Error F01 in Leran washing machine

Progress does not stand still, so today it is very easy to understand the situation why household appliances suddenly stopped working properly. Error F01 in a Leran washing machine appears in a situation where there is no water supply to the tank to start the working cycle, which is why washing cannot start. Let's look at the reasons for the lack of liquid supply to the tank, and how to deal with them at home.

Progress does not stand still, so today it is very easy to understand the situation why household appliances suddenly stopped working properly. Error F01 in a Leran washing machine appears in a situation where there is no water supply to the tank to start the working cycle, which is why washing cannot start. Let's look at the reasons for the lack of liquid supply to the tank, and how to deal with them at home.

Possible reasons for the code to appear

Before you begin troubleshooting the problem yourself, you need to conduct a thorough diagnosis to understand why the F01 fault code appeared in the first place. Such an error could arise either due to an ordinary bend in the inlet hose, or due to a failure of the SM control module. Let us list the main reasons for the failure of the water supply function in the Leran “home assistant”.

- Damage to the inlet valve. If this is the problem, then the problem signals will appear even before the fault code appears. At the first stage, you may notice that the washing powder is not completely washed out of the cuvette, which indicates damage to the valve. To check the element, you need to apply 220 Volts to the solenoid valve, and if the part closes with a characteristic click, then everything is in order. Be sure to check the two valves, and if they both do not respond during the test, replace them.

- Clogged inlet grid. One of the most common situations is considered to be a banal blockage of the filter mesh. Because of this, a loud buzzing sound will appear, and the water will take much longer to fill than usual.

- The coarse filter is clogged.The solution to this problem is similar to that described in the previous paragraph - thoroughly cleaning the filter from all contaminants.

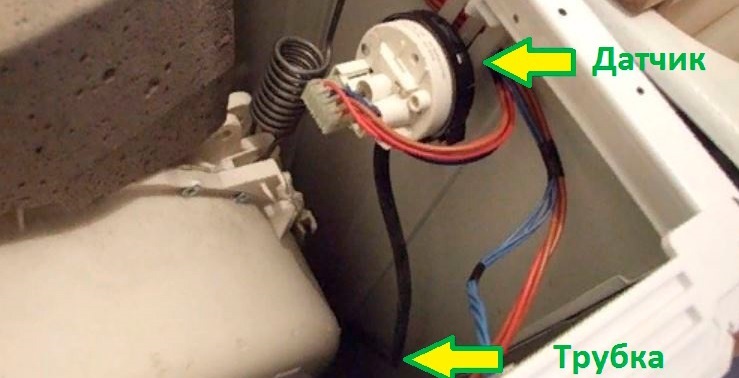

- Damage to the pressure switch. This part controls the water level in the system, so if this element fails, the control module will not be able to obtain information about the amount of liquid collected in the tank. You need to carry out a simple test of the sensor, for which you need to disconnect the pressure switch tube and blow into the wire. If you hear one or two clicks, then the part is working; if not, then the pressure switch will have to be replaced.

Just in case, additionally check the pressure switch wire, because it could be clogged with fabric fibers or cobwebs if the washing machine has not been used for a long time.

- SM control module malfunction. The most important element of the washing machine, which is also called the “brain” of the system, often suffers due to damage to the triacs. If these elements are burned out, then you do not need to replace the entire control module, but only install new triacs on the board. It is not recommended to do this yourself - it is better to entrust the work to the service center specialists.

- Damage to the hose that connects the pressure switch and the tank of household appliances. Over time, the hose loses its tightness, which is why air leaks.

- Poorly closed hatch door. In this situation, even repairs are not needed, because if the door is not tightly closed, then the UBL cannot block the lock, and the control module will not allow the start of the operating cycle.

- Pump failure. Finally, the lack of water intake may be due to damage to the drain pump. It is possible to repair it, but it is much easier to simply replace the pump.

As you can see, there is only one fault code, but there are so many reasons for its occurrence that without detailed diagnostics it is impossible to understand the breakdown.

Looking for a problem

Having decided to deal with the problem yourself, first of all, disconnect the Leran washing machine from all communications. Do not skip this step under any circumstances, as these are standard precautions. If water does not fill the tank, but the machine hums intensely, then follow our instructions.

- First, make sure that the shut-off valve is open so that water can flow into the system. Cover it to keep it out of the way during diagnostics and repairs.

- Disconnect the inlet hose from the device and drain the remaining waste fluid from it.

- Check the filler hose for damage and that it has not been kinked.

These are the first three actions that need to be performed if there is no water supply. If you are convinced that everything is in order, then you should carefully examine the filter element located inside the inlet hose. To check the mesh you need:

- remove the hose;

- examine the valve system in which the mesh is installed. The filter has a special indentation that needs to be fixed with pliers and gently pulled towards you to remove the filter element;

- rinse the filter under a powerful stream of hot water;

- install the mesh in place using the same pliers.

The last stage of diagnosis will be checking the coarse filter, which is most often installed after the tap. This procedure will be a little more complicated than the previous one, because you will need two keys in order to simultaneously hold the connection point with the valve and unscrew the bolt. When everything is ready, place a basin under the tap so as not to flood the floors or neighbors below. Under powerful water pressure, the filter can be cleaned of any contaminants.

Intake Valve Replacement

Any repair of an expensive “home assistant” seriously impacts the family budget, which is why many try to solve the problem at home. This makes sense, especially if the fault code F01 appeared due to damage to the water supply valve. What to do in this case?

- Disconnect the Leran washing machine from all communications.

- Remove all hoses attached to the back of the machine.

Place any water container under the connection point, as liquid accumulates in the hoses.

- Detach the device cover by first removing the latches.

- Take a photo of the correct connection of the wires to the valve so that you can have an example at hand later, disconnect the wiring.

- Using pliers, remove the fasteners from each and four hoses, under which you need to place a water container in advance. It is also better to take a photo of the correct location of the hoses.

- Remove the screw securing the valve.

- Remove the damaged solenoid valve from the CM.

- Place the new valve in place of the old element and secure it with a bolt.

It is better to buy original Leran parts rather than analogues, for which you need to either remember the exact name of your washing machine model, or take the damaged valve to the store as an example.

- Reconnect the hoses that you removed in the previous steps, and then secure them with clamps.

- Based on the photo, connect all the wires to the element.

- Reinstall the top panel of the washing machine, securing it with self-tapping screws.

- Connect the hoses to the rear panel of the CM.

At this point, the repair will be completed, and all you have to do is connect the equipment to the power supply and water supply, open the shut-off valve and start the test operating cycle.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment