What can be done from an old washing machine

The time comes when the “home assistant” that has served you faithfully for many years breaks down, and it is no longer practical to repair it. There is a need to buy a new washing machine, but what to do with the old one? You can take it to the trash heap, but this will be the act of an uneconomical, impractical person, because there are so many useful things hidden in the washing machine that can serve you well. Let's talk about the use of the engine and other parts of the washing machine in the household. We hope you will change your mind about throwing away your old machine.

The time comes when the “home assistant” that has served you faithfully for many years breaks down, and it is no longer practical to repair it. There is a need to buy a new washing machine, but what to do with the old one? You can take it to the trash heap, but this will be the act of an uneconomical, impractical person, because there are so many useful things hidden in the washing machine that can serve you well. Let's talk about the use of the engine and other parts of the washing machine in the household. We hope you will change your mind about throwing away your old machine.

What machine parts can be used?

Everyone knows that an automatic washing machine is a complex household appliance, consisting of a fairly large number of elements, and the more modern the automatic machine, the more parts it contains. About, how does an automatic washing machine work? can be read in one of the articles on our website. If you conduct a survey of people on the street, you will probably find that every tenth person has an old washing machine in their garage, barn, or dacha, which seems a pity to throw away, but at the same time they don’t know what to do with it. What parts of an old washing machine can be used for business?

- Email engine. If the old washing machine has electric. engine, then this is a treasure in itself. Carefully remove it from the case, disconnecting all the wires, wipe it, wrap it in a cloth and put it in a safe place.

- Drum. The drum of the automatic washing machine is made of high-quality stainless steel; it has a lot of uses, so it also needs to be removed from the body and stored.

- Manhole cover.This is also quite a useful thing, and not only the lid itself is useful, but also its parts.

- Legs, clamps, hoses, el. wiring. All this can be useful anywhere.

- Springs and counterweights. Springs on washing machines play the role of shock absorbers, they are very powerful, and counterweights are good because they are heavy but compact - we leave both.

- Washing machine body. After removing everything useful, return the walls of the machine to their place; the body itself can also be useful.

Important! If you are no stranger to working with electronics, you can leave the control unit. There are a lot of semiconductor elements on the control board that can be used to repair electrical appliances and to make useful gizmos for the household.

Why use the machine's engine and how to connect it?

Work email The engine from an automatic or semi-automatic washing machine can become the basis for much-needed household appliances. The most common application is el. emery for sharpening knives, tools, drills and other things. Making such emery is not very easy, but it is still possible. The first and main problem is how to secure the whetstone to the motor shaft.

The diameter of the grindstone hole, as a rule, does not correspond to the diameter of the electric shaft. motor from a washing machine. This means it is necessary to make a flange that would be pressed onto the shaft on one side and have a thread on the other so that the grinding wheel could be fitted and secured. Professional craftsmen recommend using a 32 mm piece of steel pipe as a flange. What are we doing?

- We take a piece of 32 mm steel pipe. The length of the cutting should be 15-20 cm; a very long one will not work.

- At one end of the pipe cut, a thread must be cut; the length of the thread must be at least 2 times the thickness of the grinding wheel.

Very important! The thread must be cut in the opposite direction of rotation of the electric shaft. engine. In other words, if the electric shaft The engine rotates clockwise, which means we make the thread counterclockwise, otherwise the whetstone will fly off.

- We heat the other end of the pipe cut with a blowtorch and press it onto the shaft; after the pipe has cooled, it will be firmly connected to the shaft. To strengthen the connection, you can use a drill to drill across the junction of the pipe and the engine shaft and screw a bolt into the hole and tighten it with a nut. If there is welding, then you can use it to attach the flange to the shaft - it will be ideal.

- Now we take three nuts of suitable size and two corresponding washers. Screw the first nut onto the flange until it stops until the thread runs out. Next we put on the washer, then the grinding wheel, then the washer and nut again. We tighten everything well and tighten the locknut at the end.

The main thing is done, now our task is to secure the engine as securely as possible. Look at what holes for fasteners are on the el. engine, everything is individual here, based on this, make a stand. The simplest thing is to twist the stand from small corners, and then secure the emery to the workbench.

Note! To install the engine on a workbench, you can use a bracket from a washing machine; some automatic machines have good mounts that can be used.

Another important stage of work on the production of emery is connecting the electrical connection. engine to the electrical network. Let's consider the simplest option.

Another important stage of work on the production of emery is connecting the electrical connection. engine to the electrical network. Let's consider the simplest option.

- We take a multimeter and check the wiring and terminals of the motor.

- We need the output of the working winding. To detect it, you need to measure the resistance; if the device on one of the terminals shows a value close to 12 ohms, then this is the working terminal.

- We connect the working output to the mains (220V).

- Without a starting device, our emery will not start even after we have connected it to the network, therefore, in order for the emery to start rotating, it must be turned with force by hand. Act carefully and your hand will replace the trigger.

There are other options for using an electric motor from a washing machine, but the principle of application is exactly the same. It is installed on small homemade grain crushers and grass shredders, household concrete mixers, and even on small sawmills. We will not describe the nuances of manufacturing each electrical appliance; draw analogies yourself.

How to use the drum?

A stainless steel drum is a great, durable piece that can be used to create a lot of things. What homemade products can you make with your own hands based on the drum of a washing machine? On the Internet you can find a lot of videos about how people make barbecue roasters and kebab makers out of a drum. Indeed, the thing is magnificent, and it costs nothing to make it.

- We remove the drum from the washing machine body along with the pulley and shaft.

- We place the drum directly on the wheel with the hatch up, and here you have an improvised brazier.

- You can use a grinder to cut off the front part of the tank (near the hatch) to expand the working part of the fryer. It will also be convenient to put firewood in it.

For your information! The drum barbecue turns out great, because the drum is dotted with a huge number of small holes through which air evenly flows to the coals, fanning them and providing the necessary heat.

There are also a lot of videos online on how to make a small smokehouse out of a drum. A very interesting and practical option for using a drum, which we tried ourselves and would be happy to share our experience. How is a smokehouse made?

- We take a huge iron pan. The main thing is that the drum of the washing machine fits completely into the pan. You can also take an iron tank from a “Riga” or “Siberia” washing machine; a drum from an LG, Ariston or Indesit washing machine fits perfectly into it.

- To prevent the drum from lying on the bottom of the tank of the machine or pan, we will make a wire stand in the form of a lattice with legs. It will raise the tank inside the pan and make it possible to place smoldering fuel below.

- We also make a round grill out of wire, slightly larger than the diameter of the washing machine drum. We make 10-15 hooks on the grill, on which we hang meat, lard, fish, vegetables or cheese, everything that requires hot smoking.

- Place the tank or pan on a flat area outside, away from flammable objects.

- We put several smoldering coals from the fire at the bottom of the tank or pan, fill the coals with a small amount of alder or birch chips and fan it all so that smoke comes out.

- Place the wire stand directly on the smoldering wood chips.

- Place the drum in the pan on the stand with the hatch facing up. We place a grate on top of the drum, and hang the products that need to be smoked on hooks inside the drum.

- We close the tank or pan with a lid or sheet of metal, and press it down with something heavy on top. We wait until the food is smoked; along the way, you can add wood chips to the tank to provide the required amount of smoke, that’s all.

Craftsmen also make poufs and futuristic lampshades for chandeliers from washing machine drums. The pouf is easy to make. We take a pillow, cut out a square from chipboard that matches the size of the pillow. We nail the pillow to the chipboard with a furniture stapler. Next, we take a simple card loop, screw it on one side to the chipboard with a cushion, and on the other to the top of the drum wall. We got a pouf with a hinged lid, and inside the pouf you can store small things.

You can decorate the pouf by painting the outer walls of the drum. There are many options on how to do this in photos and videos on the Internet. You can also not bother and cover the outer frame of the pouf with a beautiful fabric.

For your information! Washing machine drum poufs are quite durable and will last you for many years.

To make a futuristic lampshade for a children's room, you need to do the following:

- from a large piece of textolite (or other non-flammable material that does not conduct electricity) we cut a circle to the size of the drum hatch;

- use a grinder to cut off the bottom of the drum;

- cut out a hole for the cartridge and hook in a circle of textolite;

- insert the cartridge into the PCB circle and hang it on a hook;

- securely fasten the PCB circle to the drum with bolts so that the circle completely covers the hatch;

- the drum with the socket hangs from the ceiling, now we screw in the light bulb (through the pre-cut bottom of the drum) and admire the result of the work.

What kind of homemade products do people make from the drum of a washing machine with their own hands? We have listed and described only a small part. The drum is used as a container for washing mushrooms and fruits grown in the garden. It’s very convenient: you put vegetables in the drum, pour water from a hose through the hatch, and the water along with the dirt pours out through the holes. The resulting vegetables or mushrooms are clean.

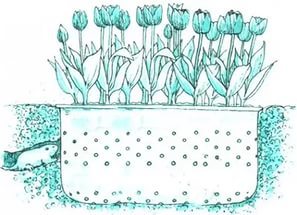

The drum can also be used as a container for seedlings or a growth limiter for shrubs and perennials. It’s clear with seedlings, we won’t explain it, but let’s talk about the limiter in more detail. Some shrub plants that summer residents like to plant on their property tend to grow in breadth (raspberry, honeysuckle, euonymus). So, if you pour black soil into a drum from a washing machine, and plant, for example, a raspberry bush in it, then bury the drum in the ground, the raspberries cannot spread across the area.

There are other options for using a washing machine drum. The main thing is to use your imagination, don’t be lazy to do something with your own hands, and perhaps you will become one of the authors of a new homemade product, created from the drum of a used washing machine.

How to use the hatch door?

We have seen that a lot can be done from the motor and drum of a washing machine, but how to use the rest of the parts, for example the hatch door. Nothing could be simpler. The hatch door of a top-loading washing machine is very durable and can be easily removed. It can be used in a variety of ways.

- Install a box covering riser pipes and water meters onto the technical opening. This is very convenient, because through the transparent window of the hatch door you can view and rewrite meter readings. If you need to turn off the water, the hatch door opens quickly and conveniently and does not interfere with access to communications.

- Some people dismantle the hatch and pull out the convex glass from the frame, which can be used as a bowl for feeding pets.

- Some people install a manhole cover on their dog kennel. In this case, you will have to install not only a lid, but also a lock from the washing machine into the booth. It won’t block, but it’s enough to keep the dog locked in the kennel.

- One of the active members of the forum suggested installing a manhole cover on the window of the steam room of the bathhouse. True, you will first have to cut a round window just to the size of the hatch cover, but it will be easy to close and open. Just don’t forget to paint over the glass of the hatch cover, just in case.

Important! The difficulty of installing a hatch cover on a booth or steam room window with your own hands is to correctly install the lock so that the fixing hook fits tightly.

Legs, clamps, counterweights and other useful little things

What homemade products can use the legs of a washing machine? The good thing about the legs of the washing machine is that they are very durable and can be adjusted in height. Screw them to a heavy piece of furniture, such as a wardrobe, and you can make it taller or lower. If you screw the legs from the washing machine to the workbench, you can adjust its height, which will make work more convenient.

Clamps and wiring can be used in the process of repairing electrical appliances with your own hands. Those who are no stranger to working with a multimeter and a soldering iron will definitely find this little thing useful. Counterweights can also be used. In old washing machines, counterweights were made mainly of cast iron; they can be scrapped, but they can also be used on the farm. For example, in order to press down a container with cabbage during pickling, by the way, a concrete counterweight is suitable for this purpose; it is quite small and quite heavy.

Clamps and wiring can be used in the process of repairing electrical appliances with your own hands. Those who are no stranger to working with a multimeter and a soldering iron will definitely find this little thing useful. Counterweights can also be used. In old washing machines, counterweights were made mainly of cast iron; they can be scrapped, but they can also be used on the farm. For example, in order to press down a container with cabbage during pickling, by the way, a concrete counterweight is suitable for this purpose; it is quite small and quite heavy.

To summarize, we note that it turns out that some parts of an “outdated” washing machine can be used to create things needed in the household. This applies not only to the motor, but also to the drum, hatch, wiring, clamps, counterweights, and the body itself. If you have the time and desire to give parts of an old washing machine a second life, do it, the effort you expended will pay off.

Interesting:

4 reader comments

Just add about connecting the engine from the machine, automatic and beautiful... otherwise the Indesites and Zanussi are already dismantling the organs, but there’s nothing sensible about the engines... I don’t know, at such speeds, it makes sense for me to install an abrasive or it will fly away.

If it flies away, you need to use at least the drum pulley through the belt, but this is not relevant for sandpaper.

There are a lot of proposals on the Internet regarding an engine speed control board without loss of power on a TDA 1085 chip and a seven-stor. Order, install and you will be happy.

I made a lawnmower out of the engine, it's a thing!