UNB error in Haier washing machine

The longer and more intensively we use household appliances, the higher the chance of encountering one or another error on the display. The UNB error in the Haier washing machine is almost the most common, so almost every third user of the “home assistant” from this brand is familiar with a similar problem. It occurs because the equipment has detected an imbalance, which could have occurred due to the fact that the clothes inside the drum gathered into a large dense lump and began to hit the walls of the drum during the spin cycle. However, the error does not always appear because of clothing, which we will look at today.

The longer and more intensively we use household appliances, the higher the chance of encountering one or another error on the display. The UNB error in the Haier washing machine is almost the most common, so almost every third user of the “home assistant” from this brand is familiar with a similar problem. It occurs because the equipment has detected an imbalance, which could have occurred due to the fact that the clothes inside the drum gathered into a large dense lump and began to hit the walls of the drum during the spin cycle. However, the error does not always appear because of clothing, which we will look at today.

Causes of imbalance

A malfunction caused by an imbalance is often associated with laundry that has collected in a large lump during the washing process and created the illusion of severe overload. The error could also be caused by actual overload, if the user mistakenly loaded too many clothes. If this is exactly the problem, then everything is very easy to fix with your own hands - you just need to remove excess laundry if overload is to blame, or evenly lay out the clothes if they are bunched up. But what to do when the cause of the breakdown is not the laundry?

- The transport bolts were not removed. A fairly common situation is when a housewife unknowingly fails to remove the bolts that hold the drum in a stationary position during delivery. If they are not removed before the work cycle, the machine will spin the locked drum while the tank is fixed. This threatens to damage the internal elements of the equipment. Under no circumstances should you start the “home assistant” until the bolts from the rear wall of the CM have been removed.

Starting a washing machine with shipping bolts will void the manufacturer's and store's warranty, so you should never forget about them if you don't want to pay out of pocket for equipment repairs.

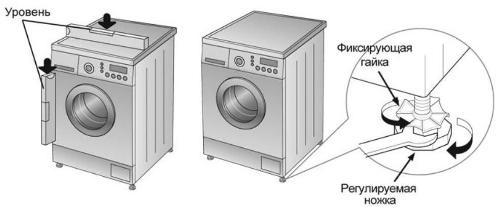

- Installation errors. Household appliances must stand on as level a surface as possible so that during operation they do not suffer from excessive vibration and imbalance. That is why before installation it is better to carefully level the floor, and also purchase a special anti-vibration rubberized mat, or special rubber attachments for the legs. It is better to place equipment on tiles or concrete, avoiding laminate, linoleum, carpets and other unstable coverings.

- Damage to shock absorbers. These units are needed precisely to reduce machine vibrations during operation. If the rubber gaskets in the dampers wear out over time and the fasteners become loose, the unit will begin to suffer from serious imbalances during spinning and washing. It’s very easy to check if the damper is working properly – open the top panel of the washing machine and carefully press on the tank. If it jumped a few centimeters and stopped, then everything is fine, but if after these manipulations you see chaotic movements from side to side, accompanied by jumps, then the unit needs to be repaired or replaced.

- Malfunction of counterweights. The shock absorption system of washing machines consists not only of dampers, but also of concrete counterweights installed in the device in order to actively dampen vibration. When these concrete blocks are damaged, they not only cannot reduce vibration and imbalance of the system, but also actively hit other components of the machine, creating an additional danger for expensive equipment.If the counterweight is covered with cracks, or its retaining element is worn out, then it must be replaced, or you can try to restore it yourself.

If the cracks on the counterweight are not too large, then you can try treating them with concentrated cement mortar.

- Bearing problems. Finally, it is worth considering a problem with the bearing assembly, which can be determined by the extremely slow rotation of the drum, accompanied by an unpleasant clanging sound. If you find this behavior of the “home assistant”, then most likely the UNB error appeared precisely because of this problem. In this case, you will have to call a service center specialist, since it is better to entrust the repair and replacement of bearings to professionals.

It is believed that if the washing machine is installed correctly and its operation is carried out strictly in accordance with the recommendations of experts, then it will serve the user approximately 5-7 years longer than the standard warranty period. This is why it is so important to prevent imbalance in the system. It is very convenient that many modern washing machines have an automatic rebalancing function that prevents errors from appearing UNB, which extends the overall life of the equipment.

Why does the machine record an imbalance?

From the outside it may seem that there is nothing wrong with the imbalance, so it is not necessary to monitor it so closely. In fact, eliminating this malfunction is very important, if only because it negatively affects the washing machine’s electric motor, its shock-absorbing system and other key internal components. The user can almost always detect an overload with the naked eye during a spin cycle - the machine will vibrate strongly, jump and make uncharacteristic sounds.To cope with this unpleasant situation, Italian and Korean equipment manufacturers have developed a special automatic balancing system.

Its principle is that special sensors are placed in the tank that monitor the accumulation of things in one area of the drum. As soon as the equipment detects the slightest overload, it will send a signal to the control board, which will stop the working cycle, start the reverse rotation of the drum and thus get rid of the imbalance. Moreover, if the “home assistant” cannot cope with the laundry in the drum, which has gotten into a lump, then she will inform the user about this so that he can independently correct the balance of the system. Thus, the latest technologies help prevent breakdowns from which there was no escape before.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment