Ardo washing machine fills with water but does not wash

From time to time, Ardo machines, especially those that have served for 2-3 years, begin to act up. Sometimes the equipment freezes, resets the settings, or forgets to spin. Often the washing machine turns on, fills with water, but does not wash - it remains standing with a full drum. If there are problems with dial-up, rebooting the system does not always help; you have to look for the causes of the failure and eliminate them. Let us consider in detail how to carry out diagnostics and repairs at home.

Frequent problems with Ardo

The Ardo washing machine can stop with a full tank at any time. This type of breakdown occurs both in newly purchased models and in machines that have already been used.. Problems with launching the program are caused by incorrect installation of equipment, impaired operating conditions and natural wear of parts. It all depends on the brand of the washing machine, the situation and the existing “symptoms”.

Modern Ardo washing machines are able to independently detect a breakdown thanks to a self-diagnosis system.

As a rule, braking before the start signals problems in four places:

- drive belt;

- electric motor;

- drum;

- control board.

It is almost impossible to immediately determine where the breakdown occurred. The only salvation will be a self-diagnosis system, which will automatically scan the nodes and narrow the search field with an error code. Without this function, you will have to act “blindly” - sequentially check every possible place of failure.

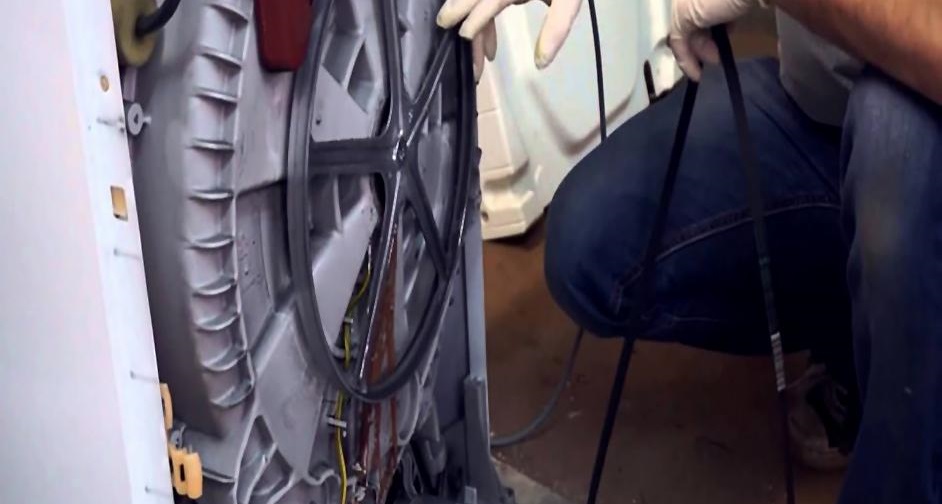

Drive mechanism broken

Problems with starting the Ardo washing machine after successfully drawing water are often caused by a faulty drive.More precisely, a drive belt that has flown off the pulley. Without its presence, the speed gained by the engine is not transmitted to the shaft: the drum remains motionless and the washing does not start. The main reason for belt failure is periodic overload of the drum. If you constantly load too much laundry into the machine, the elastic will wear out faster, tear and fall off. This can also be caused by natural wear and tear or manufacturing defects.

To confirm the “diagnosis”, you need to inspect the drive yourself. On frontal Ardos it is located at the back, and on vertical ones it is on the side. You can get to the belt by unscrewing the bolts holding the panel with a screwdriver or screwdriver. We remove the walls and pay attention to the pulley wheel. If it is empty, then the problem is in the elastic band.

A belt that has fallen off must be inspected for cracks, tears and stretches. If the elastic is torn or stretched, then replacement is indicated. The new “ring” is placed first on the engine pulley, and then on the drum. The main thing is to scroll the wheel from right to left until the rubber “sits” in the grooves.

Foreign body jammed in tank

The washing machine stops after drawing water and when the drum gets stuck. Probably, a foreign object got into the tank - a bra wire, a coin or keys - which “stood up awkwardly” and blocked the centrifuge. The engine tries to spin up, hums, but it is useless - the machine stops, the washing does not start. If you suspect a “spell”, you must:

- activate the “Drain” program;

- at the end of draining, disconnect the washing machine from the power supply;

- open the hatch door;

- try to spin the drum manually.

Before washing, check the pockets of items loaded into the drum!

If the drum stops, then the instructions for what to do next are simple: remove the top cover, tilt the machine back and remove the stuck object through the resulting gap. There is another way - remove the back panel, dismantle the heating element and, sticking your hand into the vacated hole, take out the “lost item”.

Engine lost power

If everything is in order with the drive and drum, then you will have to move on to more difficult units to diagnose and repair. The first of them is an electric motor. The logic is simple: if the washing machine does not accelerate after filling with water, it means the motor has failed.

The motor itself rarely breaks down. Typically the problem is:

- overheating;

- worn brushes;

- peeled lamellas.

First of all, we exclude the first option. Overheating of the motor is possible if the machine is turned on several times without stopping. No? Then we move on to inspecting the electric brushes.

- Unscrew the back wall from the Ardo case.

- We free the engine from the drive belt, connected wires and sensors.

- Loosen the bolts securing the motor.

- We take out the engine and find plastic cases on the sides of its body.

- Disconnect the terminals from the cases.

- We open the brushes, clamp the spring and take out the carbon rods.

Do not run several cycles in a row without stopping - the Ardo motor may overheat!

If the carbon tips are worn out and their length is less than 1.5-2 cm, then replacement is needed. Two similar brushes are purchased - the rods are always replaced in pairs, even if one of them is intact. When securing the new “coals”, we make sure that the ground end is positioned correctly. Peeled lamellas are “burrs”, peeled metal plates. To repair them, you need to clean the engine using fine sandpaper. We apply the paper to the body and carefully polish the surface.

The control module is to blame

It is extremely rare that problems with starting the Ardo washing machine result from a breakdown of the control board. The module may freeze, not receive information from the pressure switch about the end of the fill, or not transmit a command to turn on the engine. As a result, the washing machine will stand up with a full tank.

You should only doubt that the module is faulty after checking all other possible problems. But it is strongly not recommended to diagnose and repair the board yourself! Only a professional repairman should work on electronics, otherwise it is easy to aggravate the problem, even to the point of death. Only a specialist can ring each element of the block and make a decision about its condition.

If the washing machine fills with water but does not start washing, then the problem is in the motor, drive belt, drum or circuit board. Almost all possible breakdowns can be identified and repaired independently, with the only exception being the module – it should be checked by a specialist.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment