Error F06 in Whirlpool washing machine

Household appliances tend to break down at the wrong time. This especially applies to washing machines. Fortunately, most modern washing machines are equipped with an automatic diagnostic system. The machine itself detects a malfunction and shows it on the display in the form of a code. Let's try to figure out what to do if the Whirlpool washing machine issues code F06.

Household appliances tend to break down at the wrong time. This especially applies to washing machines. Fortunately, most modern washing machines are equipped with an automatic diagnostic system. The machine itself detects a malfunction and shows it on the display in the form of a code. Let's try to figure out what to do if the Whirlpool washing machine issues code F06.

What does the code say?

Sometimes fault code F06 appears on the display when the main board fails. Therefore, first you should always try to restart the machine by turning it off and then turning it on again after 10-15 minutes. If the equipment was unable to reset the error, it means that the code indicates the absence of a signal from the tachometer.

The tachogenerator is installed on the engine rotor. It allows you to read the speed of the motor and control the number of its revolutions. The faster the engine shaft rotates, the higher the voltage supplied to the tachometer, information from which is transmitted further to the main control board. If the washing machine displays error F06, there may be two main reasons for this:

The tachogenerator is installed on the engine rotor. It allows you to read the speed of the motor and control the number of its revolutions. The faster the engine shaft rotates, the higher the voltage supplied to the tachometer, information from which is transmitted further to the main control board. If the washing machine displays error F06, there may be two main reasons for this:

- breakdown in the sensor assembly - displacement of the spring washer of the coil;

- a breakdown in the circuit between the TAKHO-ED unit and the control panel.

If the sensor itself fails, you need to replace the washer. In the second case, you will need to correct defects in the electrical circuit. Let's start the diagnostics by disassembling the machine.

Finding the tachometer

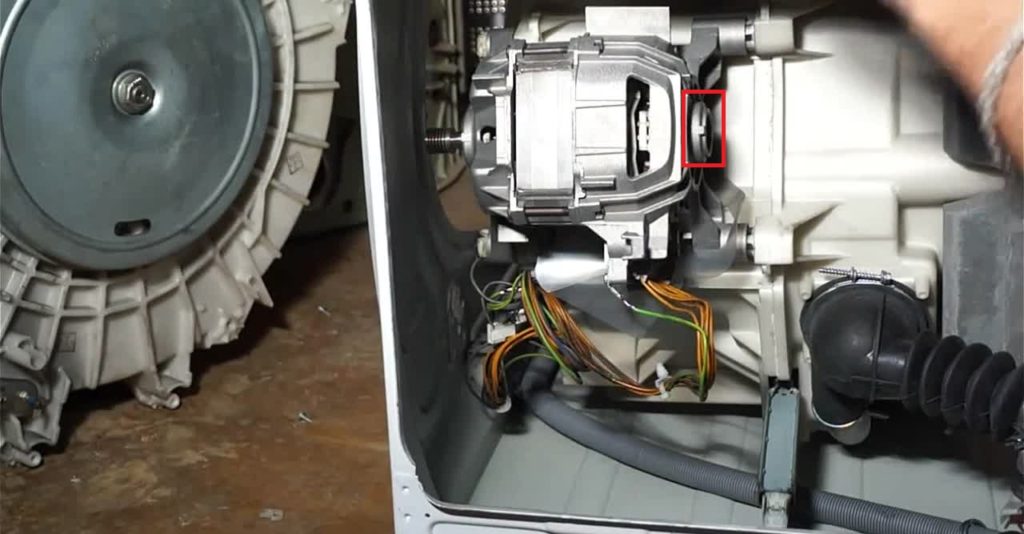

In all Whirlpool washing machine models, the tachogenerator is located on the rotating motor shaft. To get to the motor, you need to remove the rear wall of the unit (by unscrewing the fasteners and prying the panel with a screwdriver) and remove the drive belt. First turn off the power to the equipment and disconnect it from the water supply.

Important! Take your time to disassemble the machine, first carefully check the spin mode button - if it is pressed inward, the problem may lie there.

On the engine shaft you will see an iron ring with two wires - this is the tachogenerator or Hall sensor. It cannot be dismantled without removing the engine from the machine. Therefore, if you do not have experience in electrical installation, it is better to entrust the work to a specialist. Otherwise, during experimental repairs, there is a high risk of not correcting, but of aggravating the problem.

How to test a tachometer?

If you decide to carry out further manipulations, we work strictly according to the instructions. We mark all the wiring of the electric motor with a marker or take a photo with our phone. This will avoid errors when reassembling the Whirlpool washing machine.

- Unscrew the fasteners holding the electric motor.

- Gently rock and pull out the engine.

- After dismantling, we inspect the wiring and tachometer.

It is important to check the position of the latches and the integrity of the contacts. If you see a loose or loose fastener, you need to restore it in place. What to do if there is no obvious damage?

The next step is testing the tachogenerator. There are two ways to check the functionality of this part. First: turn the multimeter on to ohmmeter mode, apply the probes to the contacts. Normally, the sensor resistance is 60 ohms. Second: current measurement. To do this, set the voltmeter mode on the tester, connect the probes to the contacts and accelerate the motor with the second hand. If a figure of 0.2 V appears on the device, the sensor is in good condition.

Replacing a damaged element will not be difficult. You should completely disconnect the wiring and remove the cover of the part, secured with a conventional latch.Then unscrew the fasteners, remove the tachogenerator and install a new one in its place.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment