Disassembling the drum of a Bosch washing machine

If there are problems with bearings and seals, almost complete disassembly of the Bosch washing machine is necessary. However, the initial easy removal of elements on the approach to the tank is difficult: the assembly is heavy, there are many fasteners, and you have to act “in the dark.” Despite the difficulties, anyone can disassemble a washing machine drum at home. You just need to prepare the tools and act according to a certain scheme. Let's tell you in more detail what, how and why.

If there are problems with bearings and seals, almost complete disassembly of the Bosch washing machine is necessary. However, the initial easy removal of elements on the approach to the tank is difficult: the assembly is heavy, there are many fasteners, and you have to act “in the dark.” Despite the difficulties, anyone can disassemble a washing machine drum at home. You just need to prepare the tools and act according to a certain scheme. Let's tell you in more detail what, how and why.

Let's take everything we need

The beauty of the Bosch machine is that it is repairable. Moreover, the manufacturer has made disassembling the case as easy as possible, which allows you to cope with the task quickly. All components of the system are connected with self-tapping screws, bolts or clamps, so the work requires a minimum of tools. It is enough to prepare screwdrivers and pliers, but it is better to simplify the task and additionally find:

- round nose pliers;

- set of wrenches;

- chisel;

- hammer;

- awl;

- stationery knife;

- universal key.

Before disassembling the Bosch washing machine, it is strongly recommended to study the factory instructions!

Having prepared the tools, we proceed to the “paper” work - studying the factory instructions. As a rule, all Bosch models have an identical design, but it is better to eliminate the possibility of error. We pay special attention to the type of engine installed. The inverter motor is connected to the drum directly, while the collector motor involves transmission through a belt and pulley. We also look at the location of the heating element, pump and pipes.

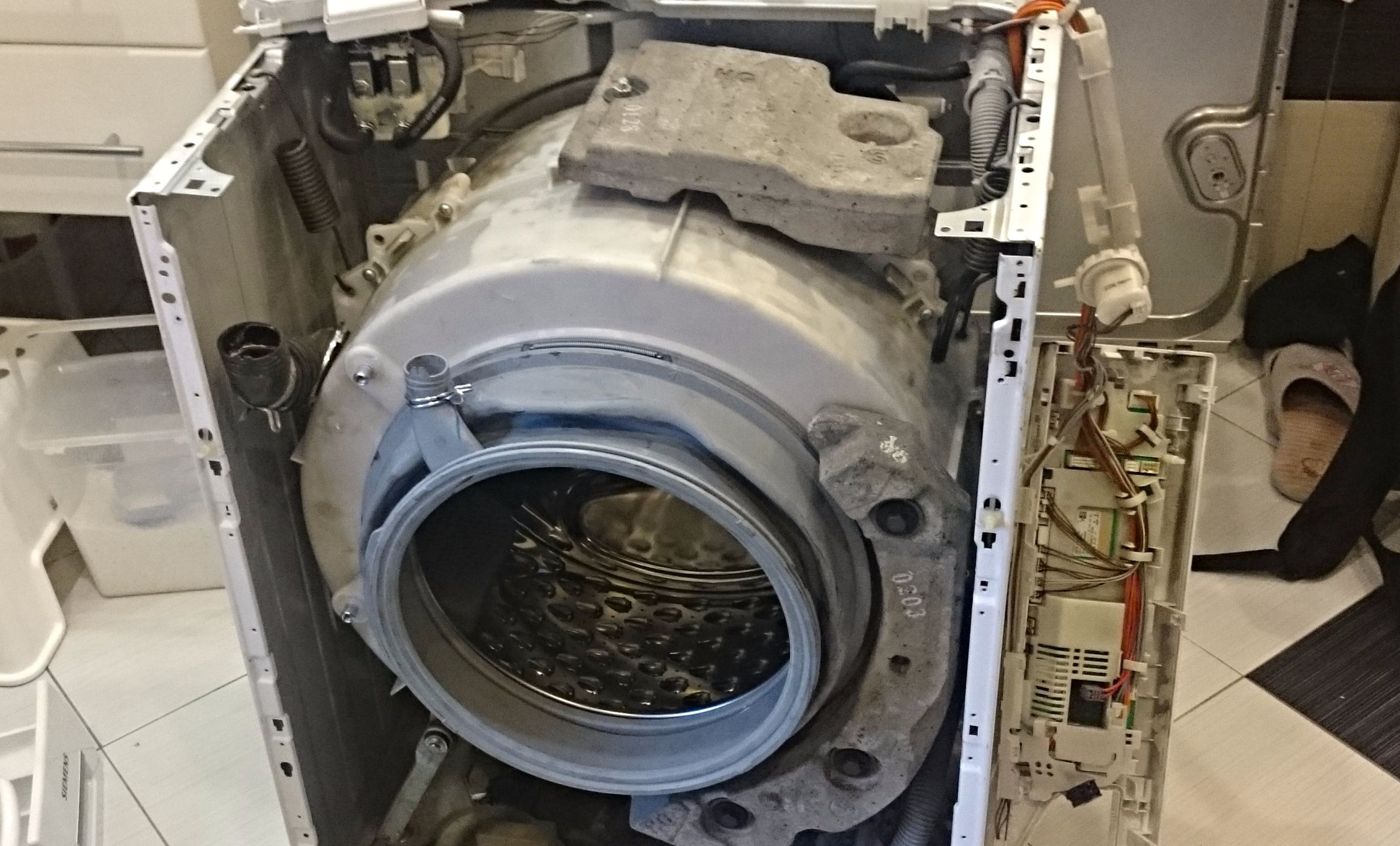

Getting to the tank-drum assembly

To begin disassembling the tank, you must first “reach” it.To do this, you will have to sequentially disconnect almost all the elements of the washing machine from the body. It is not difficult to do this yourself if you do not deviate from the instructions.

- Disconnect the machine from communications.

- Empty the drum (first activate the “Drain” program, then unscrew the garbage filter).

- Make sure there are no items in the drum.

- We turn the washing machine with the back panel towards you.

- Remove the back and top panels.

- Disconnect the counterweights by unscrewing the holding bolts.

- We unhook the dashboard and powder dispenser.

- We remove the pressure switch from the housing.

- We remove the hatch cuff and the door.

Before any manipulations, Bosch must be de-energized and disconnected from the water supply - otherwise there is a high risk of electric shock!

Next in line is the tank, which needs to be freed from all connected wires, elements and connections. First, disconnect the hoses from the plastic, then remove the engine, dampers and springs. All that remains is to grab the drum, lift it and remove it from the body. This is not easy to do, so it is better to call someone for help.

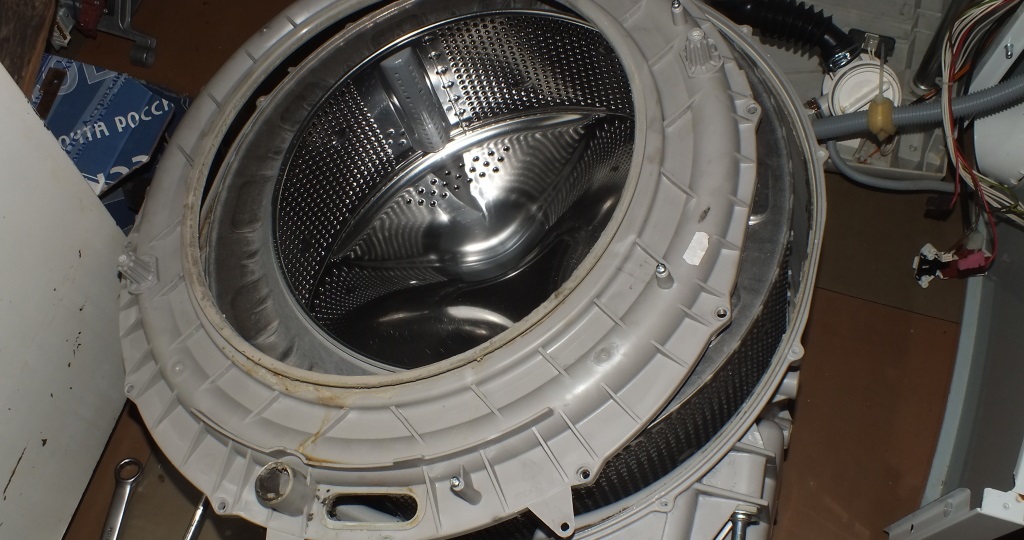

Divide the tank into two halves

Place the removed tank on a dry, flat surface and begin disassembly. To make it easier and simpler, it is better to clean the surface of the tank from soap deposits. Next, put on gloves and follow the following instructions:

- break the blade of a stationery knife into pieces 1-3 cm long (any thin plates will do);

- Use a thin flat screwdriver to pry up the latch on the seam, lift it up and insert a piece of blade under the plastic;

- repeat the procedure until there is a blade under each latch;

When working with blades, be sure to wear gloves!

- unscrew all existing screws;

- insert a screwdriver into the middle of the seam along the entire perimeter and slowly try to halve the tank;

- remove one half of the tank;

- turn the tank upside down;

- We cling to the shaft with a universal wrench and unscrew the axle;

If the shaft is “stuck”, then the joints are treated with WD-40 cleaner.

- disconnect the second half of the tank from the drum.

Service center repairmen often act more treacherously; they do not place plates under the latches, but simply break them. This speeds up disassembly of the tank, but weakens its structure. The fact is that without plastic clamps the tank is “held” only by self-tapping screws. This is acceptable, but still unreliable.

After freeing the drum, you can begin repairing the unit. As a rule, the final stage of such disassembly of a Bosch machine is planned to replace the bearings. In this case, first the oil seal is removed and the cross is unscrewed, and then both “rings” are knocked out with a chisel and hammer. Next, the seat is thoroughly cleaned with WD-40. Then new elements are installed, and the joint is treated with silicone sealant. The tank is assembled in the same way, only in reverse order.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment