Replacing the cuff on a Miele washing machine

Is it possible to change the cuff on a Miele washing machine at home? Definitely yes. This repair is not considered difficult. Some experts recommend replacing the seal without dismantling the front wall of the case, others recommend removing the front panel, “tidy” and top cover. Let's look at the progress of the upcoming work step by step.

Is it possible to change the cuff on a Miele washing machine at home? Definitely yes. This repair is not considered difficult. Some experts recommend replacing the seal without dismantling the front wall of the case, others recommend removing the front panel, “tidy” and top cover. Let's look at the progress of the upcoming work step by step.

Preparing the machine for repair

You need to prepare for any repair. First of all, look through the instructions for the Miele washing machine. The structure of the washing machine is described there - this will not interfere with a novice master.

The next stage is the purchase of new components. To ensure the cuff fits properly, check the model name of your SMA Miele. Then the salesperson in the store will be able to select a similar seal. You can order an elastic band on the Internet, but there is a risk of making a mistake with the sizes.

You can first start dismantling it, take out the old seal and go to the store with it. Then it will be easier for the seller to choose an analogue. There are markings on the cuff, so it will be impossible to make a mistake with the size.

It is better to immediately prepare the tools that may be required for the job. The list is small. To change the cuff, just have on hand:

- Phillips and slotted screwdrivers;

- flashlight;

- a screwdriver with a set of bits (if you are too lazy to unscrew the screws with a screwdriver).

Now you should take care of the machine itself. First, turn off the power to the equipment by unplugging the power cord from the outlet. Next, close the shut-off valve on the water pipe and unhook the drain and inlet hoses from the body. Then you need to move the washing machine to the place where the repair will take place.

During repairs, be sure to follow basic safety precautions.

This is where the preparation ends. Now you can start repairing. It is more correct to change the hatch cuff by removing the front wall of the housing, the instrument panel and the top cover. Therefore, we begin to partially disassemble the washing machine.

Release the rubber band for normal dismantling

To easily remove the rubber seal, you will need to partially disassemble the washer body. First of all, the top panel is removed. For this:

- go around the back of the car;

- Unscrew the screws securing the top panel;

- pull the “lid” towards you and lift it up;

- move the removed panel aside.

Next, you need to remove the powder receptacle from the machine. Pull the tray all the way and press the plastic tab in the center of the cuvette. After removing the detergent dispenser, you can begin dismantling the dashboard.

The control panel is held in place by several screws. Some of the screws were hidden by the top cover, two by the powder receptacle. Now all the bolts can be unscrewed with a regular Phillips screwdriver.

Next, you need to remove the dashboard of the automatic machine. It is now held in place only by a few latches. You can press out the fasteners with a screwdriver. Press the locking elements one by one and carefully unhook the “tidy” from the body.

Behind the control panel there will be a bundle of wires connecting it to the electronic module. There is no need to unhook them. Just carefully place the appliance on top, on the corner of the washing machine.

Then you need to work with the lower part of the SMA body. Take a slotted screwdriver and hook the technical hatch door covering the garbage filter. The element is located on the decorative panel.

After opening the hatch door, carefully move the emergency drain pipe aside - the hose may interfere with further dismantling. Use a Phillips screwdriver to remove the bolt securing the false panel. The self-tapping screw is located either to the right or to the left of the drain filter - its location depends on the Miele SMA model.

Next, all that remains is to unfasten the decorative panel. It is held in place by several latches. Carefully grasp the element and pull it off the latches, first on the right, then on the left.

Then you need to remove the front sealing collar. It is necessary to remove it right now, as it will interfere with the dismantling of the front wall of the case. How to proceed:

- open the drum door wide;

- find the spring on the cuff clamp;

- pry up the spring with a slotted screwdriver;

- Carefully pulling the spring towards you, pull off the clamp.

It is even easier to remove the front cuff clamp using a dull table knife.

