Disassembling a Siemens washing machine

Often, the breakdown of an old Siemens washing machine forces the consumer to buy new equipment. But in some cases, the problem can be fixed by yourself. To do this, you need to know how to properly disassemble a Siemens washing machine and what tools will be useful during the repair process. The disassembly method depends on the type of equipment loading, as well as on the design features of a particular model.

Often, the breakdown of an old Siemens washing machine forces the consumer to buy new equipment. But in some cases, the problem can be fixed by yourself. To do this, you need to know how to properly disassemble a Siemens washing machine and what tools will be useful during the repair process. The disassembly method depends on the type of equipment loading, as well as on the design features of a particular model.

Do you need a lot of tools?

At first glance, the procedure does not seem particularly complicated. It does not require the use of a large number of tools. To get started, just one screwdriver is enough. To completely disassemble the equipment, you will need a few more things:

- screwdriver;

- slotted and Phillips screwdrivers;

- a small hammer, preferably a mallet;

- pliers;

- hexagons.

Sometimes joints and fasteners may become stuck. To unscrew a stubborn screw, it must be treated with a universal anti-corrosion penetrating lubricant. W.D.-40, often used by motorists. And to drain dirty water from a hose, you will need a large container. A smartphone with a camera is useful for disassembling it yourself. During repairs, take step-by-step photographs, this will greatly help in the reassembly process. This way you can avoid mixing anything up and start the machine without any problems after completing the repair work.

Let's get to the "main" node

At the very beginning, disconnect the washing machine from the electrical network. Turn off the water supply. Unhook the supply hose and drain hose, lowering the latter into a previously prepared basin. This will ensure safe work and not flood everything around with water.

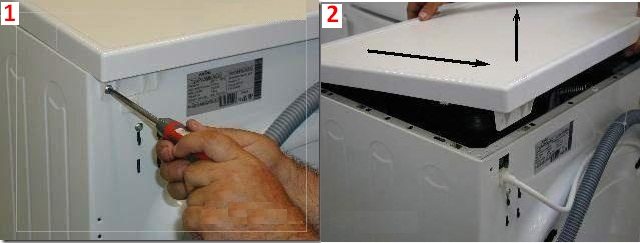

We remove the hatch door by unscrewing two screws and removing it along with the metal hinge. Remove the upper part of the body. Usually the cover is fixed with various screws, which are unscrewed with a Phillips screwdriver. The fastening elements are located on the back side under the top of the panel on the eyes. Unscrew them and press firmly on the front end of the cover, then lift it up.

How to remove the detergent dispenser yourself? Feel for a separate plastic button in the center of the drawer. Press it and pull the tray towards you.

Next step: dismantling the control panel. The latter is secured to the washer body with two screws. The first is located under the tray for washing powder and other products. The second one is in the opposite direction. When unscrewing the panel, be careful, as it is very fragile.

Life hack: after removing, hang the panel on a hook or place it separately on a table/window sill so as not to accidentally damage it.

Step number four is disassembling the service panel. To do this, simultaneously press the two locking clips and then the latch located in the middle. Remove the panel.

To remove the front wall, remove the metal clamp holding the washer door seal. You can easily pick it up with a screwdriver, the main thing is to act carefully so as not to pierce the cuff. A rubber cuff seal is installed inside the loading hatch. The clamp itself is secured with a small spring; Just push it a little and the clamp will be removed. Now place the cuff inside the drum. Do not try to pull out or pull out the seal - it is held in place by an additional internal lock.

Now it's time to dismantle the front panel, but there may be some difficulties.You will need to complete the following steps (be especially careful with the panel, there are chips inside):

- remove the front panel;

- unclip the latches responsible for securing the protective cover;

- Lift the panel and remove the hooks holding it in place.

To remove the back cover, unscrew the screws with a screwdriver. They are usually located along the entire perimeter of the rear wall of the washing machine. According to the manufacturer's idea, this allows you to securely fix the housing element, which, in fact, protects the drive mechanism.

Remove the drum from the tank body

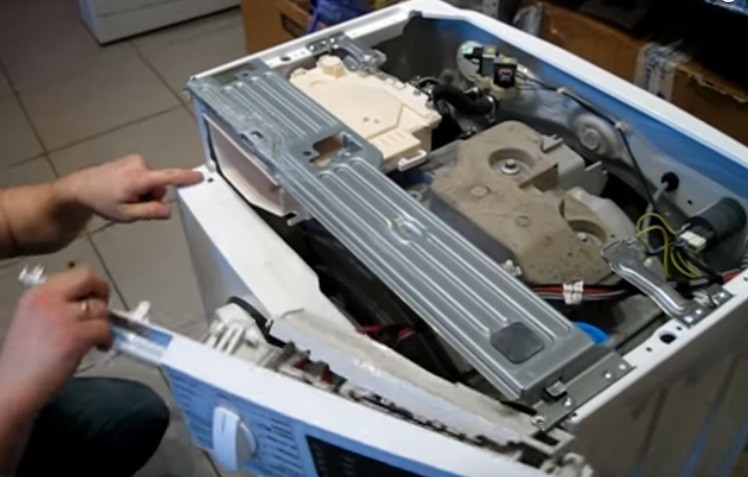

The washing machine tank weighs up to 10 kilograms. But removing it with your own hands alone is a dubious undertaking, so we recommend calling a friend/neighbor for help. Together we remove the tank from the springs and pull it out. We unscrew the front counterweight (this part most often looks like a massive half ring) and remove it. We turn the tank with the open side down, providing ourselves with access to the pulley.

To prevent the pulley with the drum shaft from spinning, block it with a block. Unscrew the bolt in the middle of the pulley with a hex screwdriver. If the bolt does not budge, lubricate it with WD-40. After waiting a little, try again. During manipulation, be careful not to tear off the hexagon.

The bolt is unscrewed counterclockwise. The process is difficult, since the fastening element is filled with a special compound, which gives the connection special strength so that it does not fall apart from vibration. Some craftsmen recommend heating the bolt with a gas torch to make work easier. We still recommend using WD-40 lubricant, since using a torch can cause damage to other parts of the machine. Grab the pulley with both hands. Pull the piece up, rocking it from side to side.After removing the spare part, disassemble the tank body into two halves.

Important! The tank of Siemens washing machines is collapsible; it consists of two parts, fastened together with long screws.

Now take an 8mm socket wrench and unscrew all the screws that hold the tank together. After this, the latter splits into two halves. But we still have the back part, connected to the drum using bearings mounted on the shaft.

They will have to be removed with the tank itself. We select any old bolt suitable for the shaft thread (where we unscrewed the screw holding the pulley) and screw it in. Then we substitute a small wooden block and lightly hit it with a hammer until the back wall of the tank comes off the bearing. So, we removed the wall, and we were left with part of the drum with the cross and shaft installed on it. The shaft is fitted with an oil seal and a bearing. Let's get to the hardest step.

- We drive the puller's grips under the bearing.

- By slowly tightening the thread of the puller, we create a certain tension.

- Lubricate the bearing thoroughly with WD-40.

- We wait about half an hour.

- After this, we continue to unscrew the thread and, as a result, remove the bearing, and then the oil seal.

Now you know all the intricacies of disassembling a Siemens washing machine with your own hands. By removing parts one by one, you can easily get to the components and elements that need repair. When reassembling, carefully follow the instructions without skipping any steps.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment