How to find out that the heating element in the washing machine has burned out and how to fix it?

Although the heating element is not considered the most vulnerable part in the washing machine, it has to be replaced approximately once every 2-3 years. They burn out due to inadequate quality of tap water, voltage surges and frequent launch of high-temperature cycles. How do you know when it’s time to install a new heating element? You can check the tubular heater with your own hands; even a “newbie” can handle this work. Let's figure out how to understand that the heating element in the washing machine has burned out, how to dismantle the old one and install a new element.

Although the heating element is not considered the most vulnerable part in the washing machine, it has to be replaced approximately once every 2-3 years. They burn out due to inadequate quality of tap water, voltage surges and frequent launch of high-temperature cycles. How do you know when it’s time to install a new heating element? You can check the tubular heater with your own hands; even a “newbie” can handle this work. Let's figure out how to understand that the heating element in the washing machine has burned out, how to dismantle the old one and install a new element.

How to understand that the heating element has failed?

It is not entirely easy for a “newbie” to find out that it is the tubular heater that has failed. Modern machines have a complex structure, and the lack of water heating may indicate not only a breakdown of the heating element, but also a malfunction of the temperature sensor, burnout of semiconductors or tracks on the control board. To accurately determine the problem, you will have to diagnose the washer. You can guess that a tubular heater is broken by a number of signs:

- The machine does not heat the water to the set degree. It is necessary to monitor how the machine works on a program, for example, “Cotton 60”. Periodically touch the sunroof glass - if it remains cold throughout the entire cycle, you may suspect a problem with the heating element;

- The washer displays a fault code a few minutes after the cycle starts. Modern automatic machines are equipped with a self-diagnosis system, and if an error appears on the display, immediately look at its explanation. Perhaps the unit just indicates a breakdown of the heating element;

- The automatic machine is electrocuted.A breakdown to the body is a very dangerous situation. When the tubular element is already in a “deplorable” state, it can pose a threat to the health of users. Therefore, if you feel a noticeable tingling sensation when touching the washing machine, immediately turn off the power to the equipment and start checking the internal parts;

- unpleasant odor coming from equipment. When powder or a foreign object that has fallen into the tank burns to the body of the tubular element, the heating element begins to smell disgusting. This symptom may also indicate a problem with the heater;

- a thick layer of plaque on parts. If, after removing the heater from the housing, you find that it looks “unpresentable” - covered with scale and has traces of carbon deposits, you should not delay replacement. However, first test the heating element with a multimeter - if it is in order, a thorough cleaning of the element will help.

If you notice one of the described signs, it is better to immediately check the heating element. Still, it fails more often than a temperature sensor or control module. We’ll look at what to do and where to look for the heating element in an automatic machine in more detail.

We buy a replacement part

You can repair a washing machine whose heating element has burned out yourself, without turning to a specialist for help. The work does not require special skills and abilities - you just need to be patient and strictly follow the instructions for action. To diagnose a tubular heater, you will need a multimeter.

To dismantle the heating element, you will need a standard set of tools: a screwdriver, a screwdriver and a 10mm socket.

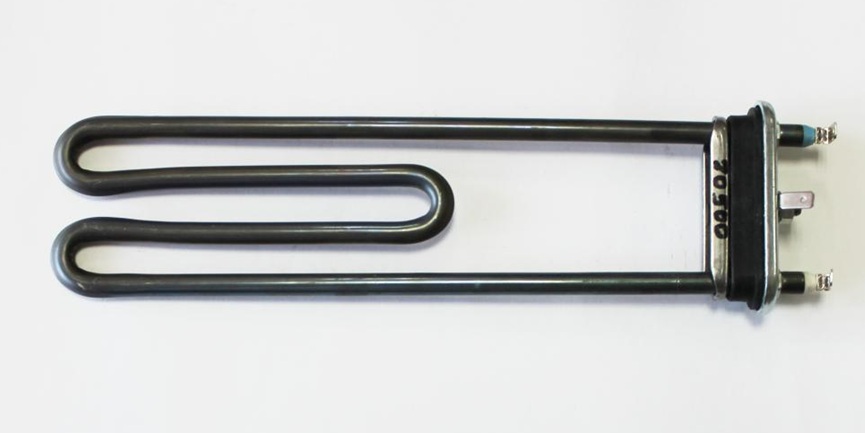

It is important to purchase a suitable replacement heating element. The ideal option is to remove the “factory” part from the machine and go to the store with it. In any case, when purchasing a heater you need to consider:

- markings applied to the body of the old heating element;

- model and serial number of the automatic machine;

- tubular heater power. In modern washing machines, in most cases, heating elements with a rating of 1800-2000 watts are installed.

Usually there are no problems with purchasing a new tubular heater. A device with the necessary parameters can be purchased on the Internet or in a specialized store. Another option is to contact the service center, the staff will help you order a suitable replacement part.

We make a replacement

There are several reasons why heating elements quickly fail. First of all, it is hard water. The impurities contained in it settle on the tubular heater, disrupting its thermal conductivity. Power surges and frequent launch of high-temperature washing programs also lead to breakdowns.

To check and, if necessary, replace the heating element, you will have to partially disassemble the machine body. Some front-facing models have a heater installed in front of the tank. In this case, you need to remove the top and front panels of the case. For “vertical” units, the element is located on the side - it will be enough to remove the left or right wall.

In most front-loading washing machines, the heating element is located in the rear of the tank. To access it, you just need to remove the back panel or open the technical hatch (depending on the machine model). You may also need to remove the drive belt from the pulley.

You should work carefully - be sure to turn off the power to the washing equipment and turn off the tap responsible for the water supply.

Further actions will be as follows:

- move the machine away from the wall, inspect its back wall;

- Using a screwdriver, unscrew all the bolts around the perimeter of the service hatch. You can also do this with a regular screwdriver;

- remove the rear “technical” panel;

- find the heating element - it is located on the left side, immediately under the tank of the automatic machine;

- take a photo of the wiring diagram for the heater;

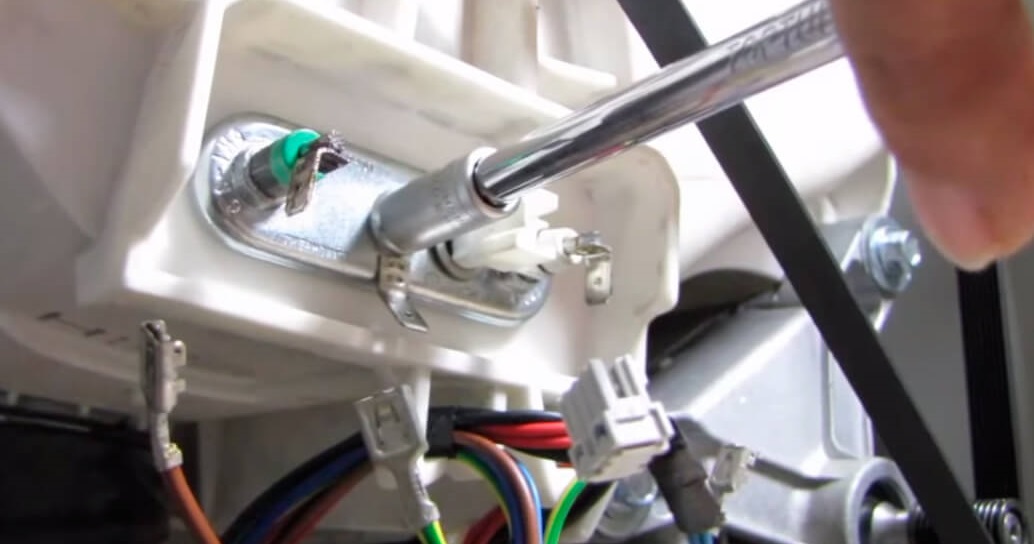

- disconnect all wires and power terminals from the heating element;

- unhook the temperature sensor chip from the heater;

- using a 10mm socket, unscrew the nut securing the part;

- press the central bolt inward so that it “falls” in there;

- grab the heating element and, using gentle, rocking movements, remove the heating element from the “socket”.

If the heating element “tightly” comes out of the “socket”, pour a little dishwashing liquid into the gap. Due to this, the sliding of the rubber seal will improve and it will be easier to pull out the heater.

After cleaning the seat, you can install a new tubular heater. It is secured in the machine with the same nut. It is important not to tighten the fasteners too much, otherwise the cuff of the heating element may become deformed. After this, all the removed terminals are connected to the part. It is better to focus on the photo you took so as not to confuse anything. Next, all that remains is to put back the service hatch panel, secure it with self-tapping screws and run a high-temperature washing program to check the machine.

You can find out whether the dismantled heating element is really broken using a multimeter. It is necessary to switch the tester to ohmmeter mode and attach the probes of the device to the heater contacts. A working element with a power of 1.8-1.9 kW should produce a resistance within 25-30 Ohms.

If the multimeter screen displays zero, one or an infinitely large number, the heating element will have to be replaced. The heater cannot be repaired, so you need to buy a new spare part. When the part shows resistance within the normal range, check it for breakdown.Switch the multimeter to buzzer mode and attach the first probe to the heating element terminal, the second to the element body. A “squeaking” tester will indicate a malfunction of the tubular heater.

Interesting:

4 reader comments

Thank you. Very useful information.

thanks for the advice

What if a sediment in the form of sand-like particles appears on your laundry after washing? Is this a broken heating element (burnt out)?

I had this happen from a powder with a “moid hole” painted on it. I replaced the powder with another - the sand disappeared.