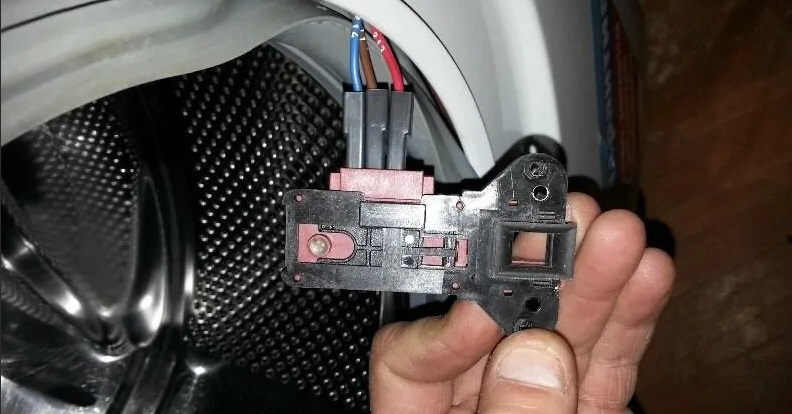

After removing the clamp, tuck the sealing rubber into the drum so that its edges do not cling to the front wall of the housing. Otherwise, it will interfere with the removal of the front panel of the MCA. Then work with the lock-lock - unscrew the two screws holding the locking device. The bolts are located to the right of the hatch and can be removed with a regular Phillips screwdriver.

Now only a few screws prevent the removal of the front wall of the Miele automatic machine. Unscrew the screws and carefully push the UBL out of the panel so that the lock falls inside. Then you can remove the front part of the SMA housing.

There is no need to disconnect the hatch door - it is better to leave it assembled with the front wall. After this, all that remains is to unhook the hose connected to the cuff fitting. This completes the main part of the disassembly.

Remove the old cuff and install a new one

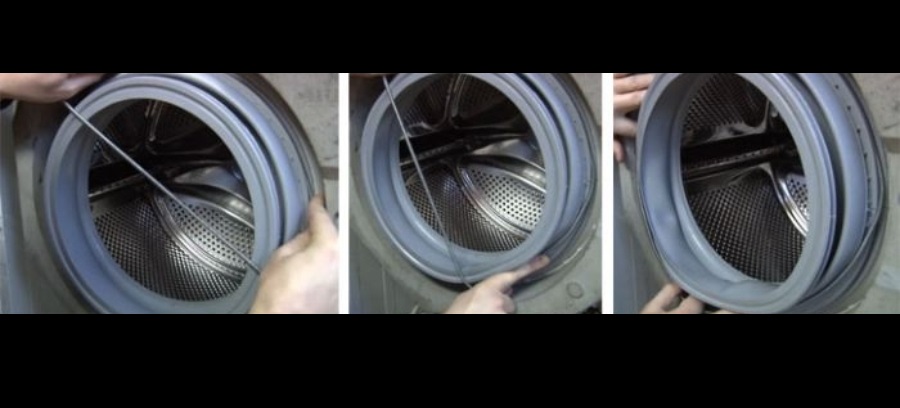

Now is the time to remove the old rubber seal and install a new one. The drum cuff is fixed with an external and internal clamp. The front ring has already been removed - all that remains is to dismantle the previously hidden element.

Dealing with the internal clamp is quite simple. Removing the front wall provided access to the ring. You also need to use a screwdriver to pick up the spring and pull out the rim.

The next stage is the actual dismantling of the cuff. Grasp the seal with both hands and forcefully pull it out of its seat. Don't be afraid to damage the rubber band; it will still be thrown away.

Be prepared to find a lot of dirt under the cuff. Clean the seat from any accumulated debris. Next, you need to remove the bushing from the old seal and place it on the new part.

Then the new cuff is turned over with the fitting facing up. It is important to install the seal correctly. The arrow on the gasket should coincide with the mark on the SMA body, and the technological recesses should be at the bottom.

It is very important to position the cuff correctly - the drain holes should be at the bottom.

Having figured out the location of the seal, pull it onto the seat. Next, the cuff is fixed with an external clamp. You can buy a new rim or install an old one.

Fixing the cuff with clamps is the most difficult part of the repair. “Spare hands” may be required here, so it is better to call an assistant. Stretch the spring a little and put the rim in place. To make installation easier, use two slotted screwdrivers.

You need to be careful with the new cuff. Sometimes, when tightening the clamps, the seal is pierced with screwdrivers. In this case, you will have to run to the store for a new gasket, so be careful.

After installing the internal clamp, we can talk about reaching the “finish line”. Further steps are performed in reverse order:

- connect the hose to the cuff fitting;

- replace the front wall;

- straighten the edges of the cuff, “grasping” them the front panel of the MCA body;

- secure the UBL;

- Replace the outer cuff clamp;

- assemble the body of the machine (by installing a decorative panel, a “tidy”, and a top cover);

- connect the washing machine to the communications.

Replacing a cuff is not as difficult as it may seem. Even a beginner can handle this kind of work; moreover, no special tools are required. The main thing is not to deviate from the instructions and follow safety precautions.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment