Error E32 in a Bosch washing machine

Not all signals from the self-diagnosis system directly indicate a breakdown. Some ciphers only warn the user about “symptoms” and violated operating conditions of the equipment, which may lead to problems in the future. In this case, the matter is not limited to the code on the display: the machine stops and does not allow you to continue washing. The warnings also include error E32 in the Bosch washing machine. We suggest you figure out what is hidden behind the combination and how to deal with it.

Not all signals from the self-diagnosis system directly indicate a breakdown. Some ciphers only warn the user about “symptoms” and violated operating conditions of the equipment, which may lead to problems in the future. In this case, the matter is not limited to the code on the display: the machine stops and does not allow you to continue washing. The warnings also include error E32 in the Bosch washing machine. We suggest you figure out what is hidden behind the combination and how to deal with it.

Purpose of this code

If error code E32 is displayed on a Bosch washing machine, it means that the self-diagnosis system has detected excessive swinging of the drum during the spin cycle. In simple words, the machine reacts to the first signs of imbalance and forcibly stops the cycle, preventing damage to the crosspiece, tank and other structural elements. All this allows you to reduce the risk of breakdown to a minimum.

Error E32 indicates problems with drum imbalance.

All modern models from Bosch and other major brands of household appliances equip washing units with built-in imbalance protection. Especially if the maximum spin speed exceeds 1000 rpm. Thanks to this function, the machine immediately responds to drum imbalance by displaying error “E32”.

A detailed explanation of “E32” can be seen in the factory instructions. Here are the basic rules for using a washing machine, as well as the reasons for the imbalance and recommendations for eliminating it on a specific model. As a rule, the information is typical and applies to most Bosch, but there are exceptions.

In order not to damage the washing machine to the point of damaging the drum-tank assembly and not to invest in expensive repairs, it is better to immediately respond to E32. Experience shows that excessive swaying is caused by non-compliance with the maximum or minimum load weight. The instructions and the price tag must indicate the capacity of the machine in kilograms. Please note that the standards are given for dry cotton materials. Wool and synthetics are heavier than cotton, so you can additionally focus on the filled volume - no more than 2/3.

Why else does imbalance occur?

Most often, overweight or underweight laundry leads to imbalance. In the first case, the drum becomes too heavy and goes astray from the intended “orbit”, and in the second, things become crumpled and upset the balance. Fixing the failure is simple: just open the hatch, take out excess clothes or add more.

It’s more difficult if the problem with E32 is caused by improper installation of the washing machine or damage to the machine’s design. So, five breakdowns and failures lead to imbalance at once.

- Unremoved shipping bolts. Such fasteners are necessary for the safe transportation of the washing machine, as they fix the drum in a stationary position. Before the first wash, all 4 latches must be removed, and plastic plugs are inserted in their place. If you start a tank clamped with screws, the engine will try to spin it, which will lead to shaking, “jumping” and internal mechanical damage. Moreover, such breakdowns are not covered by a free warranty, as this is a serious violation of Bosch operating rules.

It is prohibited to operate the washing machine with the transport seals not removed - this will cause severe mechanical damage to the internal structure of the machine!

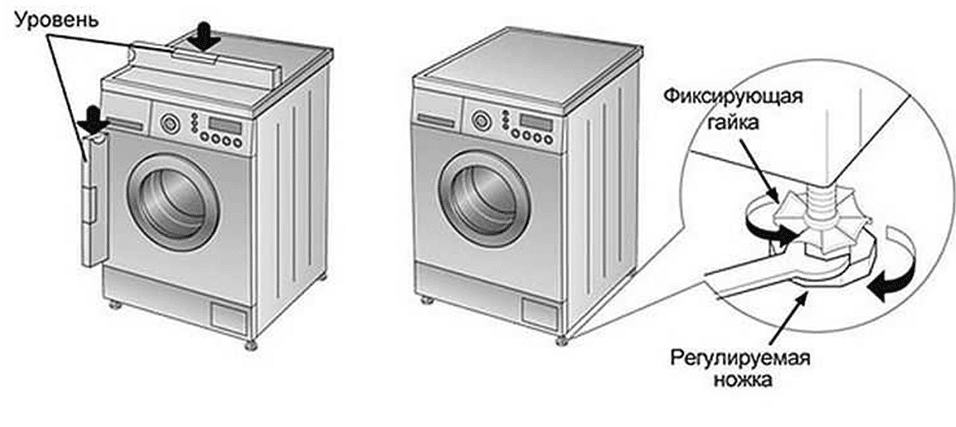

- Incorrect installation of the washing machine. According to the instructions, the machine must be placed on a flat and hard surface - concrete or tiles.. The more stable the equipment is, the more vibration is suppressed and the less likely it is to become unbalanced, which is why wood, linoleum and carpet are considered poor surfaces. It is also important to level the unit to the building level by adjusting the height of the legs. It is recommended to use special anti-vibration attachments and mats.

- Destroyed bearing assembly. If you don’t know what to do with damaged bearings, then it’s better to entrust them to professionals. The work is long, difficult and costly.

- Damaged shock absorption system. The drum in the washing machine is suspended, and the springs and shock absorbers holding it are designed to smooth out the pressure of the centrifugal force and suppress outgoing vibrations. However, if the racks are worn out or fasteners are loose, the dampers do not fully perform their functions, which leads to imbalance. It’s easy to check the integrity and elasticity of the shock absorption: just remove the top cover, press on the tank and evaluate its behavior. If the tank jumped up and fell into place, then everything is in order; if chaotic rolling begins, replacement is required.

- Damaged counterweights. Designed to suppress vibrations of the accelerating drum and counterweights are concrete blocks located on the top, bottom and sides of the body. They add weight to the washer, increasing its stability. But if the concrete is destroyed or deformed, then the balance is upset.We remove the cover, check the integrity of the stones and try to repair it: tighten the bolts and cover the cracks with PVA glue.

The imbalance protection function is often called the “self-preservation instinct” of the washing machine. Here, as in nature: the machine senses the approach of danger, anticipates the consequences and leaves the distance, reducing the risk of breakdowns. The owner needs to react to the Bosch signal in a timely manner and restore the balance of the drum.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment