Error E04 in Hansa washing machine

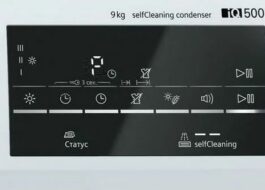

Modern Hansa washing machines are able to independently detect breakdowns that have occurred in the system and notify the user about them. So, the equipment displays the corresponding fault code. If you notice error E04 on the screen, you should start diagnosing the machine as soon as possible. Let's figure out which nodes will have to be checked.

Modern Hansa washing machines are able to independently detect breakdowns that have occurred in the system and notify the user about them. So, the equipment displays the corresponding fault code. If you notice error E04 on the screen, you should start diagnosing the machine as soon as possible. Let's figure out which nodes will have to be checked.

What is this code?

Typically, the Hans automatic washing machine displays error E04 either at the very beginning of the cycle or in the middle of the wash, before rinsing. For an attentive user, it will not be difficult to associate this fault code with the process of drawing water into the tank. But what kind of element are we talking about failure?

The intelligence of the Hansa washing machine is programmed to determine how much liquid should be drawn into the drum at each stage of the cycle. The pressure switch controls the fullness of the container. Error E04 is displayed on the display if the machine for any reason takes too much water into the tank. When the machine displays error E04, you can suspect a breakdown of one of three elements:

- water level sensor. It is the pressure switch that controls the amount of water in the tank and sends a signal to the “brain” when the set should stop;

- intake valve. The membrane opens when it is necessary to pour water inside, and closes when the tank is full;

- control module. The “brain” coordinates the process of collecting water, activates the filling valve, closes it, and receives signals from the pressure switch.

The reason for error E04 will be either a faulty inlet valve, a broken level sensor, or a failed control module.

What to do first? First you should try to reset the error. Sometimes it may not indicate a breakdown at all, but be the result of a simple short-term failure. Therefore, unplug your Hansa washing machine, wait 20 minutes and start the appliance again. If the procedure does not produce results, you will have to check each of the three modules responsible for drawing water into the system. Having discovered a breakdown, you need to fix it. The repair progress will depend on the cause of the fault code.

The pressure switch is "jamming"

If you do not have time to look for the cause of the breakdown of the Hansa washing machine, it is better to immediately call the service center and entrust the repair to a specialist. If you want to fix the problem yourself, you should start diagnosing the machine. You should check the automatic machine from simple to more complex. Therefore, the first in line will be the pressure switch.

The water level sensor in modern washing machines breaks down more often than any other parts. Usually the element tube becomes clogged and it stops functioning correctly. Sometimes the pressure switch coil burns out or its wiring breaks. To check the level sensor:

- turn off the power to the automatic machine. Close the valve responsible for the water supply;

- Unscrew the bolts holding the “cover” of the case, remove the top panel and put it aside;

- find the pressure switch. It is located closer to the front right corner of the washer;

- unscrew the bolt that secures the sensor to the housing;

- disconnect the wiring and pressure switch tube;

- use a multimeter to “ring” the level sensor coil;

- Use a tester to check each pressure switch wiring for breakdown.

If the check shows that the liquid level sensor is working, try blowing out its tube.You can also remove blockages from the hose that fits onto the pressure switch fitting.

Dust or cobwebs caught in the level sensor tube may cause it to not work correctly.

After cleaning the pressure switch, secure the element in the housing and connect the wiring and tube to it. Next, it is checked whether it was possible to correct the situation and return the machine to working capacity.

Testing and changing the intake valve

If the problem is not with the pressure switch, you will have to pay attention to the solenoid valve. It is located on the back panel of the Hansa washing machine, near the inlet hose connection. It will not be difficult to detect the element. You can check the intake valve with a multimeter. The tester probes are applied to the coil and sensor contacts. If a malfunction is detected, you will have to replace the entire part; the solenoid valve cannot be repaired.

If there are no electrical problems, you need to check the flow filter. The mesh is located here, in the place where it is connected inlet hose. The filter element often becomes clogged with impurities and becomes covered with limescale. After cleaning the part, you should return it to its place and check whether the washing machine is working.

Is it worth going to the control board?

If the pressure switch and inlet valve of the Hansa washing machine are fully operational, the flow filter is cleaned, but the machine still issues E04, you will have to check the electronic unit. It is not worthwhile to independently diagnose the control module without having the necessary knowledge - this can only harm the equipment.

In order not to aggravate the situation, it is better to entrust the inspection and repair of the main unit to a specialist with extensive experience working with electronics. The technician, using special equipment, will test the firmware, reset it, and reinstall it if necessary.It may be necessary to replace some semiconductor elements on the board and solder the tracks.

In some “neglected” cases, only replacing the control unit will help eliminate the problem. Here you need to compare the cost of the module and the new machine, and decide on the feasibility of repairs. So, when you see fault code E04 on the machine’s display, it is better to immediately begin diagnosing the equipment. The range of breakdowns is not so wide, so identifying the cause of the problem will not be difficult.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment