Error F17 in a Siemens washing machine

Any washing program launched on an automatic machine begins by filling the tank with water. The main control unit controls the liquid level by analyzing the readings transmitted by the pressure switch. If the tank is not filled with the required amount of water within the allotted time, the system will issue fault code F17. We’ll tell you how to deal with an error on a Siemens washing machine right now.

Any washing program launched on an automatic machine begins by filling the tank with water. The main control unit controls the liquid level by analyzing the readings transmitted by the pressure switch. If the tank is not filled with the required amount of water within the allotted time, the system will issue fault code F17. We’ll tell you how to deal with an error on a Siemens washing machine right now.

Let's start with the filter in front of the valve

Due to the poor quality of tap water, manufacturers of Siemens washing machines equip machines with a special filter designed to prevent debris and other particles from entering the system. Impurities contained in water often clog the flow filter mesh of the SMA filling valve.

The filter is placed in front of the filling valve, directly in the hole where the water intake hose is connected.

Often, the reason for the appearance of the code is a clogged plastic filter mesh. To clean the element, you do not need any special skills or knowledge; even a housewife who is not familiar with the structure of the washing machine can handle the job. To clear the blockage, do the following:

- Turn off the power to the Siemens washing machine, close the shut-off valve;

- Unscrew the inlet hose from the hole. Remember that there is always some liquid left in its cavity, so before unscrewing it is better to slip a rag under the joint. By unhooking the hose from the housing, you will have free access to the filter;

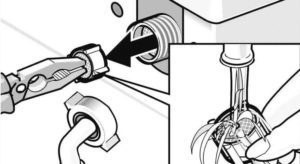

- Lightly pinch the filter mesh with pliers and pull it out of the cavity;

- Rinse the filter under running warm water.If you need more intensive cleaning, immerse the mesh in the prepared citric acid solution (250 ml teaspoon of acid) for half an hour or an hour. Monitor the temperature of the solution, it should be warm. Boiling water can deform the plastic, then you will have to buy a new filter;

- Install the clean filter mesh back to its original position until it stops. You can press the part using pliers;

- Screw in the washer's inlet hose.

After this, you can open the shut-off valve and make sure that the place where the inlet hose is connected to the machine body is not leaking. Plug in the equipment and select any washing mode. If error F17 is no longer displayed on the display, then the problem lies in a “clogged” filter.

Intake valve problems

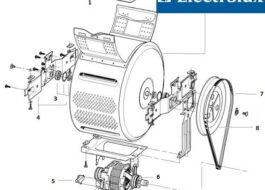

What to do if cleaning the filter mesh does not work? You will have to check the filling valve of the Siemens washing machine. It is installed directly under the top cover of the unit, attached to the rear wall. After removing the top panel, you will definitely see an element with several connected tubes through which the liquid enters the powder receptacle. The algorithm for repairing an intake valve with your own hands will be as follows:

What to do if cleaning the filter mesh does not work? You will have to check the filling valve of the Siemens washing machine. It is installed directly under the top cover of the unit, attached to the rear wall. After removing the top panel, you will definitely see an element with several connected tubes through which the liquid enters the powder receptacle. The algorithm for repairing an intake valve with your own hands will be as follows:

- remove the top cover of the case by unscrewing the pair of bolts holding it;

- Inspect the solenoid valve; it may have visible damage.

If the visual inspection is uninformative, you will have to remove the valve. To do this, open the metal clamps and disconnect the pipes connected to the valve. Disconnect the power supply from the element. Before removing the wires, it is advisable to photograph the connection diagram to avoid mistakes during reassembly. All that remains is to unscrew the bolts securing the part to the wall and remove the valve.

It is recommended to carry out diagnostics of the inlet valve over a sink, bathtub or empty container so as not to wet the floor covering.

First, inspect the device and its pipes for blockages. Then connect the inlet hose to the valve and start the water supply. A properly functioning element will not allow leakage. If there is leakage, a new valve will have to be installed.

Further testing should be done with extreme caution. A voltage of 220 V is applied to the coils of the element. During this procedure, the section should open up and fill with water. This testing method is dangerous, since a short circuit may occur when liquid and electricity come into contact.

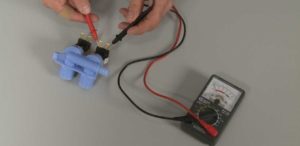

A multimeter will help you accurately understand whether the filling valve needs to be replaced or not. The measuring device is switched to resistance determination mode. The tester probes are applied one by one to the valve winding. The working sensor should produce a resistance of about 3 kOhm. There is no point in repairing the solenoid valve. It is necessary to purchase a new spare part and replace the failed element. The algorithm for action is as follows:

- secure the valve to the MCA wall with a fixing bolt;

- connect the wires to the required connectors;

- attach the hoses in place using fixing clamps;

- Replace the top panel of the case, tighten the retaining screws.

By following this sequence of actions, you can easily replace the filling valve, the breakdown of which could cause error F17. After completing the steps, turn on the Siemens washing machine and run a test wash.

Let's check the pressure switch

The display of error F17 may occur due to a faulty pressure switch. The level sensor measures the volume of water in the tank; if it does not function correctly, an incorrect signal is transmitted to the control module, and the “brain” blocks the operation of the SMA. To diagnose the pressure switch, you need:

- unplug the power cord of the Siemens washing machine from the outlet;

- turn off the inlet valve responsible for drawing water from the communications;

- remove the cover of the machine body;

- find the pressure switch. It is usually attached to the side wall of the unit;

- take a tube with a diameter corresponding to the size of the pressure switch fitting;

- disconnect the pressure hose, first loosening the clamp;

- Place the tube against the fitting and blow lightly into it.

A working level sensor will produce one or three characteristic clicks. If the device does not make any sounds, it can be stated that it is broken.

Inspect the pressure switch for defects and mechanical damage. Make sure its hose is not clogged. If you find contamination in the cavity, be sure to rinse the hose under the pressure of warm water.

If a visual inspection does not allow you to clearly understand that the pressure switch is faulty, you can check the sensor with a multimeter. The device is put into resistance determination mode, its probes are applied to the contacts of the pressure switch relay. The values on the multimeter display will change when the contacts are triggered. If the readings remain initial, the level sensor does not work. To understand which contacts of the pressure switch you need to connect the multimeter to, first study the electrical diagram of the device.

There is no point in repairing a non-functioning water level sensor. It is better to buy a new part that matches your Siemens machine model. Moreover, the cost of the pressure switch is low.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment