Error E5 in Gorenje washing machine

What kind of failure does error E5 indicate in a Gorenje washing machine? This fault code indicates problems with the electric motor. To fix the problem, you will have to replace the SMA motor. We'll tell you how to do it yourself.

What kind of failure does error E5 indicate in a Gorenje washing machine? This fault code indicates problems with the electric motor. To fix the problem, you will have to replace the SMA motor. We'll tell you how to do it yourself.

Checking the engine of the Gorenje washing machine

If you notice fault code E5 on the washing machine display, there is no need to panic. Turn off the power to the device and disconnect it from communications. Next, you will have to remove the electric motor from the housing and perform diagnostics on it.

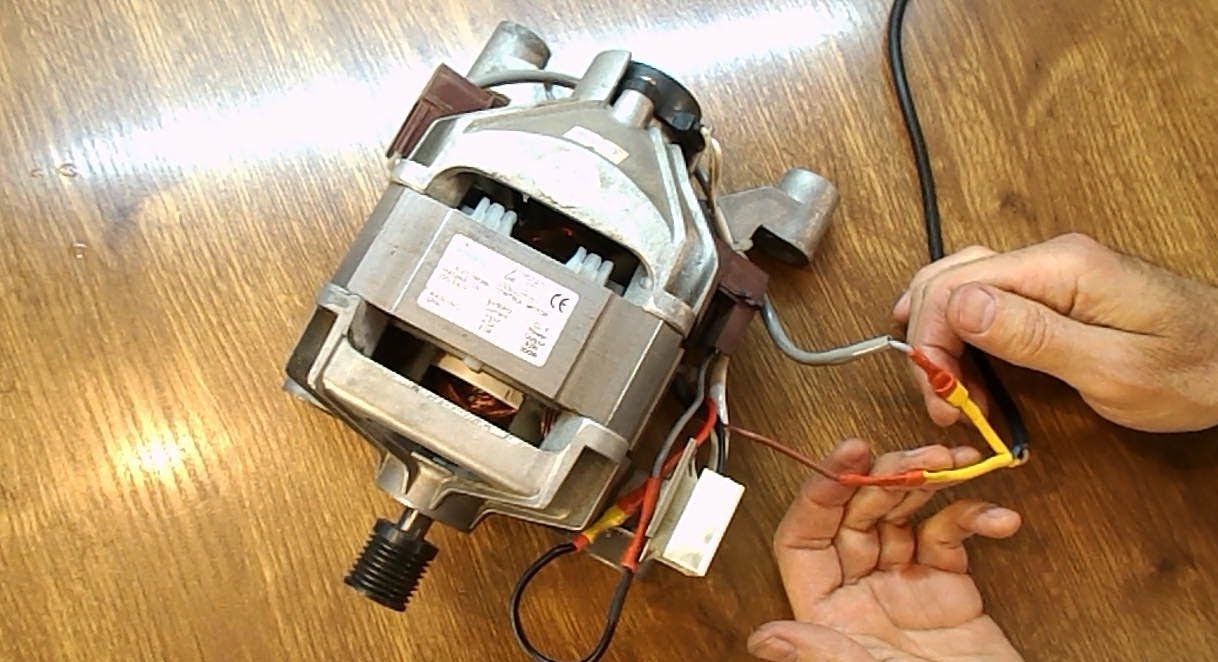

Gorenje automatic washing machines have commutator-type motors.

All Gorenje SMAs are collector type. An integral part of the washing machine is the drive belt, which starts the rotation process. An elastic band connects the motor pulley and the drum.

As for the internal structure of the commutator engine, under the body there are a pair of brushes, a rotor, a stator, lamellas and a winding. On top there is a Hall sensor that controls the speed of the motor. There are two ways to check the operation of the electric motor, but first the element will have to be removed from the machine. For this:

- de-energize the MAS, unhook the drain and inlet hoses from the body;

- push the machine to the center to have access to the back of the case;

- Unscrew the screws securing the back panel and remove the wall;

- remove the drive belt from the pulley;

- take a photo of the wiring diagram for the motor;

- disconnect all wires from the engine;

- Unscrew the bolts holding the engine;

- Rocking the engine, pull it out of the CMA housing.

What to do next? The first diagnostic method is to connect the wires of the stator and rotor windings and apply a voltage of 220 Volts to them.If the motor starts to rotate, then the engine is functioning.

This diagnostic method has disadvantages:

- it is impossible to test engine operation in different modes;

- the device, due to direct connection to the electrical network, may overheat (to prevent this, it is better to include a ballast in the circuit, in the form of a heating element).

Another way to check the motor winding is to test it with a multimeter. The device is switched to resistance measurement mode. A zero or one on the device screen will indicate a break or short circuit.

This is the first stage of diagnosis. Next, you need to check other parts of the commutator one by one, namely brushes and lamellas. Electric brushes need to be changed every 2-3 years - they are subject to wear. We'll tell you how to understand whether graphite rods need to be replaced.

Graphite brushes need to be replaced

It is very easy to check electric brushes with your own hands. They are located on the sides of the motor housing. The rods smooth out the friction force coming from the engine, so they wear out quite quickly. The algorithm of actions will be as follows:

- unscrew the fixing bolts;

- compress the spring and remove the brushes;

- disassemble the body of each electric brush;

- Assess the degree of wear of the graphite rods.

If the length of the carbon tips is less than one and a half centimeters, the brushes need to be replaced.

Replace electric brushes in pairs, even if one graphite rod is worn out and the other is not. Components are purchased for a specific Gorenje SMA model. Installing new elements is done in reverse order.

Checking other engine components

The lamellas are responsible for transmitting current to the rotor. They are fixed on the motor shaft. When the motor jams, the plates are destroyed and peeled off.If the damage is minor, then you don’t have to completely replace the engine, but simply repair the elements using fine sandpaper and a lathe.

The repair will consist of removing peeling and burrs from the lamellas. The work must be done carefully so as not to further damage the plates. If the defects are severe, the engine will need to be replaced.

The SMA electric motor cannot function normally if there are problems with the winding. Trying to accelerate, the engine will overheat. The temperature sensor, having detected too high a temperature, will urgently interrupt the operation of the system, and the control module will display a fault code on the display E5. If the problem is not corrected, then everything will repeat in a circle until the thermistor fails.

Checking the engine is done with a multimeter:

- the tester is switched to resistance measurement mode;

- the probes of the device are applied to the lamella;

- The readings on the device screen are evaluated.

Normally, the motor winding should produce a resistance of 20 to 200 Ohms. If the value is less, there is a short circuit. When the number is higher, we can talk about a break.

Checking the stator is also performed with a multimeter, but switched to buzzer mode. The probes are alternately applied to the stator winding. If the tester is silent, everything is fine. A characteristic squeak will tell you about a break. In this case, repairs will not help; the engine will need to be replaced.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment