Error 5 in Haier washing machine

For a Haier washing machine to display the error “ERR5” or just “5”, it is enough to forget to open the water supply tap. The washing machine reacts in the same way to a temporary shutdown of water throughout the house. Therefore, most housewives do not worry about the warning on the display and do not start diagnostics. But sometimes the “five” speaks of problems that will not disappear without inspection and repair. What problems are we talking about and how to deal with them?

For a Haier washing machine to display the error “ERR5” or just “5”, it is enough to forget to open the water supply tap. The washing machine reacts in the same way to a temporary shutdown of water throughout the house. Therefore, most housewives do not worry about the warning on the display and do not start diagnostics. But sometimes the “five” speaks of problems that will not disappear without inspection and repair. What problems are we talking about and how to deal with them?

In-line filter clogged

Most often, error 5 indicates a clogged flow filter. This is a round plastic mesh that is installed directly between the filler valve of the machine and the inlet hose. By filtering tap water, the mesh takes the entire “blow” on itself, so scale, small debris and other particles and inclusions in the pipes settle in small holes. Once dirt clogs most of the part, the washer cannot begin to pick up. The situation can only be corrected by cleaning the plastic.

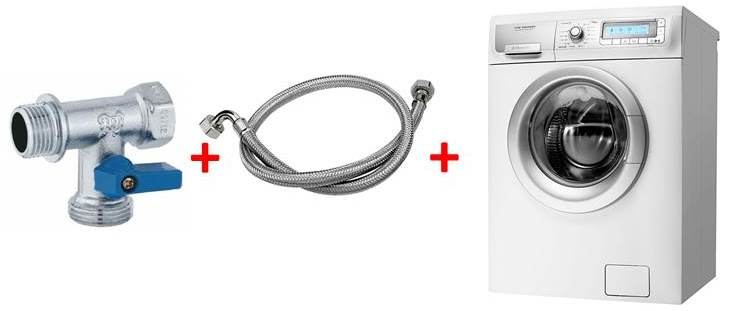

Error “5” on Hyer washing machines indicates problems with water getting into the tank.

Anyone can cope with the task, since there is no need to disassemble the machine, repair complex mechanisms, or even get user instructions. It is enough to prepare the pliers and not deviate from the simple scheme of actions.

- Turn off the machine from the power supply and turn off the water supply tap.

- Disconnect the inlet hose from the machine body by hand or using pliers. Be prepared for the fact that there is always water left in the rubber band, which is better to pour into a suitable container or sink than on the floor.

- Having opened access to the filter, hold the plastic piece with pliers and gently pull it towards you.Much effort is not required - the mesh can be easily removed from its seat.

- Rinse the removed mesh under a strong stream of water. For comprehensive cleaning, soak the filter for 30-50 minutes in a solution of citric acid in the proportion of 1 teaspoon of powder per glass of liquid. Boiling water cannot be used, as at high temperatures the plastic is easily deformed and deteriorated. In order not to buy a new part, you need to use only warm water. Cold is undesirable, since “lemon” does not dissolve well in it.

- Using pliers, return the mesh to its place until it stops.

- Screw on the inlet hose and open the water supply tap.

- Make sure that there is no water leaking at the joint.

At the finish line, we make sure to check whether the problem has been resolved. To do this, connect the washing machine to the mains and start any mode. If the error is not displayed and water begins to flow into the drum, then the work was successful.

Let's check the filling valve

Among the causes of error “ERR5” is a faulty solenoid filling valve. It is located under the top cover of the machine and is responsible for the flow of water into the machine. If its operation is disrupted, the unit does not perceive the system command to start the cycle, and washing does not begin. To correct the situation, you need to take out the “box” and check it for integrity and functionality.

Finding the valve is not difficult. It is enough to remove the housing cover and see a black or white plastic “box” near the back wall near the inlet hose on one side and the pipes leading to the dispensary on the other. Then we proceed like this:

To avoid errors during reassembly, it is recommended to photograph all connectors and connections with a camera.

- We inspect the valve body for damage, chips, and traces of burning. If no visual problems are found, we listen to it;

- disconnect the connected pipes by loosening the metal clamps with pliers;

- release the connected wiring;

- Unscrew the bolts holding the part and remove the valve.

Now you need to verify that the breakdown has occurred. The easiest way to diagnose is to lift the device under the sink or basin, connect the inlet hose and open the water supply tap. A working element should hold back the flow. If a leak is noticeable, the valve will have to be replaced with a new one. There are other ways to diagnose the valve.

Now you need to verify that the breakdown has occurred. The easiest way to diagnose is to lift the device under the sink or basin, connect the inlet hose and open the water supply tap. A working element should hold back the flow. If a leak is noticeable, the valve will have to be replaced with a new one. There are other ways to diagnose the valve.

- Apply 220 volts to the valve coil. If in this case the device works and lets water through, then everything is in order. But be careful and careful, as water and electricity should not come into contact.

- Connect the device to the multimeter. We turn on the “Resistance” mode on the tester and alternately attach the probes to the windings, evaluating the indicators. If the display shows values of 3 kOhm, then the part is fully operational.

Repairing a faulty valve yourself will not help. The part is not repairable, so you will have to replace the old “box” with a new one. To do this, we purchase a suitable copy from a specialized store and install it according to the previously described scheme, but in reverse order. We fix the valve with a retaining bolt, connect the wiring to the connectors, return the pipes and secure everything with clamps. Lastly, install the top cover of the washer and run a test wash.

Inspecting the wiring

If everything is in order with the flow filter and water supply valve, then we next check the internal wiring. It is rare, but it happens that the wires to the control board, pressure switch and existing system break, and the machine loses the “connection” between the elements. As a rule, washing machines in private homes where wild rodents live are at risk.

If you are unable to find the cause of the error yourself, you must call a specialist from the service department.

The instructions on what to do to check are simple. It is enough to remove the top cover of the washing machine and visually assess the condition of each wire. First of all, we look at the integrity of the insulation, and finally we check the quality of the contact connections. At the same time, it is recommended to clean the pressure switch tube.

Fault code “5” on Hayer washing machines indicates problems with water intake. Therefore, we first check the hoses, valves, filters and wiring.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment