Disassembling the washing machine drum

Failure of washing machine bearings is perhaps the most unpleasant malfunction that can happen to a home helper. The problem is not so much in eliminating the malfunction itself, but in getting to the parts that interest us, because for this we will have to literally disassemble most of the machine. The main thing is to disassemble the tank, which is assembled with the drum, and this is not so easy to do. In our article we will touch on the issues of disassembling different types of front-loading washing machine drums.

Failure of washing machine bearings is perhaps the most unpleasant malfunction that can happen to a home helper. The problem is not so much in eliminating the malfunction itself, but in getting to the parts that interest us, because for this we will have to literally disassemble most of the machine. The main thing is to disassemble the tank, which is assembled with the drum, and this is not so easy to do. In our article we will touch on the issues of disassembling different types of front-loading washing machine drums.

Basic Rules

After watching a lot of thematic videos and pictures on the Internet, the user acquires unhealthy self-confidence and begins to believe that he can completely disassemble the washing machine along with the drum, and then put it back together in a matter of hours. In fact, disassembling the tank and drum is fraught with many pitfalls. If you don’t know them, then you can ruin an important detail of the “home assistant” so that even the master will not help you later.

After watching a lot of thematic videos and pictures on the Internet, the user acquires unhealthy self-confidence and begins to believe that he can completely disassemble the washing machine along with the drum, and then put it back together in a matter of hours. In fact, disassembling the tank and drum is fraught with many pitfalls. If you don’t know them, then you can ruin an important detail of the “home assistant” so that even the master will not help you later.

When wondering how to disassemble the washing machine drum, you must first get to it, and to do this you will have to remove almost all the parts from the body, since they will interfere with the removal of the tank and drum. How to do this is illustrated in detail in the article. How to disassemble a Zanussi washing machine. Although this publication is about a specific brand of washing machine, it is very indicative and allows us to draw analogies with any other brand of washing machine.

So, what are the rules for disassembling the drum and tank? What do you need to remember when doing this work? Let's briefly summarize these rules.

- Remove the tub and drum from the washing machine body very carefully. The tank in most modern washing machines is plastic and does not tolerate any mechanical stress. When removing the tank, use the help of a friend.

- Before sawing a non-separable tank, drill many holes for fasteners with a thin drill across the seam. This way you will prevent displacement. The more bolts there are in a circle, the better it will be possible to tighten the halves of the tank, and of course, do not skimp on the sealant.

- You need to cut a non-separable tank exactly along the welded plastic seam, which is clearly visible from the side. In most places, a bevel of even a couple of millimeters is unacceptable.

- When unscrewing the screw holding the drum pulley, be extremely careful and careful. You can’t unscrew it without effort, but if you put in extra effort, you will tear off the edges of the head, which will add to your problems.

- To remove the back of the washing machine tub from the shaft, you will have to give the shaft a couple of light blows - do not overdo it.

A stuck bearing can be removed using a washing machine puller. You may need to heat it slightly with a blowtorch before removing it.

What will you need?

To disassemble the tank with the drum of a washing machine, you will need, in general, a simple tool. Most of the required tools are probably still in your pantry, but for some you will have to go to the garage, or maybe to a neighbor. What will you need?

- Phillips, hex, flat screwdriver (in some washing machine models, a flat and Phillips screwdriver is sufficient).

- A small adjustable wrench.

- Heads and open-end wrenches (set).

- Automotive puller designed for removing bearings.

- Blowtorch.

- A hacksaw for metal and a lot of blades for it.

- Drill and thin drill bits.

- Wooden block and hairpin.

- A heavy copper hammer.

- Wire cutters and round nose pliers.

Among other things, it's a good idea to have WD-40 lubricant on hand. It will help deal with stuck fasteners and simplify disassembly. You can use a gas torch instead of a blowtorch, but it will produce a lower temperature and the bearing may not get hot enough to come off.

Do not use a blowtorch indoors. It is preferable to disassemble the washing machine tank somewhere in a garage or shed, or better yet, outside under a canopy.

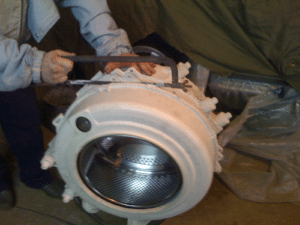

Removable tank

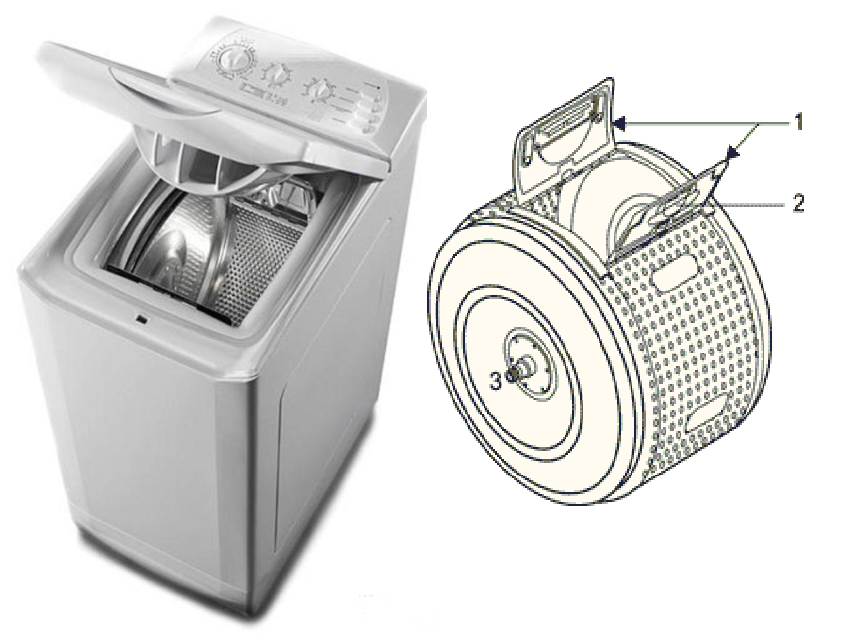

Approximately half of all modern automatic washing machines have collapsible tanks. This is very convenient and makes life much easier for washing machine repair technicians, speeding up disassembly. In a washing machine with a collapsible tank, the two halves of this tank are bolted together. In addition, the joint is either coated with sealant or sealed with an elastic band so that water does not seep through. To disassemble a dismantled tank with a washing machine drum you need:

- use a wooden block to jam the drum pulley, the tank itself with the drum must be positioned with the hatch down;

- take a head of a suitable size with a ratchet and try to unscrew the bolt holding the pulley on the shaft;

- we remove the pulley, and then, taking a suitable key, we begin to unscrew the bolts that connect the halves of the tank;

- Having unscrewed the tank halves, we apply a couple of light blows to the shaft and pull off the back of the tank;

- Using a blowtorch or gas torch, heat the bearings and pull them off using a puller.

There are often cases when bearings come off the shaft without problems, so a puller is not required.

Non-removable tank

With a non-separable tank, we do much the same as with a collapsible one. The only difference is that it needs to be sawed. Anyone who has ever done this work knows how difficult, dreary and thankless it is. The main problem is that not a single handy tool in its pure form is suitable for this work.

- A hacksaw often gets stuck and blades break.

- A thin wood hacksaw cuts too thickly, so that it is then difficult to ensure a tight connection between the halves of the tank.

- An angle grinder is not suitable at all, since the disc can slip off at any time and damage the tank; in addition, when working with an angle grinder it is difficult to regulate the depth of cut, and this risks damaging the steel drum.

- A jigsaw is generally suitable, but in some areas you have to use a hacksaw again.

When cutting a tank, experts advise using a regular hacksaw for metal along with a hacksaw blade, which should be wrapped with electrical tape on one edge to make it easier to hold. You will use such an improvised saw in those areas of the weld where cutting with a regular hacksaw for metal would be inconvenient. If after 3-4 hours you manage to saw the tank properly, consider half the job done, and if the old bearings come off without problems, consider the disassembly a success.

In conclusion, we note that in order to disassemble the washer drum, you must first spend a lot of time to remove it, and only then proceed directly to disassembly. If the tank on your washing machine model is not removable, you will spend many times more time disassembling it. Be careful and careful!

Interesting:

1 reader comment

Thank you, Vladimir, for the video. Everything is detailed and intelligible.