Malfunctions and repairs of AEG washing machines

AEG washing machines are known all over the world as high quality machines made in Germany. Despite the fact that today they are produced under the control of Electrolux, their quality remains the same. However, such machines can break down, individual units can simply wear out over time. In this case, repair of AEG washing machines is required, in most cases it can be done independently. How to find the cause of the malfunction, how to eliminate it, and is it worth doing? We will answer these questions.

AEG washing machines are known all over the world as high quality machines made in Germany. Despite the fact that today they are produced under the control of Electrolux, their quality remains the same. However, such machines can break down, individual units can simply wear out over time. In this case, repair of AEG washing machines is required, in most cases it can be done independently. How to find the cause of the malfunction, how to eliminate it, and is it worth doing? We will answer these questions.

Symptoms of malfunctions and their causes

Breakdowns in AEG washing machines are extremely rare, and even these rare breakdowns are most often the result of improper installation or improper operation. In addition, one should not exclude the percentage of defects in production, force majeure situations when a power surge occurs in the network, as a result of which the control board or heating element burns out.

Important! If you are vigilant and always unplug your washing machine, you can reduce the risk of exposure to power surges.

The most common symptoms that appear in AEG automatic washing machines are the following:

- The washing water does not heat up to the set temperature, the washing does not start or takes place in cold water;

- when turned off, a grinding and knocking sound is heard in the drum when it is rotated by hand;

- water does not fill into the drum;

- The water does not drain from the machine, the washing process stops.

With such breakdowns, the most common cause is a malfunction:

- heating element;

- temperature sensor;

- control module;

- drain pump.

How to diagnose a breakdown

Once you realize that the machine has stopped working normally, you can try to determine the problem yourself. Firstly, if the AEG machine has a display, then an error code should appear on it indicating a specific breakdown. The decoding of such codes is in the instructions for the machine. Let's offer some of them.

- E11 (C1) - an error informing that there is no water supply to the tank, most likely in this case the reason is a faulty fill valve;

- E21 (C3 or C4) – waste water does not drain for a long time, the probable cause is a breakdown of the pump, the electronic controller may be faulty;

- E61 (C7) – water does not heat up to the required temperature for a long time, in this case there is a breakdown in the heating element; For your information! This error only appears in diagnostic mode.

- E71 (C8) – the resistance of the temperature sensor does not meet the specified limits, this indicates a breakdown of the sensor itself or the heating element, which happens less frequently;

- E74 – the position of the temperature sensor is out of order;

- EC1 – blocking of the fill valve; in this case, both the valve itself and the control board of the washing machine may be faulty;

- CF (T90) – failure in the control board.

There are quite a lot of error codes that the manufacturer has embedded in the microprocessor. We have suggested only those that arise most often. In some cases, such codes may not occur, then it is necessary to run the diagnostic mode. To do this you need:

- Turn the programmer to the off position (AUS), thereby canceling the selected program, and turn off the machine.

- Hold down the Start (Pause) key and the Exit key simultaneously.

- Turn on the machine and turn the programmer clockwise one notch.

- Hold down the Start (Pause) key and the Exit key simultaneously until the diagnostic mode appears, or rather an error appears on the display.

To exit test mode, you need to turn off the machine, then turn it on and turn it off again.

Trouble-shooting

What to do if you find one of the above faults? There are two solutions: try to fix it yourself or call a specialist. If the heating element fails, it is quite possible to solve the problem yourself. The action plan in this case is as follows:

- We purchase an original heating element for the AEG washing machine in accordance with the model of the machine.

- We inspect the rear cover of the body; if it has a small technological hatch, then most likely the heating element is located behind the front cover of the machine body. If there is no such hatch, then the heating element is located behind the rear panel.

When in doubt, start disassembling from the back of the case as it is much easier to remove. - Having opened access to the heating element, we check its resistance using a multimeter, which should be 30 ohms for a working unit.

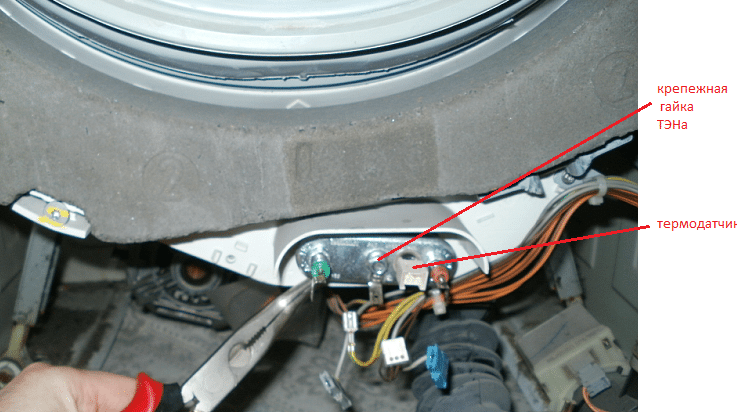

- If the heating element is faulty, unscrew the bolt in the center and disconnect the sensors and contacts from the heating element.

- Using gentle movements left and right and towards yourself, we remove the heating element from the holder.

- We insert the new heating element into the holder and tighten the retaining bolt.

- We connect sensors and contacts.

The temperature sensor is also easy to change. On modern washing machines, a thermistor is installed as a temperature sensor, which is fixed to the heating element. Therefore, when checking the heating element for performance, you can immediately check the thermistor too.

If the drain pump breaks down, you can also carry out independent repairs.However, this is somewhat more difficult than replacing the heating element, since it can be reached through the front wall of the machine. Instructions for replacing the pump can be presented as follows:

- Remove the top housing cover.

- Remove the front panel, behind which there is a drain filter. At the same time, drain the remaining water and unscrew the bolts holding the pump.

- We take out the powder cuvette and unscrew the bolts that hold the control panel.

- Carefully lift the panel up so as not to damage the wires connecting the panel to sensors and other units.

- Remove the clamp on the drum cuff, and then the cuff itself from the front wall.

- We unscrew all the bolts that hold the front housing cover in place and remove it.

- Disconnect all wires from the pump and loosen the clamps.

- We take out the pump, disconnect the volute and inspect the impeller for debris and damage. The pump winding can be checked with a multimeter.

- We replace the faulty pump with a new original one from AEG, and assemble the machine in the reverse order.

The situation is much more complicated in the case of failure of the control board. Its malfunction can manifest itself in various symptoms, which may be associated with a malfunction of other units. That's why The first difficulty when working with an electronic module is diagnosing its malfunction. The second difficulty is how to determine whether the module can be completely replaced or repaired. It is best to entrust such work to a professional who will test the module using special equipment.

Let's celebrate! Replacing a faulty module can be quite expensive, about 40% of the cost of a new machine. Therefore, sometimes it is even wiser to think about buying a new washing machine.

In conclusion, we note that most common faults on machines of different brands are similar, and the elimination of such faults is carried out using similar algorithms. Repair of AEG washing machines that have been in use for more than 10 years may be required due to normal wear and tear of the machine components. But this does not mean that in all cases you can carry out repairs yourself; in some cases you will have to trust professionals, even if you really don’t want to overpay.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment