Leran washing machine error codes

Modern Leran automatic washing machines are equipped with a self-diagnosis system. The smart program detects problems and notifies the user about them, displaying the corresponding fault code on the display. Let's figure out what errors washing machines of this brand can produce, where to look for the explanation, and what to do to fix the breakdowns.

Modern Leran automatic washing machines are equipped with a self-diagnosis system. The smart program detects problems and notifies the user about them, displaying the corresponding fault code on the display. Let's figure out what errors washing machines of this brand can produce, where to look for the explanation, and what to do to fix the breakdowns.

Let's decipher the codes of the self-diagnosis system

You can see what the error codes for Leran washing machines mean in the instructions for the equipment. Therefore, if some incomprehensible symbol appears on the display, immediately open the user manual. If the booklet is lost, look for the transcript on the Internet.

The self-diagnosis system of Leran washing machines helps to quickly identify and fix the problem.

Often, users, understanding what kind of failure the washing machine is indicating, fix the problem with their own hands. The machine itself significantly speeds up the diagnostic process. We'll tell you what errors SMA Leran can inform you about.

- F01 An error is displayed on the display when water is poured into the tank very slowly or does not flow there at all.

- F03 The code indicates that the washing machine cannot drain water into the sewer.

- F04, F05, F06, F07, F23 If any of the listed errors occurs, the machine “freezes”, stopping the washing. The reason is damage to the control module elements.

- F13 The system is leaky, the hatch locking device does not work. If such an error occurs, the Leran CMA will not start washing.

- F14 The washing machine door does not open. This error indicates problems with the hatch locking device.

- F24 The code indicates that an overflow has been detected. There is too much water in the drum.

- UNB. The error informs you that the laundry in the drum is unbalanced.This code is very easy to eliminate; just distribute the items evenly inside the machine and start the cycle again.

On different washing machines, the breakdown symbols may differ. On some models Leran instead of the letter "F"the corresponding number is preceded by "Err». To avoid confusion, it is recommended to study the instructions specifically for your washing machine.

Main problems with Leran machines

Having found out what kind of breakdown the machine is signaling, you can begin to troubleshoot the problem. In most cases, you can fix the “home assistant” yourself. If we are talking about complex repairs, for example, replacing semiconductors or soldering tracks on an electronic module, then it is better to contact specialists.

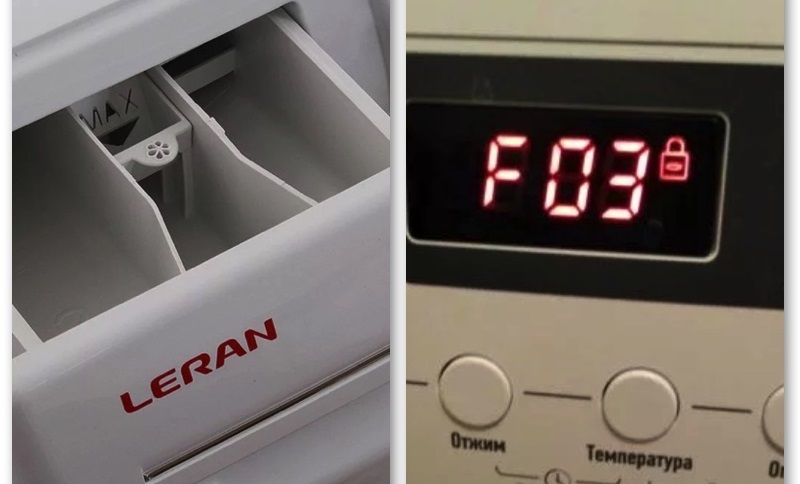

More often than others, error F03 appears on the display of Leran washing machines. This code informs that the machine cannot drain water into the sewer. The reason for this failure may be:

- internal blockage in the drainage system;

- external blockage (when a siphon or sewer pipe becomes clogged);

- incorrect connection or kinking of the drain hose;

- pump failure;

- damage to the pump wiring.

What to do when you see error F03 on the SMA display? First, you need to drain the water from the tank manually. To do this, use the emergency drain pipe or the main drain hose. You can also empty the machine by unscrewing the garbage filter. For this:

- disconnect the washing machine from the network and water supply;

- prepare a spacious container for collecting water with low sides;

- find the garbage filter (it is located behind the technical hatch door);

- cover the floor near the washing machine with dry rags;

- place a container under the device to collect water;

- Unscrew the filter half a turn, wait until some of the water pours into the basin;

- take out the “trash can” completely.

If the drain filter is unscrewed and water does not leave the machine, it means that the pipe coming from the tank is clogged.

Next, you need to clean the garbage filter and the drain hole itself. If there is scale on the coil, remove the deposit with a brush. The “trash can” can only be washed in warm water; boiling water can cause the plastic to become deformed.

Check if the common building riser is clogged. To do this, look at how the water leaves the washbasin or bathtub. If draining is also difficult, call a plumber.

Feel the CMA drain hose for blockages. If you find a plug, disconnect the pipe and rinse it under running warm water. After this, the sewage will begin to flow freely into the sewer, and the machine will no longer show an error.

If error F03 appears after several “noisy” attempts by the washing machine to drain water, then the problem is in the pump. Check the pump with a multimeter. A burnt-out part cannot be repaired; you will have to buy and install a new element.

Error F01, informing that water is not poured into the machine, may indicate:

- water tap turned off;

- insufficient pressure in pipes;

- blockage in the filling system (debris can collect in the mesh filter, valve, pipes);

- breakdown of the water level sensor;

- control module damage.

First of all, look to see if the shut-off valve responsible for supplying water to the machine is closed. Next, open the faucet in the bathroom or kitchen to make sure there is sufficient pressure in the pipes. Then check the inlet hose for blockages and kinks.

Water may not flow into the washer due to a faulty inlet valve. It is located under the cover of the SMA housing, near the wall. There are pipes connected to it, through which water passes into the powder receptacle.

The reason is not always a breakdown. Sometimes the mesh filter, which is located between the inlet hose and the solenoid valve, becomes clogged. Therefore, check the filter element first. For this:

- de-energize the SMA;

- turn off the tap responsible for the water supply;

- unscrew the inlet hose from the machine body and drain the remaining liquid from it;

- Pull out the mesh using pliers and rinse the filter.

Next, the intake valve is checked. Remove the top cover of the washer and inspect the part for damage. If everything is visually in order, remove the element by disconnecting all hoses and wiring from it.

To check, connect an inlet hose to the inlet valve and open the shut-off valve on the pipe. If the sensor is working properly, it will not leak water. Otherwise, the element will need to be replaced.

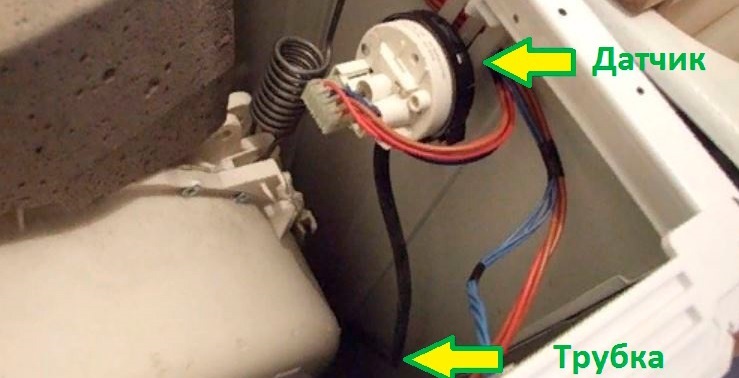

Error F01 can be generated by a damaged pressure switch. A faulty level sensor sends a signal to the control module that the tank is empty (even when it is not). The “brain” displays the corresponding code.

To check the pressure switch, it is necessary to prepare a tube with a diameter equal to the level sensor fitting. Next, open the clamp and remove the pressure hose. Place the tube in this place and blow strongly into it. If everything is fine, you will hear one or three clicks - this is how the contacts will work.

If the Leran CMA display shows errors F04, F05, F06, F07, F23, call a technician - the problem lies in the electronic control unit.

It is not worthwhile to diagnose and repair the control module yourself, without sufficient knowledge and experience. You can damage the board even more. It is recommended to entrust such complex work to a specialist.

Error F13 on Leran washing machines indicates an open drum door. There may be several reasons:

- faulty hatch locking device;

- broken door handle;

- damaged mechanical lock;

- "loose" hinges.

It is necessary to tighten the side hinges of the door, inspect and replace the latch or the handle itself. If the problem is in the UBL, the device must also be replaced.

Code F14 indicates problems with the UBL. Only in this case, the hatch door, on the contrary, does not open. You will have to open the machine yourself and change the lock.

All components are purchased for a specific SMA Leran model. You can also come to the store with a dismantled part and ask to find an analogue.

Error F24 is also typical for Leran SMA. Overflow can be caused by:

- faulty fill valve (it does not close even when the tank is already full);

- broken pressure switch (the sensor signals that there is no water, the control module does not give the command to finish drawing water, an overflow occurs);

- a failed drain pump (water is poured into the tank, but is not pumped into the sewer).

How to check the solenoid valve, pressure switch and pump has already been said. It is better to perform diagnostics from simple to complex. The water level sensor is inspected first, then the inlet valve, then the drain pump.

There is nothing difficult in diagnosing SMA Leran. The internal intelligent system of the machines helps narrow down the range of possible faults. Most problems can be resolved on your own, at home, without the help of a professional.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment