Resetting your Beko washing machine

Generally, for users, resetting the washing machine is the key to solving many problems. Forgot to put something in the drum? Rebooted the washer and continued. Confused about the program? The same. Did you remember that you forgot your pass in your jeans pocket? Even here, the first thing that comes to mind is to turn off the washing machine, take out the item, then turn it on and resume washing. Let's consider when it may be necessary to restart the Beko washing machine, whether it is even possible to do this and how.

Generally, for users, resetting the washing machine is the key to solving many problems. Forgot to put something in the drum? Rebooted the washer and continued. Confused about the program? The same. Did you remember that you forgot your pass in your jeans pocket? Even here, the first thing that comes to mind is to turn off the washing machine, take out the item, then turn it on and resume washing. Let's consider when it may be necessary to restart the Beko washing machine, whether it is even possible to do this and how.

Stopping the program and restarting

The washing machine must be stopped safely before resetting. The fact is that an emergency shutdown is not at all harmless, and can lead to serious failures in the control module and subsequent expensive repairs. A safe program reset is performed as follows:

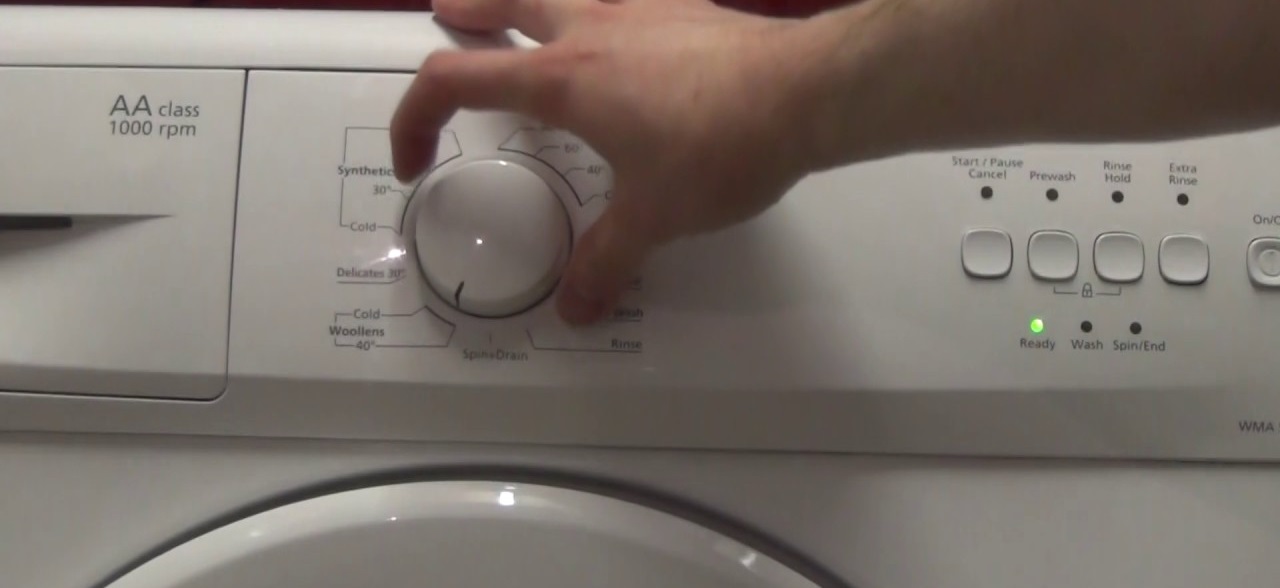

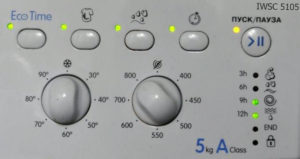

- press the “Start” button and hold for 4 seconds;

- all the lights on the front panel should simultaneously glow green and then go out;

- the program will stop working;

- If the washing machine has a program selector, you need to set it to the neutral position.

A successful stop is indicated by the machine quieting down and the lights on the control panel systematically blinking. If any of this does not happen, something did not go according to plan, and you need to restart the machine. This is done like this:

- set the program selector to the first position;

- press the “Start/Pause” button and hold for about 5 seconds;

- remove the power plug from the socket;

- reinsert the plug into the socket after a few seconds;

- restart the desired program.

Important! If even after all these manipulations the machine does not respond to starting the wash, you must immediately disconnect it from the power supply!

Remove the plug from the socket without sudden movements, carefully so as not to damage the electronic contents of the unit.

Restart required due to error code

We are talking about a Beko washing machine, so below is a list of error codes that are relevant for washing machines from this particular manufacturer. So, if you see the following sets of symbols on the display, the washer may need to be reset and repaired.

- H1. The temperature sensor has failed. This is often due to an open contact between the sensor and the thermostat. Set the multimeter to measure resistance and “punch” the thermistor. At room temperature the reference value is 4700 ohms. If a problem is detected, the sensor must be replaced.

- H2. The heating element has failed. It is necessary to carefully examine the element itself, and especially its contacts. If the contacts are normal, it will be enough to replace the electric heater.

- H3. This code indicates the fact that the water in the drum is overheated due to the fact that the heating element is constantly turned on. However, the problem may lie in the same temperature sensor, the resistance of which needs to be checked with a multimeter. If everything is fine with the thermistor, the failure may lie in the control board.

- H4. The filler valve triac is closed. First of all, you need to check the wiring of the element. If everything is in order with the contacts, then the problem is in the CM control board. You will have to call a technician either to repair or replace the element with a new one.

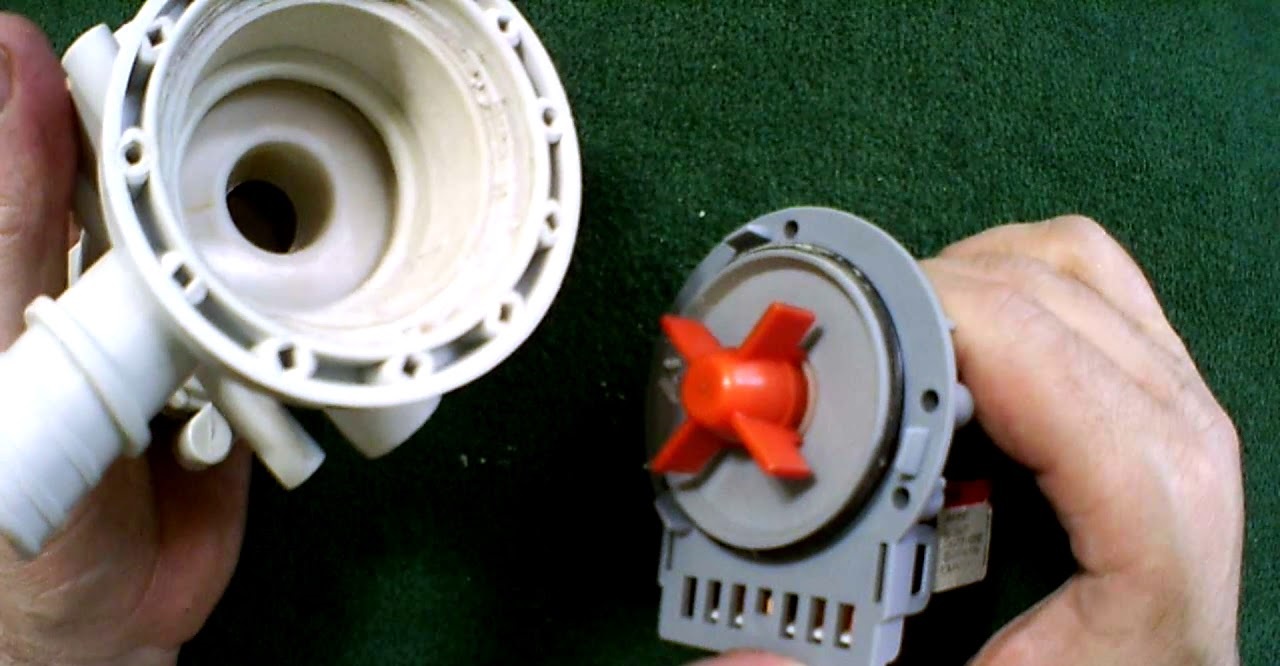

- H5. This code indicates that something is wrong with the pump. Typically, the suction power is very low.Regular cleaning can solve the problem: clean the drain filter, remove debris accumulated in the hose, align the pipes so that there are no kinks or kinks. If none of this helps, you will have to replace the pump.

- H6. Indicates that a short circuit has occurred in the motor triac. However, practice shows that the code can also indicate other problems with the “engine” triac: its failure, broken contacts, and generally a failure in the control board.

- H7. Damage to the water level sensor. Malfunctions with the pressure switch can be associated with the following factors: a break in the contacts between the sensor and the central control module of the unit, failure of the element itself, as well as a failure in the corresponding section of the control board.

Attention! Sometimes even a breakdown of the locking device can be accompanied by error code H7!

- H11. Rupture in the engine circuit. It is necessary to check all engine contacts, tachogenerator wiring, inspect the wires from the electronic controller to the “engine” for integrity and safety. If everything is in order with this, you should inspect the engine itself and the tachogenerator.

Sometimes, when error codes are displayed, the washing machine really needs repairs, even simple and independent ones, and sometimes a simple reboot can solve the problem of failure. The main thing is to follow the safety instructions.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment