Error E21 in a Bosch washing machine

Sometimes users encounter this problem: the machine is turned on, the desired cycle is started, but after a while the drum stops and the washing machine freezes. In this case, fault code E21 lights up on the device display.

Sometimes users encounter this problem: the machine is turned on, the desired cycle is started, but after a while the drum stops and the washing machine freezes. In this case, fault code E21 lights up on the device display.

What does error E21 indicate in a Bosch washing machine? How is the code deciphered? Which MCA nodes will need to be checked? Let's look into the nuances.

Decoding the code

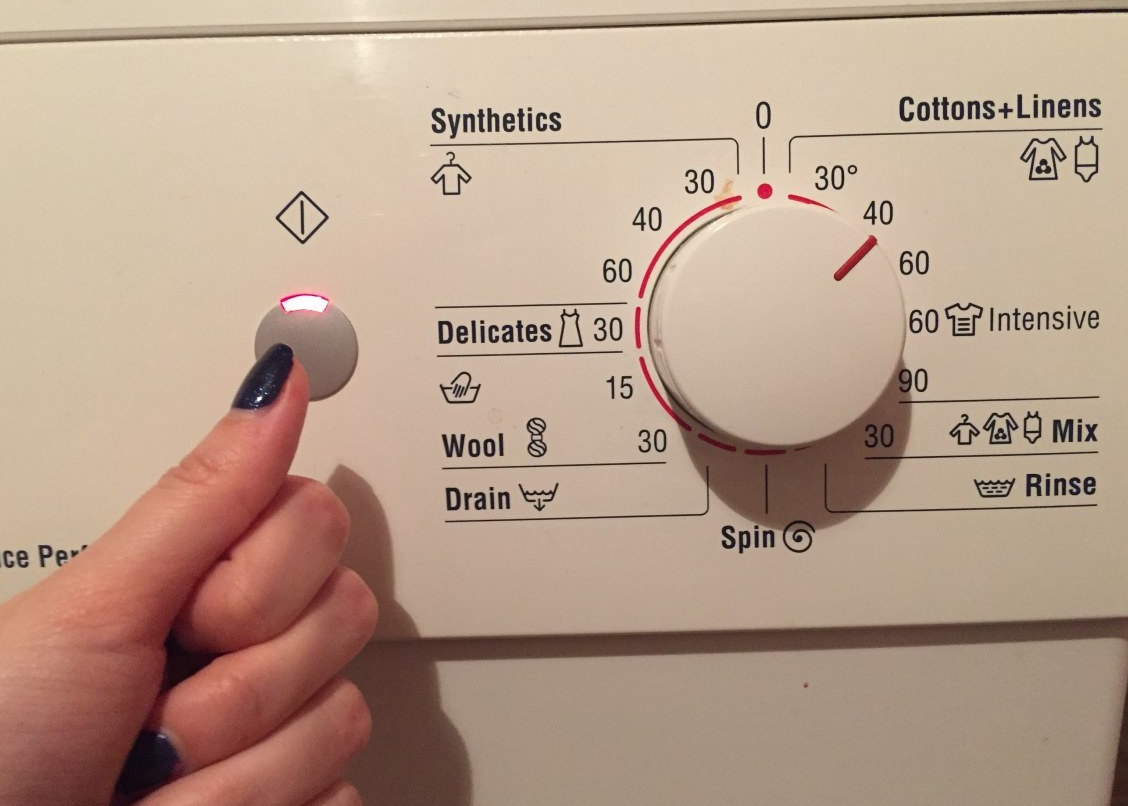

All modern Bosch washing machines are equipped with an automatic self-diagnosis system. Having detected a breakdown, the machine immediately displays the corresponding fault code on the display. SMAs without a display notify the user of the problem by flashing indicators on the control panel.

Which indicators on the dashboard light up depend on the SMA model. For example:

- on Bosch Classic, code E21 corresponds to the flashing of the “Rinse” light;

- on Bosch Maxx 4 the “Wash Ready” and “Cycle End” LEDs will inform you about the problem; they will flash simultaneously;

- Bosch Maxx 5, 6 and 7 will indicate error E21 by flickering the “Spin” and “Rinse” indicators.

You can see the explanation of all possible errors in the instructions for the Bosch washing machine.

If you notice the incorrect behavior of the “home assistant”, immediately turn off the power to the washing machine. Only after this can you begin to diagnose the equipment. What to do next, what details of SMA to pay attention to?

Where did it come from?

What could be the reasons for this error appearing on the display? The instructions interpret the code E21 as the inability to rotate the drum. The washing is completely blocked, the machine starts an emergency drain.

Error E21 can be triggered by:

- strong surge in power supply;

- a foreign object stuck between the drum and the tank;

- a broken or broken drive belt;

- broken motor;

- broken tachometer;

- incorrectly functioning electronic module.

Diagnosis of any error begins with problems that are easiest to check. First you need to make sure that this is not a trivial system failure. Rebooting is easy to do with your own hands, to do this:

- turn off the machine with the button;

- unplug the power cord from the outlet;

- let the washer sit for 15-20 minutes;

- turn on the SMA again.

If the error disappeared and the machine completed the cycle as if nothing had happened, then we can talk about a one-time system failure. If the code appears again, you will have to look for the cause of the malfunction. First of all, the voltage in the electrical network is checked.

Blame the power grid

Sometimes error E21 is caused by insufficient voltage in the electrical network. You can check this assumption using a multimeter. The algorithm of actions will be as follows:

- unplug the machine's power cord from the outlet;

- use a multimeter to check the voltage at the point;

- compare the calculated readings with the normative ones (they are written down in the SMA passport).

In the case when the voltage really “jumps”, you will have to connect a stabilizer to the electrical network. Without having the skills to work with electricity, it is better to entrust this matter to a specialist.

If fluctuations and surges are a frequent occurrence in your home electrical network, it is better not to delay installing a voltage stabilizer.

Dangerous object stuck in tank

If you notice code E21 on the Bosch washing machine display, be sure to check the drum. Open the loading hatch and rotate the container by hand.If the centrifuge moves with difficulty, or even stands still, it is likely that it is blocked by small debris that has gotten inside: a bra wire, a coin, a key, etc.

To eliminate the error, you will have to remove the foreign object from the washer. For this:

- de-energize the SMA;

- remove the cover from the housing;

- drain the remaining water from the system by unscrewing the garbage filter;

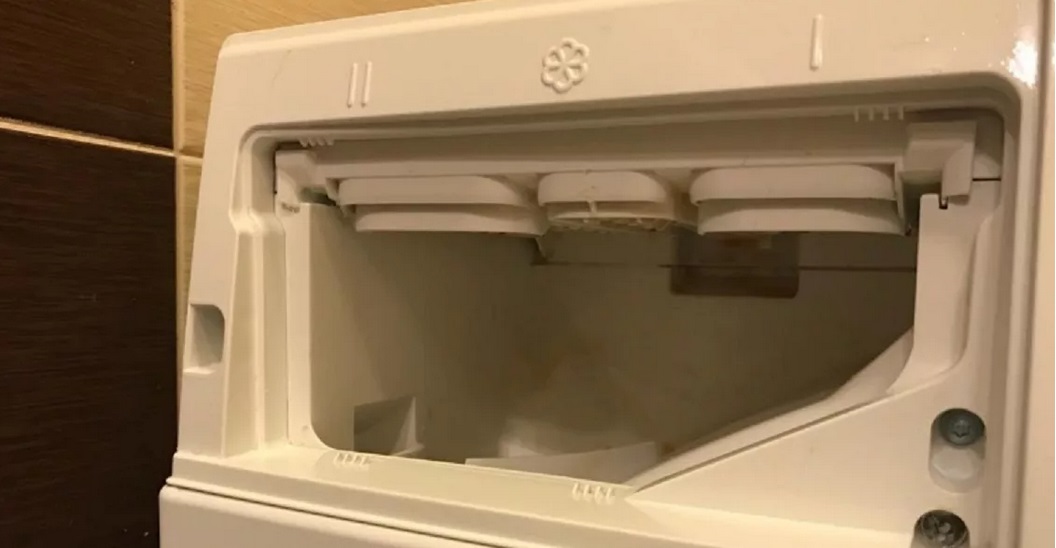

- remove the powder receptacle from the machine;

- Unscrew the screws securing the dashboard;

- disconnect the control panel and place it on the lid of the washing machine without touching the wiring;

- open the loading hatch door;

- Using a slotted screwdriver, pry the outer clamp securing the drum cuff and pull the ring out;

- insert the sealing collar into the drum;

- Unscrew the screws holding the front wall of the case, remove the panel and put it aside;

- unhook the wiring from the heating element;

- press the central screw of the heater inward;

- gently rocking, remove the heating element from the machine body;

- remove foreign objects from the tank through the resulting hole.

If your SMA model has a heating element located at the back, then the work will be even easier - you won’t have to remove the control panel and the front wall. If you are repairing a washing machine for the first time, it is better to take photographs of all stages of dismantling so as not to make mistakes during reassembly.

Drive element

For Bosch washing machines with a commutator motor, drum rotation is ensured by a drive belt. The rubber band is pulled onto the pulley of the motor and centrifuge. When the strap comes off, unwinding the container becomes impossible. If you have a model with an inverter and direct drive, then this reason can be immediately ruled out.

It's easy to check if the drive belt is in place.Remove the back wall of the SMA housing and inspect the drum pulley. The loose rubber band will lie under the machine.

Belts don't just come off like that. They either tear or stretch. In any case, it is better to buy and tighten a new rubber band. The components are inexpensive, and the work is easy to do yourself.

Engine speed sensor

Another possible reason is a malfunctioning tachometer. The control unit, receiving incorrect information about the intensity of rotation of the electric motor, blocks the cycle, displaying an error E21. To test the tachogenerator:

- de-energize the SMA;

- After removing the bolts, dismantle the top and back walls of the machine body;

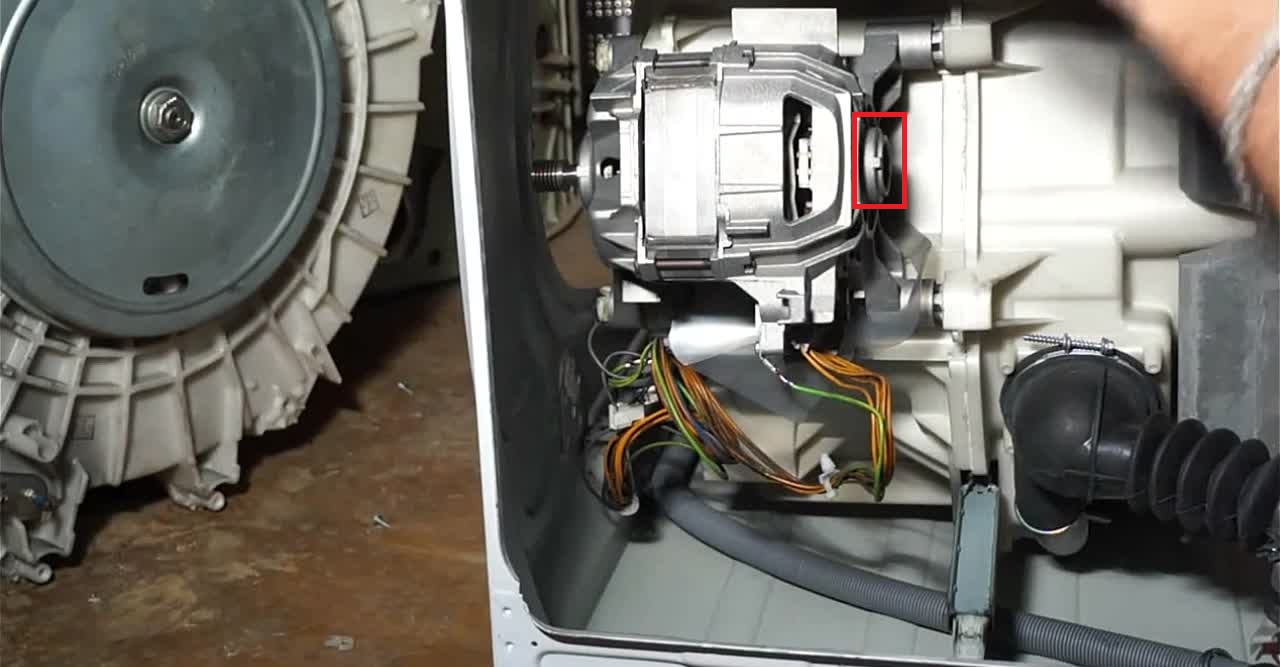

- find the motor - it is located at the bottom of the washer;

- look for a small metal ring on the motor, this is the tachometer;

- disconnect the wires connected to the tachogenerator;

- Having moved the multimeter to measure resistance, attach the tester probes to the terminals of the Hall sensor.

A working tachometer produces a resistance of about 60 ohms.

A broken tachogenerator cannot be repaired. A new Hall sensor is purchased for a specific model of Bosch washing machine. Installing it is quite simple:

- use a thin screwdriver to pry up the top cover of the old sensor and remove it;

- remove the fixing bolts;

- dismantle the failed tachogenerator;

- install a new Hall sensor in its place;

- connect the wiring, connecting the tachometer to the motor;

- assemble the SMA body.

Sometimes it is possible to eliminate the error by tightening the tachogenerator fastenings. Often it is poor committing that causes code to be rendered.

Electric motor

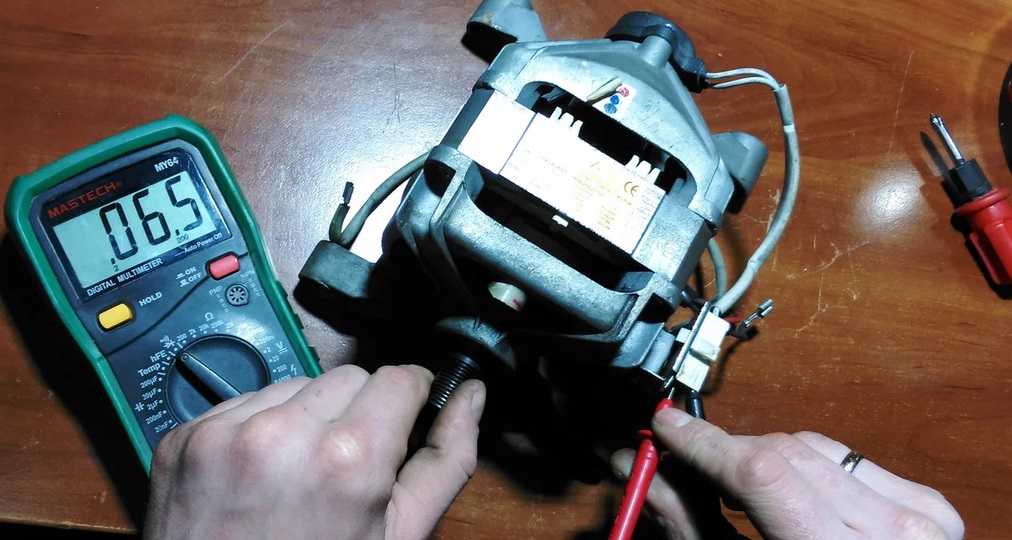

If the drum turns easily by hand, but after starting the cycle it stands still, the “culprit” of the error is probably the engine.To check the electric motor:

- remove the superior and posterior wall of the MCA;

- tighten the drive belt;

- disconnect the wires connected to the engine;

- Unscrew the fasteners and remove the motor from the washing machine body.

Hold the motor in your hands and check its windings. A multimeter will be useful for this. The tester probes are connected to the lamellas of the electric motor. The resistance discrepancy rate is up to 5 ohms.

Additionally, you need to check the electric motor housing for breakdown. One multimeter probe is applied to the surface of the engine, the other - alternately to the winding lamellas. The device should give a maximum resistance value, this will mean that there is no current leakage.

Carbon brushes installed in commutator motors are prone to natural wear. When they wear out, the engine starts to work incorrectly. Every 3-4 years, graphite rods have to be replaced.

Replacing electric brushes is quite simple:

- remove the wire from the brush contact;

- remove the graphite rods from the motor housing;

- clean the engine with an abrasive sponge, then wipe it with a soft cloth;

- install new electric brushes and connect the wires to them.

Electric brushes are always replaced in pairs, even if only one element is worn out.

After testing the winding and replacing the electric brushes, put the motor back in place. Then assemble the machine body, connect it to the network and run the test cycle. If the drum begins to rotate and the error goes away, the repair can be considered completed.

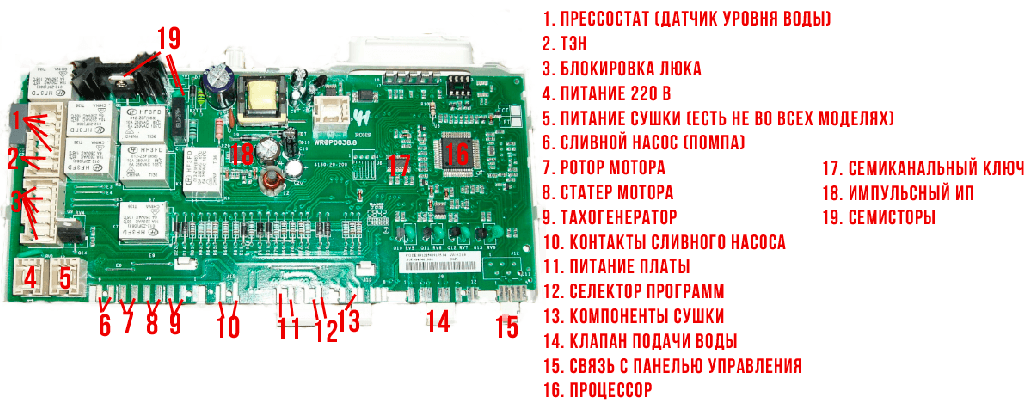

Let's inspect the electronic board

If the control module suddenly breaks down, any errors may be displayed on the machine’s display, including E21. The board fails due to sudden power surges in the network, moisture that gets inside the washing machine, and other things.It will not be possible to diagnose an electronic unit without certain knowledge. At home, you can only perform a visual inspection.

The sequence of actions will be as follows:

- turn off the power to the washing machine;

- remove the cover of the washing machine;

- remove the powder receptacle;

- disconnect the device by unscrewing the screws securing it;

- carefully inspect the electronic module.

Stains, rust, blisters, faded coating, darkened tracks are clear signs that the unit requires repair. It is better to entrust diagnostics of the control module to service center specialists. This is a complex job that requires certain knowledge and skills.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment