Bosch washing machine control module repair

If you do not have experience working with electronics, then it is better to entrust the repair of the control board of a Bosch washing machine to specialists. The module consists of dozens of semiconductors, tracks and microcircuits. Without understanding the unit's design, you can damage the controller even more. Once you have some knowledge, you can diagnose and repair the element yourself. We'll tell you how to do this.

If you do not have experience working with electronics, then it is better to entrust the repair of the control board of a Bosch washing machine to specialists. The module consists of dozens of semiconductors, tracks and microcircuits. Without understanding the unit's design, you can damage the controller even more. Once you have some knowledge, you can diagnose and repair the element yourself. We'll tell you how to do this.

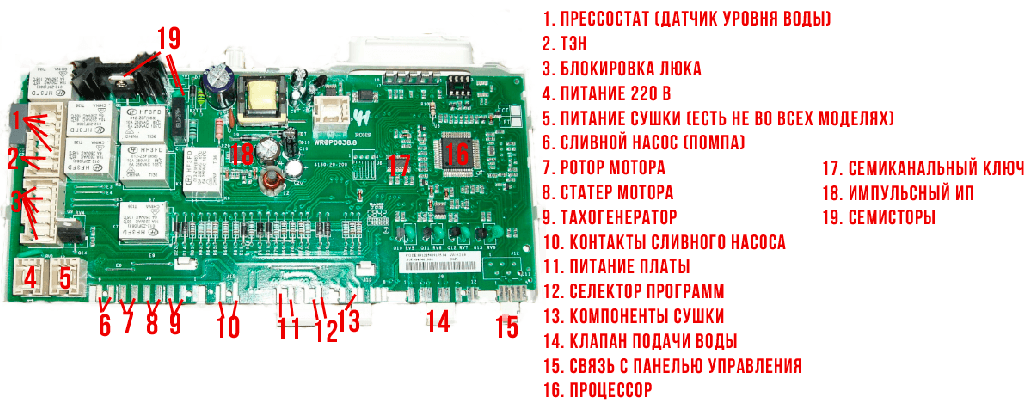

Elements of the control and indication board SM Bosch

Problems with the main control unit in Bosch washing machines rarely occur. The board often burns out precisely because of external influences - moisture on the semiconductors or power surges. The module controls the entire operation of the washing machine, so if it is damaged, the SMA cannot function normally.

In some cases, Bosch washing machines themselves indicate a problem with the unit by displaying the corresponding error code on the display.

It is easy to dismantle the control unit. It is enough to pull out the powder receptacle, remove the top cover of the machine and the dashboard, reset the wiring and unscrew the bolts securing the board. Now we’ll tell you what parts the “brain” of Bosch SMA consists of.

The controller of most Bosch AMCs consists of a main unit and an indication unit. They are connected. Each element is responsible for specific functions. On the main board there are:

- program selector;

- power unit;

- capacitors;

- HF transformer;

- rectifier diodes;

- varistor;

- triacs (each controls the operation of different elements of the washing machine: drain pump, hatch blocking device, fill valves, etc.);

- Voltage regulator;

- resistor;

- microcontroller;

- thyristor block;

- motor control triac;

- relays responsible for reversing the engine and turning on the heating element.

The indication board is connected to the main unit with a special cable. It contains:

- LEDs;

- touch button antennas;

- high-frequency NPN transistors;

- microcircuits for indicators;

- driver that controls the operation of LEDs;

- Voltage regulator;

- capacitors;

- microcontroller;

- buzzer (a device that makes a sound when the washing machine is turned on and at the end of the cycle).

The electronic unit is the “brain” of the washing machine. It controls the execution of any washing programs. Bosch washing machine modules consist of one or two boards - this depends on the SMA model. On each part there are semiconductors responsible for the operation of different components of the machine. The elements are connected to each other by paths.

If the electronic unit is damaged, the machine may not turn on at all or may not respond to user commands, or “freeze” at a certain stage of the cycle. If all other possible breakdowns are excluded, you will have to check the functionality of the control board. We'll tell you how diagnostics are performed.

Checking control board elements

The Bosch SMA electronic unit usually fails due to voltage surges in the network. Therefore, if the light in the apartment was flashing, and after that the machine stopped turning on, most likely the board burned out. Another possible reason is increased humidity in the room and water getting on the semiconductors.

The first stage of diagnosis is a visual inspection of the board for scorch marks.

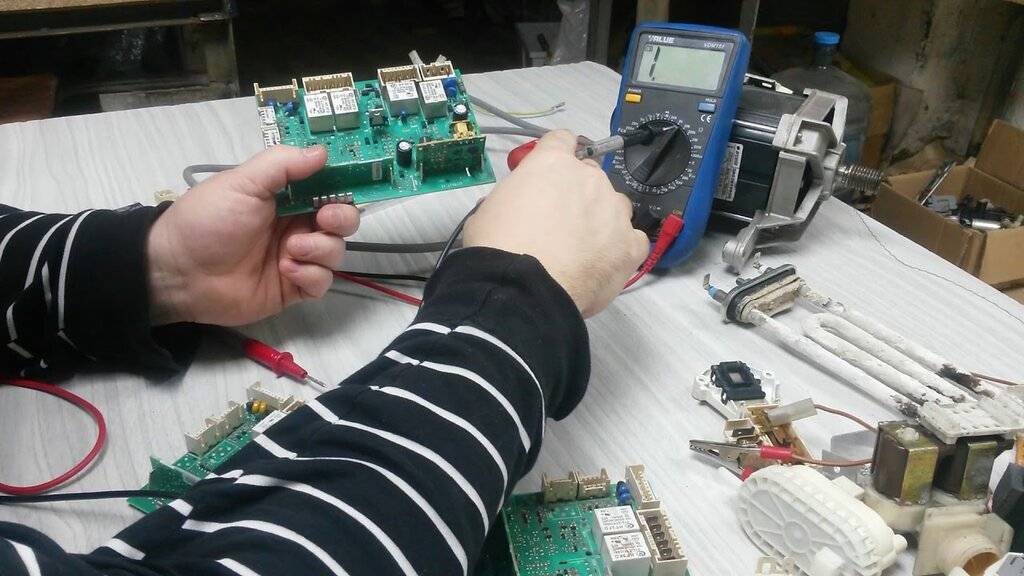

If the board looks clean, there are no burnt areas or black spots on it, you will have to ring each semiconductor. Diagnostics of the control unit is performed with a multimeter. The tester is switched to the “dialing” mode.

After the switching power supply, there is a smoothing capacitor on the main module. The terminals of this capacitor must be connected to the contacts of the connectors going to the indication board. If the multimeter makes a squeak, it means that both parts are “communicating” with each other.

Capacitors on the control board are responsible for voltage stabilization. The obvious cause of element malfunction is its swelling. The capacitor contacts are also tested with a multimeter. A one on the tester screen will indicate a break, a zero - a short circuit.

The next stage of diagnostics is checking the contacts coming to the display board from the main unit. You need to find a white element with five pins on it. The first is “minus”, the third is “plus”.

Nearby, on the display board, there are two diagnostic contacts. It is needed just to check the power at the connectors. One multimeter probe is applied to the “minus”, the second to the diagnostic terminal. We do the same with the “plus”.

If the multimeter beeps, it means there is contact. In the event of a break in the circuit, the tester will remain silent. When the elements do not communicate, the signal does not go to the voltage stabilizer, and, therefore, power does not go to either the microcontroller or the logic assembly. Because of this, the unit cannot function normally.

Also, using a multimeter, the voltage between semiconductors is measured. For example, normally, the stabilizer should “produce” 9 Volts. Check whether the actual value matches the declared value. If not, you will have to clean the contacts or completely replace the element.

After diagnosing the capacitors, the thyristor block is checked. It is necessary to set the negative resistance and ring the first order diodes with a multimeter.The voltage indicator should not exceed 20 Volts.

In a similar way, all contacts on the control board are called one by one. If the multimeter is “silent”, then there is no connection between the semiconductor elements. This way you will know what parts of the block to pay attention to.

Troubleshooting

Undoubtedly, the most difficult stage is diagnosing the control unit of a Bosch washing machine. The most difficult thing is to detect a fault, it is easier to repair the board, all spare parts can be bought. Module repair will consist of soldering tracks, cleaning contacts, and replacing damaged semiconductors.

In the vast majority of cases, a soldering iron is needed to repair the SMA control board.

In addition to the soldering iron, to repair the main electronic unit of the Bosch CMA you will need:

- rosin;

- tin;

- solder;

- sharp knife (for cleaning oxidized contacts).

If you have no experience working with electronic devices, it is better not to try to repair the controller yourself. You can only aggravate the situation and further damage the board. Then you will need to change the entire part, and this is much more expensive than installing new semiconductors or soldering tracks.

Having completed the repair, be sure to do a final test of the unit. The test is performed with a multimeter. If all semiconductors dial normally, you can put the board in place and start the automatic machine.

If after repair the problems remain, then the problem may be in the software part. In this case, you will need to update the controller firmware. To carry out the work you will need an adapter (programmer) and special drivers. It’s better to take the board to a service center, and there the technicians will load the software directly into the processor.

There are cases when the Bosch CMA controller cannot be repaired.And if the service center confirms your guess, the unit will have to be replaced. You can order a new board specifically for your washing machine model in specialized online stores.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment