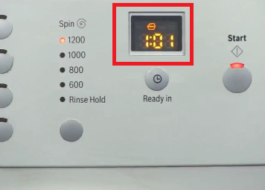

Error F03 in Leran washing machine

What does error F03 indicate in a Leran washing machine? This code indicates problems with the drain. The washing machine cannot remove waste water from the tank into the sewer.

What does error F03 indicate in a Leran washing machine? This code indicates problems with the drain. The washing machine cannot remove waste water from the tank into the sewer.

Typically, a fault code is displayed on the display in the middle of the cycle, when the machine finishes washing and starts rinsing. In some cases, the error appears immediately after turning on the SMA. Let's figure out what to do if F03 is displayed on the washing machine display.

Why doesn't the sewage go away?

Having noticed error F03 on the display, you need to find the cause of the malfunction. The problem could be a clogged garbage filter, a burnt-out pump or a failed electronic module. What complicates the situation is that “dirty” problems have similar “symptoms”. Therefore, you will have to check all the elements responsible for draining one by one.

Draining sewage from the SMA becomes difficult due to internal or external blockages, problems with drainage hoses, or breakdowns of the pump and control module.

So, the cause of an incorrectly functioning drain can be:

- a blockage in the siphon or sewer pipe (to rule out a problem, check how the water drains from the sink or bathtub);

- internal blockage of elements of the drain system (we are talking about a garbage filter, a drain hose, a pipe connecting the tank and the pump);

- faulty pump. A broken pump makes a lot of noise when it tries to pump out water, but cannot send it to the sewer. The part breaks due to natural wear or short circuit. Sometimes the reason lies in debris wrapped around the impeller blades;

- faulty electronic module.The control unit may fail due to manufacturing defects, power surges, short circuits, moisture on the board, or a regular technical “glitch”;

- incorrectly selected drain hose. Leran washing machines, like machines from any other manufacturer, have pumps of a certain power. If, instead of a standard hose 1.5 meters long, you connect a 2-3 meter corrugated pipe to the device, the pump will not cope with its task and will not be able to pump water into the sewer.

You can deal with most problems yourself. The help of a specialist will be required if the problem is a damaged control module. Let's figure out where to start repairing a Leran machine that displays error F03.

First, remove the waste water

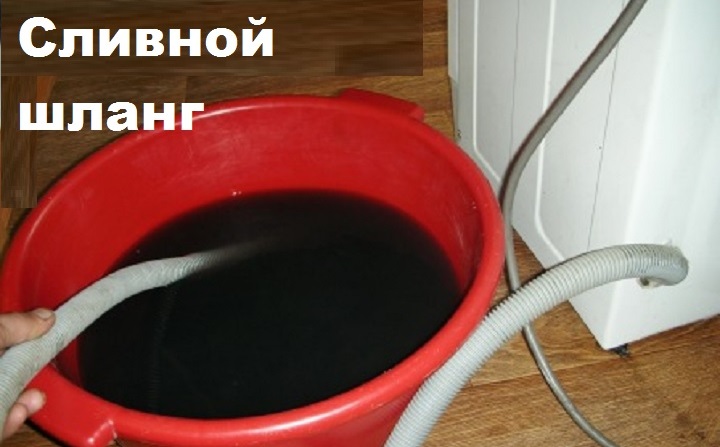

If an automatic machine generates a fault code in the middle of a cycle, it means that it is “stuck” with a full tank of water. At the first stage, you will need to drain the water from the washing machine and remove the laundry from the drum. There are three options for forced draining:

- through a garbage filter;

- through the emergency drain hose;

- through the drain hose.

It is easier and faster to drain the water through the main hose. Most Leran washing machines do not have a check valve in the sleeve, so there will be no “siphon effect”. It is enough to lower the corrugation below the level of the tank, and the water will flow by gravity into the sewer. After unlocking the UBL, open the drum door and remove the wet laundry from the machine.

Some Leran models have an emergency drain hose. In this case, it is recommended to drain the water through it. The pipe is located at the bottom of the housing, behind the technical hatch door, near the garbage filter.

And the last option is to drain the water through a filter. In this case, the algorithm of actions will be as follows:

- disconnect the SMA from the network and water supply;

- prepare a short but capacious container to collect water;

- open the technical hatch and find the garbage filter;

- cover the floor near the washing machine with rags;

- place a container under the machine to collect water, in the area where the garbage filter is located;

- turn the “trash can” plug half a turn, wait until some of the water drains out;

- Unscrew the filter completely.

If the garbage filter is unscrewed and the water does not drain out, then the cause is a clogged drain pipe coming from the tank.

Then you will have to unhook the drain pipe. After emptying the washer, you can begin troubleshooting. We'll tell you about further actions.

Troubleshooting

An empty and de-energized washing machine can be repaired. If you drained the water through the drainage sleeve or emergency pipe, you will still have to unscrew the garbage filter. The elements of the drain system are checked in the following order: “trash can”, hoses, impeller, pump.

First of all, the filter element is inspected. Often scale and limescale accumulate on the spiral. If there are deposits, they need to be cleaned off.

The filter also stops passing water when there are foreign objects in it - socks, coins, matches, paper. Clean the coil.

Be sure to look into the filter seat. Debris and dirt also accumulate in the hole. Wipe the walls with a damp cloth.

Next, the main drain hose of the machine and the drain pipe connecting the tank to the pump are probed. If seals are noticeable, you will have to disconnect and wash the elements.

The operation of the drain pump is ensured, among other things, by the impeller. When hair and threads get wrapped around the blades, the pump stops functioning. Therefore, shine a flashlight on the filter seat and clean the impeller of debris.

If the problem is definitely not clogged, you need to check the pump. To get to the pump, you will have to turn off the power to the machine, lay it on its side and remove the bottom. Then the bolts securing the part are unscrewed and the element is removed from the body.

It is usually difficult to visually determine whether the pump is working properly. Pump diagnostics are performed with a multimeter. A burnt-out part cannot be repaired; new components will have to be supplied.

Will have to replace the pump

If, before displaying fault code F03, the machine was making a loud noise while trying to drain water, in 99% of cases the pump will be the culprit. A broken pump cannot be repaired; the part will have to be replaced. The algorithm of actions will be as follows:

- de-energize the SMA;

- disconnect the drain and inlet hoses from the machine;

- lay the washer on its side (on the side where the powder receptacle is located);

- disconnect the housing tray;

- unhook the pipes and wiring from the old pump, dismantle the part;

- fix the new pump in place, connect hoses and wires to it;

- screw the bottom and return the MCA to the vertical position.

Next, a test wash starts. The water should start going down the drain. If replacing the pump does not help, you will have to check the control module. It is better to entrust this work to a master.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment