Error E10 in Zanussi washing machine

Error E10 may appear on the machine’s display at any stage of the wash. The system, having diagnosed a problem, immediately blocks the operation of the Zanussi washing machine. What this fault code indicates and how to return the machine to working order, we will tell you further.

Error E10 may appear on the machine’s display at any stage of the wash. The system, having diagnosed a problem, immediately blocks the operation of the Zanussi washing machine. What this fault code indicates and how to return the machine to working order, we will tell you further.

What caused this code?

The decoding of the codes presented in the equipment instructions will help you understand the causes of the malfunction. The manufacturer interprets the error E10 as “no or insufficient water in the tank.” Without the rated amount of liquid, the system cannot start or continue washing. Various sensors note the discrepancy between the volume of water in the tank and the standard level. Error E10 in Zanussi washing machines can be caused by:

- lack of water in house utility networks;

- failure of the inlet hose;

- clogging of input filters;

- breakdown of the fill valve;

- malfunction in the electronics of the SMA;

- self-draining of water from the system.

Self-draining means spontaneous leakage of liquid from the tank.

Although different types of fault codes are programmed into the intelligence memory, which can indicate a specific problem, some models of Zanussi washing machines make do with the general E10 coding. To eliminate the damage and repair the washing machine, you will have to eliminate the possible causes of malfunctions one by one.

You can carry out the repair yourself, since in most cases it is quite simple to remove the error. However, if the problem is deeper - for example, the electronics have failed or a leak has occurred due to a crack in the tank, then it is better to contact a service center.

We remove the code ourselves

What to do first? It is necessary to proceed from the main reasons, as a result of which the water in the tank may not be enough for washing. If the Zanussi washing machine displays a code a couple of minutes after starting the program, most likely there is no water in the house. Perhaps, due to some circumstances, management services simply turned off the water supply. Also, error E10 may appear when the pressure in the water supply system is low. This factor can be eliminated by opening the cold water tap and making sure that the stream flows under sufficient pressure.

You should then inspect the inlet hose for cracks. If the surface of the tube is intact, unscrew it from the washer and make sure there are no blockages inside. Often, a filter element is installed at the inlet of the inlet hose, which does not allow various impurities contained in the water to enter the system. Over time, the filter becomes clogged and can no longer provide normal throughput. The E10 code can be resolved by cleaning the filter element or replacing it with a new one.

You should then inspect the inlet hose for cracks. If the surface of the tube is intact, unscrew it from the washer and make sure there are no blockages inside. Often, a filter element is installed at the inlet of the inlet hose, which does not allow various impurities contained in the water to enter the system. Over time, the filter becomes clogged and can no longer provide normal throughput. The E10 code can be resolved by cleaning the filter element or replacing it with a new one.

At the point where the inlet hose is connected to the water pipe, a special shut-off valve is installed. Check that it is open and does not block the flow of water.

Failure to remove waste water from the tank can also cause error E10 to appear on the display. It is very simple to check whether the drain is performed correctly - just disconnect the drain hose from the sewer pipe and lower the end into the bathtub, sink or toilet. This will help you see if fluid is being removed from the system or if something is slowing down its drainage.

Check that the drain hose is positioned correctly; the middle part of the hose should extend 55-60 cm from the floor level, forming an “elbow”.

If the error cannot be eliminated by performing the manipulations, the intake valve or pressure switch has probably broken down. Carrying out repairs with your own hands in this case will be quite difficult. To diagnose and correct damage, it is better to invite an experienced SMA service technician who will quickly deal with the problem.

Let's check and replace the fill valve

A fault code may be displayed on the digital screen due to the failure of the element responsible for drawing water from the centralized supply system. If the fill valve breaks down, the automatic machine will simply stop filling the tank with water and display an error message E10. The algorithm for diagnosing the valve will be as follows:

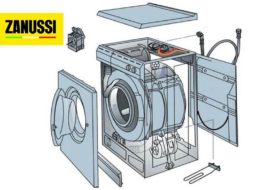

- remove the top cover of the Zanussi washing machine;

- remove the inlet valve from the washing machine, attach the inlet hose to it, open the valve that shuts off the water supply. During such manipulation, there should be no valve leakage;

- Apply a voltage of 220 Volts separately to each section of the element. The section of the valve where the current flows will be triggered. So, water should be supplied from the corresponding tube.

If any of the filler valve coils do not operate when tested, therefore, the element must be replaced.

A multimeter will help you check the fill valve. The tester probes are applied to the coils to measure the resistance in them. If the device displays a value in the region of 2-4 kOhm, then the coil is fully operational.

A multimeter will help you check the fill valve. The tester probes are applied to the coils to measure the resistance in them. If the device displays a value in the region of 2-4 kOhm, then the coil is fully operational.

In theory, the fill valve cannot be repaired. Experts, if they detect a breakdown, recommend not to repair, but to completely replace the part. Moreover, the spare part is relatively inexpensive.But if the desire to save money is stronger, and you have a similar valve from another washing machine in stock, you can try to replace the faulty coil by removing it from another element. Be prepared that your efforts may not pay off, you will not be able to fix the valve, and, ultimately, you will still have to go to the store.

So, after purchasing a new fill valve for a Zanussi washing machine, you need to install it in place of the faulty one and make all the connections. The algorithm of actions when replacing an element will be as follows:

- turn off the power to the equipment by unplugging the power cord from the outlet;

- remove the top cover of the case by unscrewing the fastening bolts;

- Disconnect the supply wiring and hoses from the inlet valve. Basically, the tubes are attached to the sensor with clamps, which can be reused. Sometimes fastening clamps are designed for one-time use; here you will have to take care of purchasing new clamps in advance;

Carefully remember the wiring and hose connection diagram, or better yet, take a picture.

- remove the valve from the MCA body. Depending on the mounting method, simply unscrew the bolts holding it or bend the latches;

- install the new fill valve in place, fix it in the body;

- Based on the photo, connect the wires and hoses.

Afterwards all that remains is to put the top cover of the machine body back in place. Now you can test your Zanussi washing machine for performance. Plug in the appliance and start the washing program. If the problem really is that the fill valve is broken, error E10 should reset.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment