Error D02 in a Bosch washing machine

The self-diagnosis system of faults, which is equipped with modern Bosch automatic machines, immediately notifies the user of a malfunction in the operation of the equipment. After interpreting the fault code displayed on the display, you can understand why the machine does not want to work. If you find error D02 in your Bosch washing machine, don’t be upset. In most cases, you can return the washing machine to working capacity yourself, after simple repairs.

The self-diagnosis system of faults, which is equipped with modern Bosch automatic machines, immediately notifies the user of a malfunction in the operation of the equipment. After interpreting the fault code displayed on the display, you can understand why the machine does not want to work. If you find error D02 in your Bosch washing machine, don’t be upset. In most cases, you can return the washing machine to working capacity yourself, after simple repairs.

Transcription required

The first step is to understand what this designation means. How the manufacturer interprets the error can be found in the user manual. Code D02 informs that waste water was not removed from the tank within the time allotted for draining. You will have to look for what exactly is broken with your own hands. The diagnosis should begin by checking the following elements of the SMA:

- garbage filter. The part is inspected for blockages. If the filter element becomes clogged, the rate of water removal from the tank is greatly reduced;

- pump impellers. The part could be blocked - in this case, debris is wrapped around the impeller blades or a foreign object gets stuck between them. Its rotation becomes impossible. It is also likely that the plastic simply broke;

- drain sleeve. If the drain hose is kinked or incorrectly connected, water may remain in the system rather than go down the drain;

- sewer pipe. Perhaps it is the home communications that are clogged, and as a result, the liquid cannot be drained from the SMA tank. Usually, in this case, draining from the bathtub and sink will be difficult;

- drain pump.The element is probably out of order and cannot fully pump out water.

To find the exact cause of error D02, you will have to carefully check each described element of the Bosch washing machine. First, you should inspect the simplest parts - the garbage filter, the impeller and the drain hose. Only after this should you begin to disassemble the machine and test the pump.

Inspecting the filter element

In some cases, cleaning the drain filter helps correct the current situation. It is a plastic spiral to which dirt that gets into the machine sticks. The filter element is located in the lower right corner of the automatic machine behind a small hatch or narrow false panel. To inspect and wash the element you must:

- de-energize the SMA;

- disconnect the equipment from the water supply;

- open the hatch or false panel by releasing the fastening latches;

- Place dry rags under the washing machine or place a bowl to collect water;

- remove the element from the housing by turning the cover from left to right.

Do not remove the filter immediately after the wash cycle is completed; the water in the system will not have time to cool down, and there will be a high chance of getting burned.

It is necessary to remove all debris from the pulled out plastic spiral and clean it from plaque. Then rinse under running warm water. If it is heavily soiled, it is recommended to pre-soak the filter for half an hour in water with the addition of citric acid.

The hole that opens after removing the debris filter will allow you to inspect the impeller. Shine a flashlight inside the machine. If you find wound hair or other debris on the impeller, be sure to clean the part. Insert a screwdriver or other long thin object into the hole and watch how the impeller rotates.Ideally, there should be a slight strain in its rotation.

Let's check the drain hose

Then you should pay attention to the drain hose, through which the waste liquid goes into the sewer. Inspect the hose; it is probably simply bent in some area. If visual diagnostics do not reveal any problems, you should seal off the hose from the sewer pipe and see if there are any blockages in its cavity.

A correctly connected drain hose to the SMA will have a bend designed to prevent a siphon effect.

If an attached hose is connected to your washing machine, the drain pump of the Bosch machine experiences a greater load. The optimal length of the hose from the pump to the outlet into the sewer network is from one and a half to three meters. If the drain hose is longer, the likelihood of premature failure of the drain pump increases significantly.

