Whirlpool washing machine pump repair

The pump of the automatic machine constantly experiences heavy loads, pumping waste water from the tank into the sewer. The part is subject to heavy wear and tear and may fail over time. Is it possible to repair a Whirlpool washing machine pump? How to check and repair an element? Let's look into the nuances.

The pump of the automatic machine constantly experiences heavy loads, pumping waste water from the tank into the sewer. The part is subject to heavy wear and tear and may fail over time. Is it possible to repair a Whirlpool washing machine pump? How to check and repair an element? Let's look into the nuances.

Does the pump need repairing?

A broken pump is not always the cause of a non-functioning drain. There may be other problems with the drainage system. Therefore, before repairing or replacing the pump, consistently check all the “sore points” of the Whirlpool washing machines.

- Clean the garbage filter. Often the machine cannot drain water from the tank precisely because the filter element is clogged. The “trash bin” is located in the lower corner of the Whirlpool SMA, behind a decorative panel or a special hatch. Unscrew the spiral, clean it and the resulting hole from debris and dirt. You can often find coins, buttons and even socks inside. After removing foreign objects, put the plastic part back and run the test cycle.

- Inspect the drain hose. Perhaps the corrugation is bent or a blockage has formed inside. Carefully feel the tube, or better yet, disconnect it from the washing machine body and from the connection point to the sewer, then rinse under running warm water. Then run a test drain. If the machine continues to act up, the diagnostics will have to be continued.

- Check the impeller stroke. To do this, unscrew the garbage filter and look into the resulting hole. The impeller will be visible there. Check to see if there is a foreign object stuck between the blades. Also remove any tangled threads and hair from them.Scroll the part with your fingers - it should rotate freely. If movement is not difficult, most likely the problem is with the pump itself.

Before repairing the Whirlpool washing machine pump, check whether the garbage filter and drain hose are clogged, and whether the rotation of the impeller is blocked.

You can tell if the drain pump is OK by listening to its operation. Therefore, start the wash and analyze the sounds made by the Whirlpool machine. If at the draining stage the washing machine starts to make a loud noise, but the water does not go down the drain, we can talk about a pump malfunction. Complete silence will also indicate a breakdown, since measured and implicit noise should still be present.

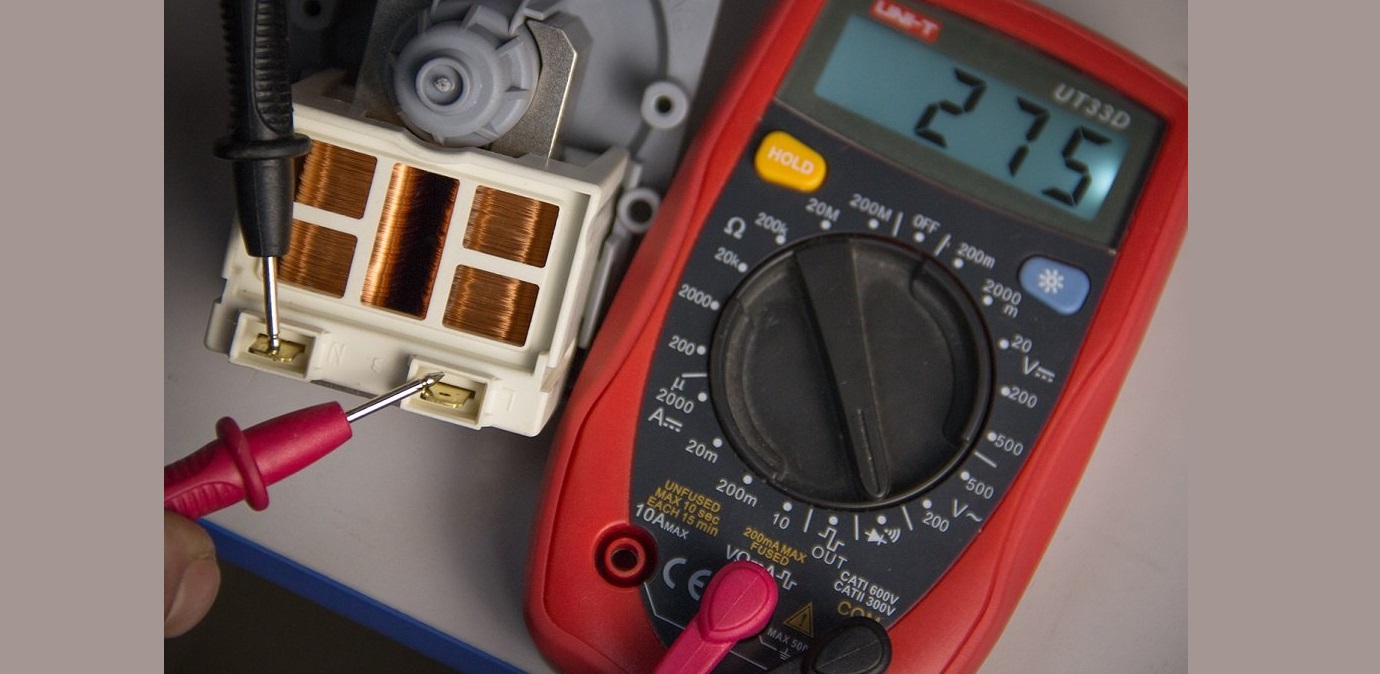

To diagnose the pump you will need a multimeter. It can be used to test the integrity of the stator winding of a part. The contacts and sensors of the pump are visually checked - they should not show any signs of damage.

Also, the reason for the missing drain may be in the SMA control board. However, the electronic module fails extremely rarely, so most likely you will have to replace the drain pump of the automatic machine. Let's figure out how to repair the washing machine.

“Consumables” for pump repair

No special tools are required when repairing or replacing the washing machine pump. It will be enough to “arm yourself” with a regular Phillips screwdriver. A penknife may also come in handy; it is better to have it on hand.

To diagnose the pump you will need a multimeter. The device can be purchased at hardware stores or ordered online. The tester is inexpensive, there are models for $2-4.

The number of components for repairing the Whirlpool SMA directly depends on the scale of the breakdown. In the worst case, you will have to purchase:

- pump;

- impeller;

- pump sensor;

- seal;

- contacts;

- axis;

- gasket;

- pulley.

As already mentioned, this is a set of spare parts for the worst case scenario of pump failure. In most cases, simply purchasing a new pump is enough. How to select replacement components?

When purchasing spare parts, be guided by the Whirlpool CMA model and the serial number of the device.

You can also dismantle the broken pump and go to the store with it. The seller, based on the marking of the part, will select a similar one. When ordering a pump on the Internet, check all the information yourself to buy the components suitable for your Whirlpool model.

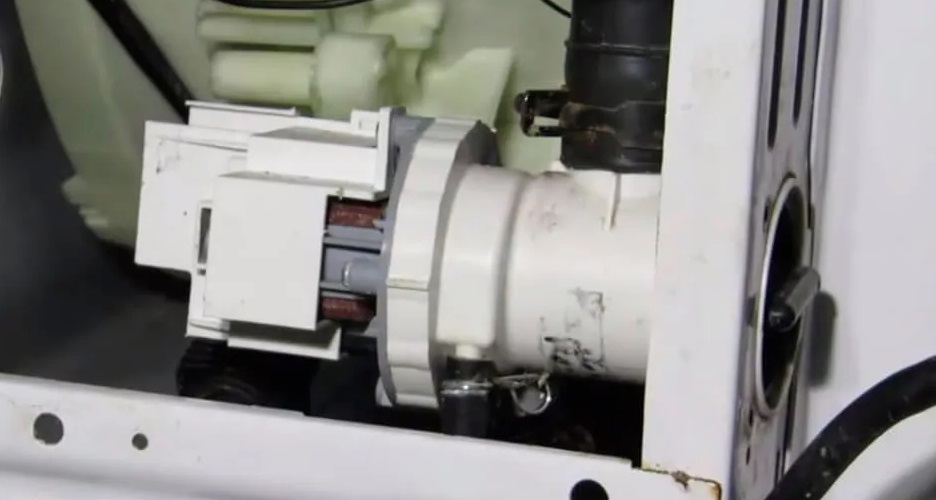

Getting to the pump

The pump on all Whirlpool models is located in one place - in the lower part of the case. Regardless of whether it is a direct drive or belt drive model. To get to the pump, you don’t even have to disassemble the washing machine. Enough:

- de-energize the automatic machine;

- close the shut-off valve;

- disconnect the device from the water supply and sewerage;

- drain the remaining water from the system by unscrewing the garbage filter;

- cover the floor with a blanket;

- lay the washing machine on its left side, on a soft substrate;

- remove the pan (if equipped).

Be sure to take into account that when you unscrew the garbage filter, water will flow out of the hole. Therefore, cover the floor in this place with rags, or place a low container under the SMA.

All you have to do is look inside the washer and find the pump. Now you can diagnose the element and, if necessary, replace it. If you have doubts that you can cope with the repair, it is better to seek help from the service center specialists.

First of all, the part is checked with a multimeter. The tester probes are placed against the pump contacts, and then the readings on the device screen are evaluated.Normally, the output resistance should be 150-250 Ohms.

Looking for a problem during disassembly

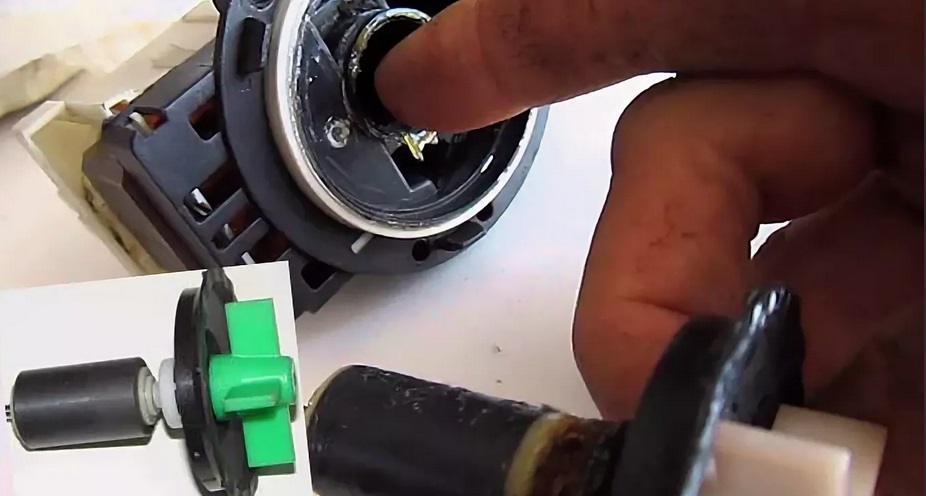

The key step is disassembling the pump. Only during this procedure will it be possible to understand whether the impeller rotates and how securely it is held by the clamps. An internal check is necessary if the movement of the blades is difficult, but there are no visible obstacles - debris or foreign objects.

Whirlpool machines can have standard pumps, which are considered collapsible, or non-separable elements. In the first case, you need to proceed as follows:

- unhook the pump from the volute by removing the fixing bolts;

- press on the part on the side where the drain valve is located, then pull the body towards you;

- drain the water that has accumulated there from the housing;

- pry up the locking latches located on both sides of the pump;

- remove the pump from the reel.

Even non-separable pumps can be halved. In this case, you need to act more carefully. The algorithm will be as follows:

- wear protective gloves;

- unhook the pump body from the volute and coil;

- take a hair dryer, run the lowest temperature blowing program;

- warm up the “shank” of the pump (this is the long tip located at the back) for several minutes;

- use a screwdriver to pick up the crosspiece and remove it from the body;

- also remove the magnet, due to which the structure is considered non-removable;

- clean the magnet and seat from debris, plaque and dirt;

- remove the magnet from the pump shaft.

Sometimes, to fix a pump, it is enough to clean its “insides”. Therefore, you can try to remove the debris, lubricate the bearings on the magnet, and reassemble the part. If such actions do not produce results, you will need to change the pump.

Before installing a new pump, be sure to clean all elements of the drain system. We are talking about the snail, the supplied pipes, and the seat. The part is secured with the bolts removed during dismantling.

Once you've finished installing the new pump, be sure to test the washing machine. Run an idle cycle, with no laundry in the drum. A short “Rinse + Drain” mode will be enough. If the water flows freely into the sewer, the repair can be considered successfully completed.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment