Error F43 in a Siemens washing machine

Modern Siemens washing machines are equipped with a smart self-diagnostic system - thanks to it, breakdowns of internal parts do not go unnoticed. Having detected a malfunction, the machine notifies the user about it. The explanation of error codes is given in the instructions. If the washing machine displays error F43, it means that problems have been identified with the Hall sensor. Usually in such a situation the cycle stops, since the “brain” of the machine does not receive data from the tachogenerator. Let's figure out what to do to reset the code and “reanimate” the machine.

Modern Siemens washing machines are equipped with a smart self-diagnostic system - thanks to it, breakdowns of internal parts do not go unnoticed. Having detected a malfunction, the machine notifies the user about it. The explanation of error codes is given in the instructions. If the washing machine displays error F43, it means that problems have been identified with the Hall sensor. Usually in such a situation the cycle stops, since the “brain” of the machine does not receive data from the tachogenerator. Let's figure out what to do to reset the code and “reanimate” the machine.

We make sure that the tachometer is broken

You can understand that the tachogenerator of a Siemens washing machine has failed by a number of external signs, and not just by error F43. The following “symptoms” indicate problems with drum spinning:

- the machine abruptly changes the rotation speed of the “centrifuge”, moving from high to low speeds, and this does not depend on the stages of washing;

- the drum speed acquired by the washing machine is much higher than that set by the program or user;

- the drum cannot spin up to the required speed, or stands still;

- things in the machine remain wet even after starting an intensive spin cycle.

What to do first? First, you need to make sure that this is not a short-term malfunction of the equipment. Therefore, turn off the Siemens washing machine, leave it for 20 minutes and then start the cycle again.

A faulty tachometer can lead to motor failure.

When you see fault code F43 on the display, there is no need to delay solving the problem. If you suspect a tachogenerator breakdown, it is better to start diagnostics as soon as possible.You can check the automatic machine yourself.

Where is the tachometer installed?

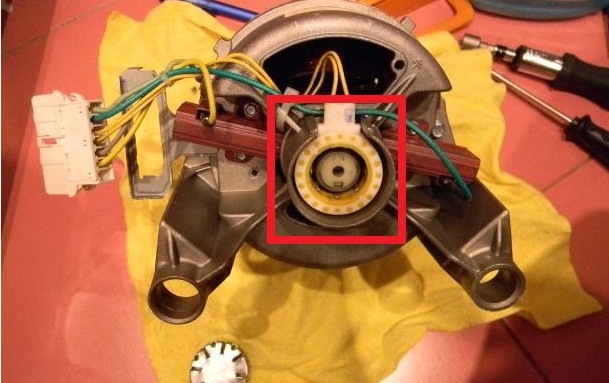

To check the tachogenerator, you need to understand where it is located in the Siemens washing machine and get close to the element. The Hall sensor is located on the rotating shaft of the electric motor. Therefore, it is necessary to partially disassemble the body of the “home assistant”: remove the back wall and tighten the drive belt. Before starting repairs, be sure to turn off the power to the machine and close the shut-off valve responsible for the water supply. Then you can disassemble the case: unscrew the screws securing the back panel. Access to the inside of the washing machine will open. The drum pulley and the drive belt stretched over it will immediately catch your eye. You need to remove the rubber band and find the engine - it is located below, under the tank.

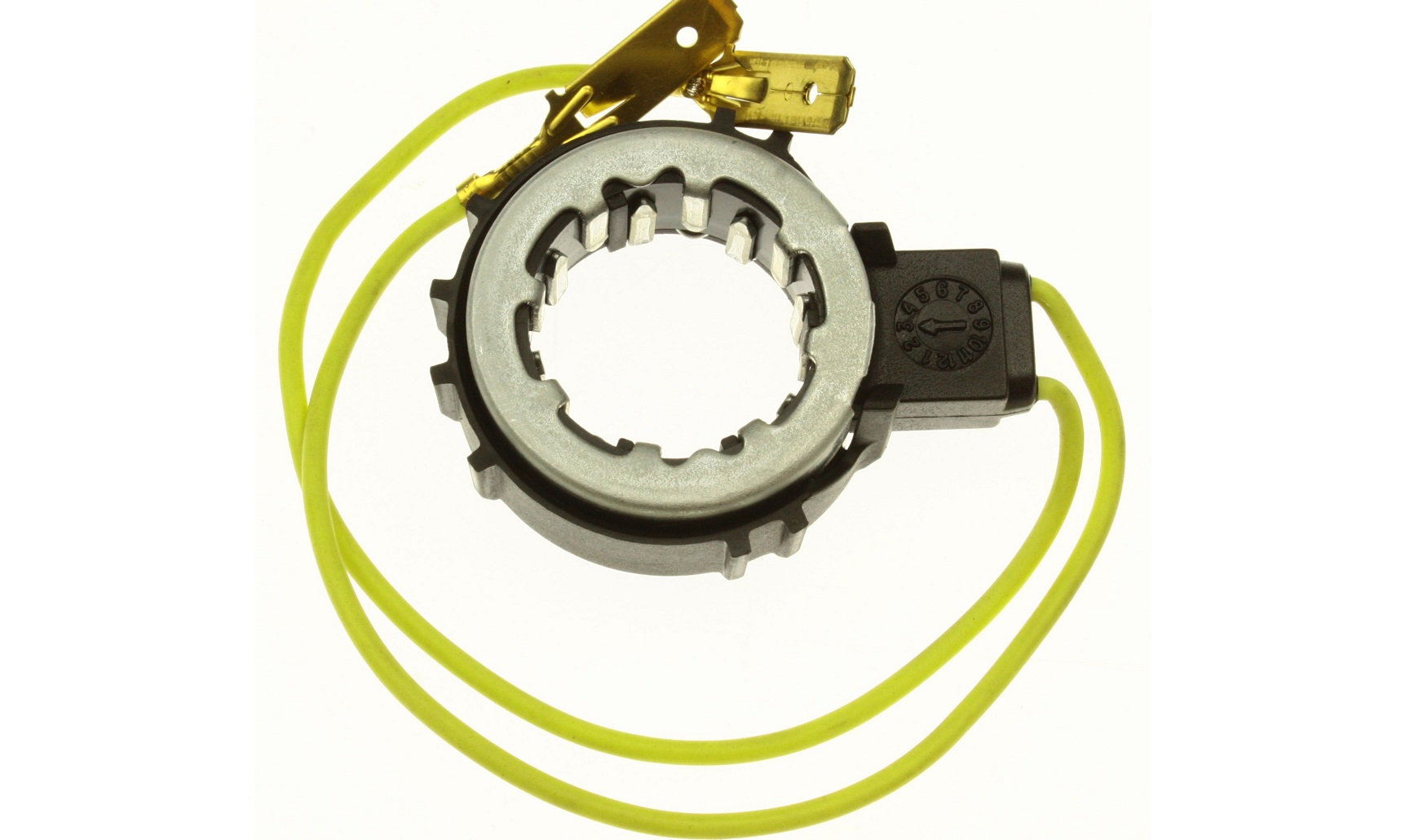

The tachogenerator is a small iron ring located on the motor shaft.

You should not try to unhook the Hall sensor; you must remove the entire engine. Let's figure out how to remove the electric motor from the housing and check the tachogenerator.

Testing the element

You can remove the electric motor and check the tachometer yourself, without the help of specialists. Having chosen to repair it yourself, it is important to strictly follow the instructions for action so as not to damage the automatic machine. The first thing you need to do is take a picture of the wiring diagram for connecting to the engine. This will help you avoid mistakes when reassembling the machine. Once the photo is taken, you can reset the contacts and begin removing the motor. The algorithm of actions will be as follows:

- Unscrew a couple of bolts that secure the engine to the housing;

- grab the engine, shake it left, right;

- Pull the part towards you sharply. The Siemens washing machine motor is quite heavy, get ready for it.

Inspect the Hall sensor to see if it is securely attached to the motor shaft. It happens that due to strong vibrations of the equipment, the contacts come off the tachogenerator and the clamps become loose. If this is the case, then restoring the fasteners and “tightening” the terminals will help correct the situation. When there are no visual defects, you need to test the part with a multimeter. The device should be switched to resistance measurement mode and its probes should be applied to the contacts of the tachometer. If the screen displays a value within 60-70 Ohms, then the tachogenerator is working.

The second way is to measure the current produced by the Hall sensor. To do this, start the multimeter in voltage mode, apply the tester probes to the contacts of the metal ring, and spin the motor shaft with your free hand. Normally, the device display should display a value within 0.2 Volts.

In fact, the tachogenerator of Siemens washing machines very rarely fails. Typically, problems with drum rotation are observed due to loose contacts or problems with the main control module. If during the test it was confirmed that the Hall sensor is fully operational, but the machine still displays error F43, you will have to check the wires and the board.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment