Breakdowns of Ardo top-loading washing machines

Washing machines of different brands have both their advantages and disadvantages. This must be taken into account when choosing a “home assistant”. Knowing the “weak points” of a particular washing machine, you can avoid some breakdowns and extend its service life.

Washing machines of different brands have both their advantages and disadvantages. This must be taken into account when choosing a “home assistant”. Knowing the “weak points” of a particular washing machine, you can avoid some breakdowns and extend its service life.

Let's look at typical problems with Ardo top-loading washing machines. Let's tell you what problems users encounter most often. We'll explain how to fix the problem at home.

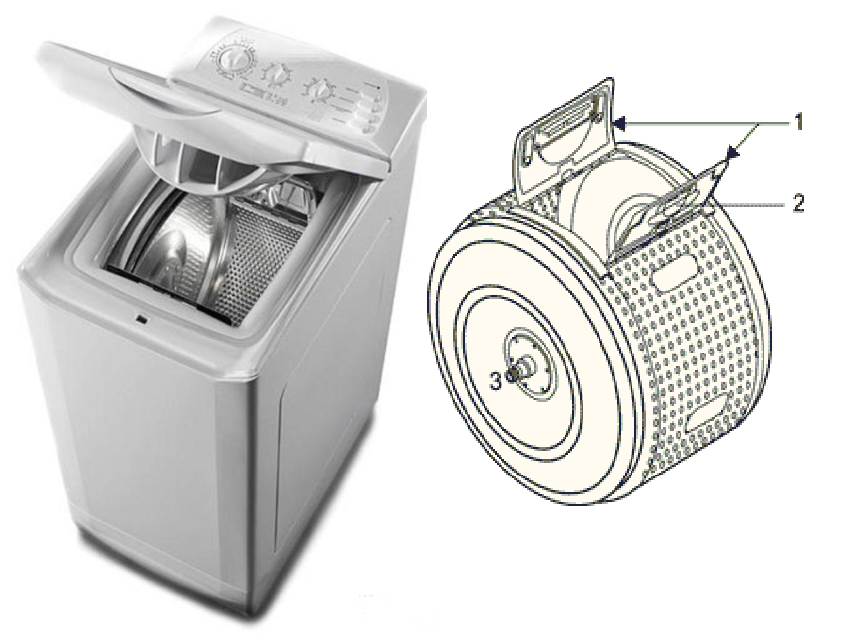

Broken latch causes drum to jam

Every third owner of an Ardo vertical system contacts the service center with a similar problem. Tub spinning is the most common problem with top-loading washing machines. The user lifts the lid, opens the doors, and sees not the drum opening, but a metal wall.

Most often, the tank rotates due to a malfunction of the locking mechanism or loose closure of the valves.

Returning the drum to its normal position is not easy, but it is possible. Therefore, there is no need to immediately call the service center. You will have to pay a lot to call a specialist. To rotate the tank, you must:

- take a long metal wire with a diameter of 3-6 mm;

- bend one end of the wire to make a hook;

- lower the wire with the catching end down;

- hook the flap and attempt to close the drum flaps;

- After closing the doors, turn the drum until the hatch is in the desired position.

The main difficulty is that you have to act blindly. If your Ardo model has a hole that is too small and you can't get the wire down, try widening the "entrance" and try again.

If you can’t spin the drum with wire, there is another, more complicated method. You will have to disassemble the “vertical”, get to the doors from the side or below, close them and return the tank to the desired position. However, in most cases, users are still able to fix the situation with a “hook”.

Weak control module

Often, owners of Ardo vertical washing machines are faced with an extremely unpleasant problem - a breakdown of the control module. The machines either freeze in the middle of the cycle or suddenly interrupt the running washing program. Sometimes SMAs “delight” users by sticking buttons on the control panel - in this case, one or two modes may not turn on, while the “tidy” responds to other commands without problems.

It is better to entrust diagnostics and repair of the control board to service center specialists.

Repairing the main control unit is quite difficult. It will not be possible to cope with such a task without having experience working with electronics. Therefore, in order not to aggravate the situation, it is better to turn to professionals.

Typically, repairs involve reflashing the board or replacing semiconductor elements. It is also possible that there is oxidation of the contacts or problems with the terminals. In any case, diagnostics of the unit will be required.

Owners of washing machines can protect equipment from breakdowns of this kind. The electronics of Ardo automatic machines are sensitive to power surges in the network, so it is better to install a stabilizer that will take over all current surges. This is exactly the case when it is easier to prevent a problem than to solve it later.

Let's pay attention to the bearings

Another typical malfunction is bearing failure.The seal that protects the rings from moisture dries out, so water begins to seep inside. As a result, the lubricant is washed out, the unit is destroyed, the tank becomes loose, and the machine begins to knock and rattle during operation.

The main sign of broken bearings is a rumble and knocking sound when the machine is running, which intensifies during the spin stage. It’s easy to check your guess in this case. Open the drum and spin it by hand. If there is noticeable play in the container and it creaks when rotating, then it’s time to change the bearings.

To repair the unit, you will have to completely disassemble the washing machine and remove the tank from it. First, the top cover of the SMA housing is removed, then all the main parts are disconnected from the plastic container: motor, pump, gearbox, starting capacitor. When nothing interferes with the recess, the element is removed from the machine.

The next stage of repair is dividing the tank in half. For Ardo washing machines it is non-separable, so you will have to be smart. Craftsmen saw the plastic container with a hacksaw - this is necessary to get to the bearings.

Having halved the tank, you need to remove the oil seal and knock out the damaged metal rings. If the bearings are stuck, pre-treat them with WD-40. Afterwards the elements are changed along with the oil seal.

Next, you will need to connect the halves of the tank. Usually craftsmen “sit” them on sealant, additionally soldering the parts and securing them with self-tapping screws. Afterwards the washer is assembled in the reverse order. Then the test cycle starts. Carefully monitor the operation of the machine, as you need to make sure that the container does not leak.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment