formed on it, you should clean off the deposit with “zero” abrasive sandpaper or a hard eraser. Then you can insert new brushes into place. Having finished assembling the engine, you can install it back, securing it with bolts. Afterwards, the wiring is connected to the motor, the drive belt is pulled onto the pulley, and the housing is assembled. Next, you should check the equipment for performance by running a test wash.

The motors that Ardo machines are equipped with are very reliable, but there are still rare cases of winding short circuits or wire breaks. You can suspect such a breakdown if the washing machine works fine when idle, and when you start it in operating mode (with a full drum of things), the protection is activated and the electricity in the apartment is turned off. When the stator or rotor winding is short-circuited, the drum does not start to spin, and the washing machine makes a loud noise. Usually in this situation the engine can be repaired, but if there is a burning smell, the engine will have to be replaced with a new one.

You can check the electric motor using a multimeter. The tester measures the resistance on the lamellas. The discrepancy between readings should be no more than 5 ohms. You also need to test the winding. One multimeter probe is placed on the assembly, the second is applied to the stator. The maximum resistance value is considered the norm. When the winding is broken, the readings on the device screen will be close to zero.

Interesting:

1 reader comment

The Ardo tl1000x washing machine does not want to spin the drum, but the motor is running. In this case, the drive did not fly off.