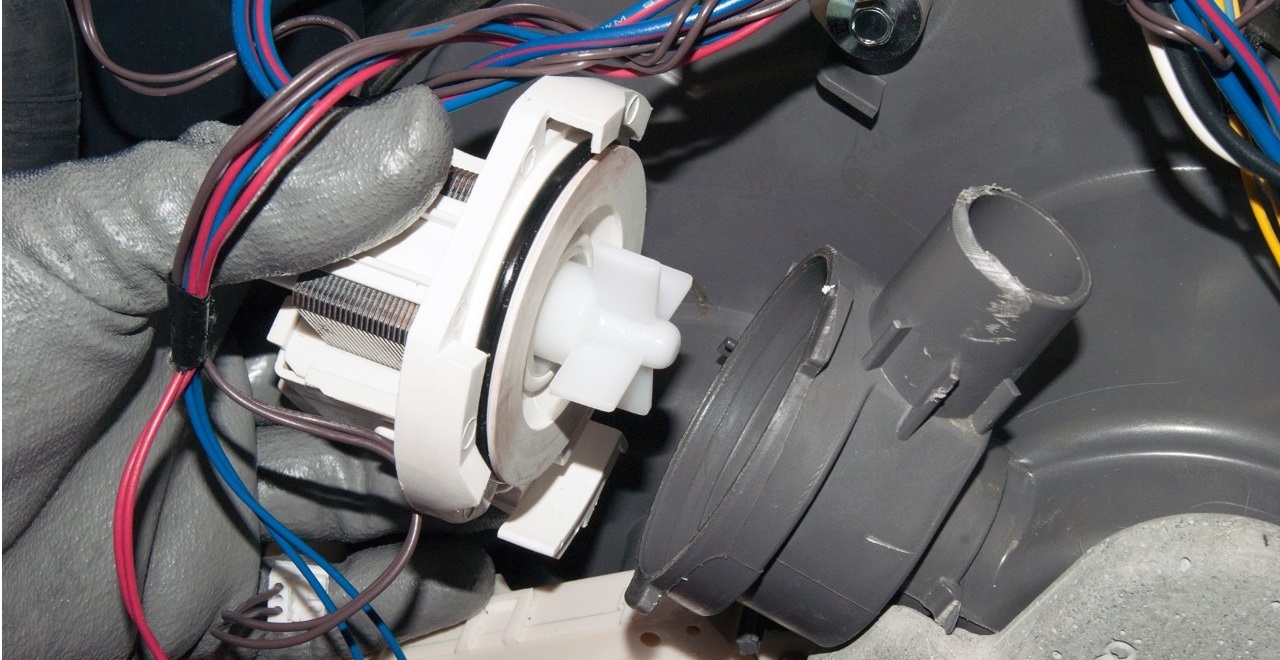

We check the pump in detail

If you still cannot find the reason for the display of code D02 on the display, you will have to move on to checking the pump. To gain access to the drain pump, you need to place the washing machine on the back wall. Before turning the unit over, make sure there is no water in the dispenser and tank. Algorithm of actions for diagnosing a pump using the first method:

- disconnect the SMA from the network and communications;

- Place the washer on the floor and look inside through the missing bottom;

- remove the chips or terminals from the pump;

- connect to the drain pump the terminals from the conductor with a plug, which must be prepared in advance;

- make sure that the connection is secure and there are no third-party contacts;

- plug the conductor into the socket;

- evaluate the performance of the pump. If it starts to function and remove water, then everything is in order with the drainage system.The reason for the impossibility of removing water from the tank will have to be sought in the main control module or pressure switch.

The second way is to test the pump using a multimeter. The tester is switched to resistance measurement mode, and its probes are applied to the pump contacts. If the multimeter gives a resistance value in the range from 150 to 260 Ohms, then the drain pump is working. The display of the device “0” will notify you of a short circuit of the element. If the standard value is exceeded, then we can talk about a break in the stator winding.

Having identified deviations in the resistance value and diagnosed a breakdown, it is necessary to dismantle the failed pump and install a new pump. Repairing an old element with your own hands is impractical and sometimes simply impossible. A mechanical check of the drain pump is also allowed. To diagnose the pump in this way, you must:

- remove the snail;

- turn the impeller. Ideal if the rotation is intermittent;

- shake the impeller left and right across the axis. If you notice even a slight play, then you can talk about a pump malfunction and the need to replace it;

- Plug the pump into a power outlet by connecting the power cord to it. The motor should work properly without making noise.

The replacement drain pump is selected by serial number; ideally, buy original components, but it is also possible to install an analogue with similar characteristics.

It is important that the pump you purchase is of similar power and has the same type of attachment to the landing site. If the fault cannot be eliminated after checking, the cause probably lies in the main control unit. It is better to entrust board repair to an experienced technician.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment