Malfunctions of Siemens washing machines

The European assembly of Siemens washing machines speaks for itself - machines rarely break down. The equipment undergoes strict testing, so the likelihood of manufacturing defects is reduced to zero. A malfunction of a Siemens washing machine can be caused by external factors beyond the control of the manufacturer. We are talking about power surges, too hard water, careless use. Let's figure out what kind of damage equipment owners most often encounter.

The European assembly of Siemens washing machines speaks for itself - machines rarely break down. The equipment undergoes strict testing, so the likelihood of manufacturing defects is reduced to zero. A malfunction of a Siemens washing machine can be caused by external factors beyond the control of the manufacturer. We are talking about power surges, too hard water, careless use. Let's figure out what kind of damage equipment owners most often encounter.

The most common breakdowns

Almost any element in a machine can break down. However, some faults are more typical for models of a certain brand. If we talk about Siemens washing machines, they are more typical:

- no heating;

- spontaneous freezing. Typically, in this case, the self-diagnosis system constantly displays error codes, so the machine cannot operate;

- malfunction of the hatch locking device;

- drain problem.

Problems with the main control board are slightly less common, and the software malfunctions. To minimize the risk of a Siemens washing machine breaking down, you need to handle the equipment carefully and follow all the requirements specified in the instructions. It is not always necessary to invite a specialist to repair a washing machine; most typical breakdowns can be dealt with on your own. Let's figure out what to do in each specific case.

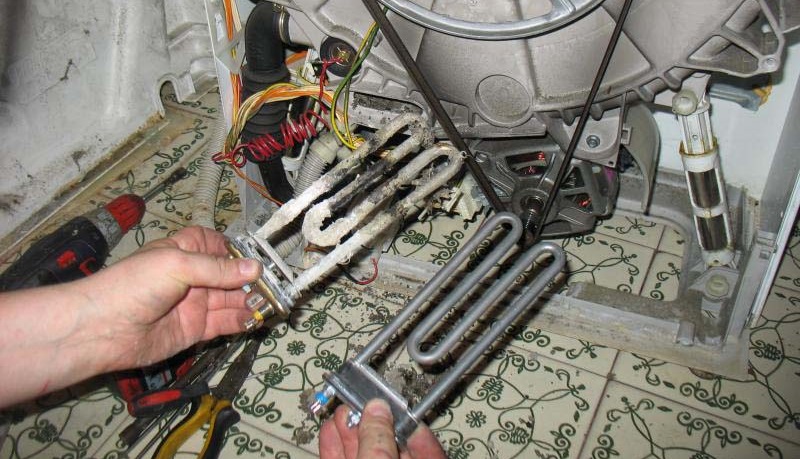

Heating element is always “under attack”

Siemens users most often encounter problems with water heating, this is especially noticeable when starting high-temperature cycles. Usually in such a situation the heating element is to blame. The heating elements that modern Siemens are equipped with have a relatively short service life - about 5 years. For comparison, heating elements of older models of this brand, released at the beginning of the 2000s, worked for 15-20 years, and are still functioning. The user can speed up the failure of the heating element with his own hands. Therefore, in order to maximize the “life” of the heater, you should:

- prevent the launch of several high-temperature washing programs in a row. Otherwise, the heating element will work “for wear”, which will provoke a faster breakdown;

- periodically clean the “home assistant”. Regular washing will help to remove scale from the heating element in a timely manner;

- Monitor the hardness of tap water. It is advisable to install a special softening filter at the entrance to the washing machine.

To diagnose the heater, you will have to remove the back wall of the housing. In the lower corner, under the tank, there is a heating element. Before checking the part, it is better to take a photograph of the wire connection diagram to the element so as not to make mistakes during reassembly. Next, you need to remove the wiring and test the heating element with a multimeter, applying the probes of the device to the heater terminals. If during diagnostics it is revealed that the element is faulty, you will have to dismantle the part and install a new one.

To remove the heating element with your own hands, loosen the central nut and push the pin inside. Next, “loose” the element a little and pull it out of the “socket”. A working heater is fixed in place with a screw and the wiring is connected to it. Finally, the body of the machine is assembled and a test wash is started.

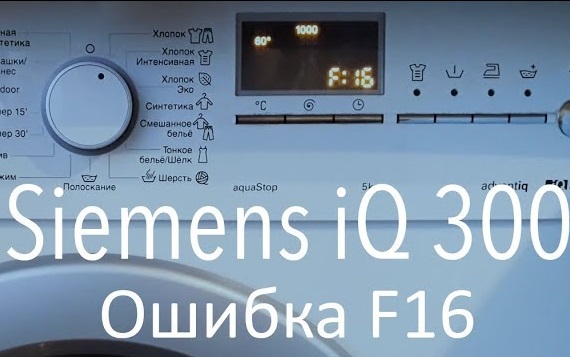

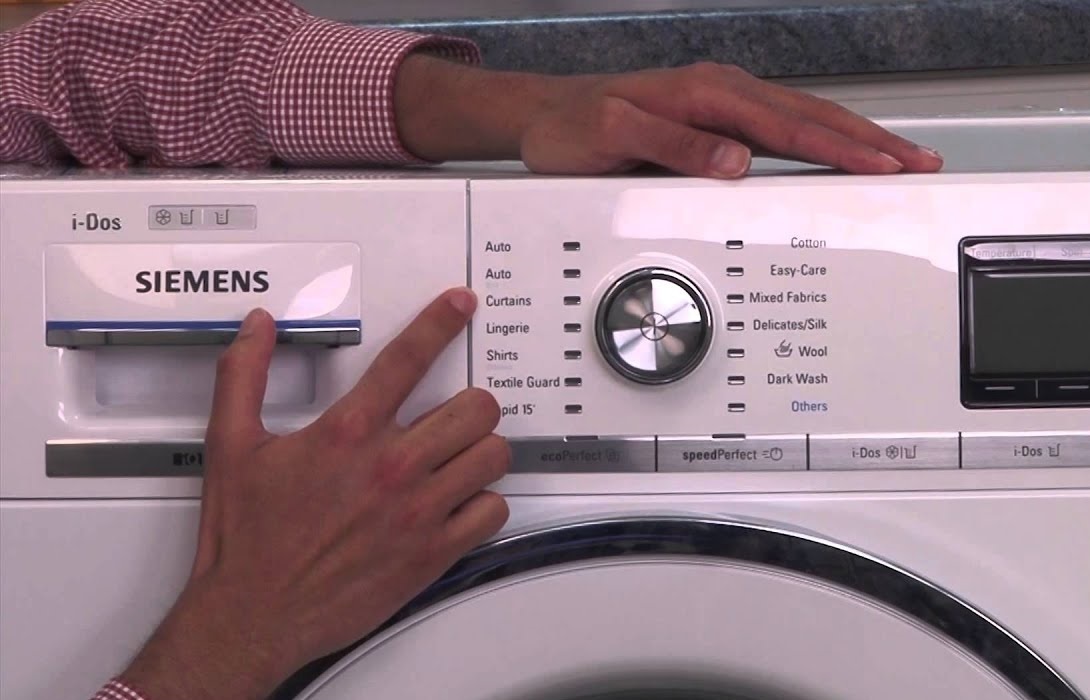

Errors are constantly displayed

Another problem with Siemens machines is the spontaneous activation of the diagnostic system. The machine literally freezes, issuing a fault code.After a reboot, the washer “comes to life”, forgetting about the error. Troubleshooting will involve starting the service mode. Automatic testing of the control module will help identify the real error that is causing this “freeze”. To activate test mode, you need to:

- turn the selector knob to the “Off” position. This will stop the wash that has started;

- disconnect the machine from the network;

- Press the “Start/Pause” and “Exit” buttons simultaneously. Hold them for 3-5 seconds;

- enable “home assistant”;

- turn the programmer one notch to the right;

- Press “Start” and “Exit” again until the error code is displayed on the screen.

The explanation of all fault codes is given in the instructions for the Siemens washing machine.

You should look at the user manual to understand what failure occurred in the system. The tactics for further repairs are determined depending on the breakdown.

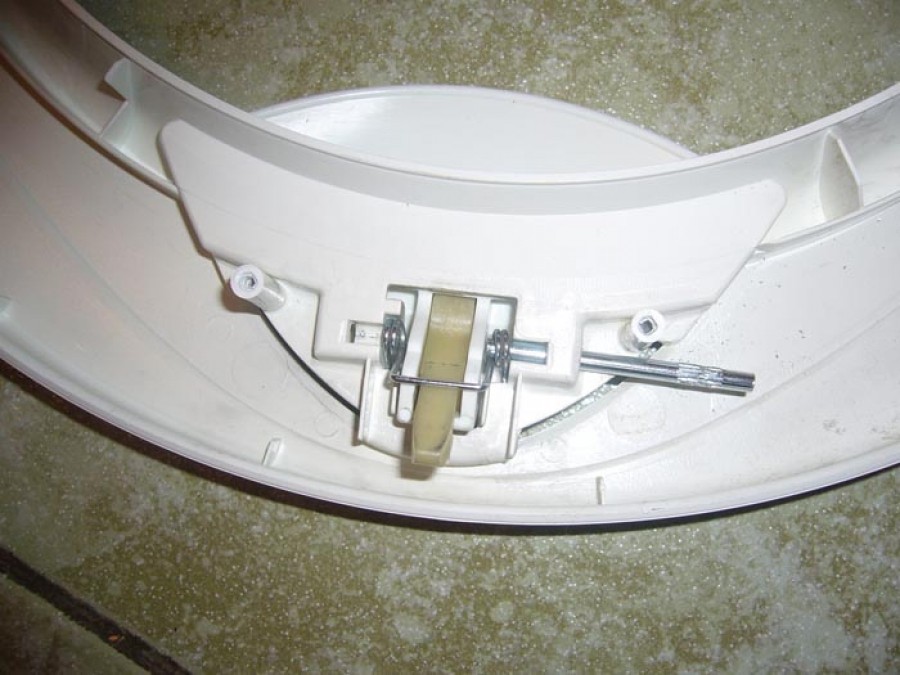

Door mechanism

Another weak point of Siemens washing machines is UBL. The door mechanism of German technology has plastic fasteners and not fully thought out latches. Therefore, problems with opening the hatch are often observed. Usually the door lock is affected. Burrs form on its lever and chips appear. This interferes with the coordinated operation of the mechanism. You can fix the problem yourself by doing the following:

- remove the door;

- take a file with a small notch;

- insert the tool into the hole and grind off the bumps on the lever;

- treat the surface of the lock with graphite lubricant;

- clean off excess graphite;

- put the hatch in place.

This way you can organize the work of UBL. If you can’t fix the blocker yourself, it’s better to invite a specialist.

Sewage pump

Problems with drainage are typical for Siemens.Usually the culprit of the problem is the pump. There is no point in repairing the pump; you need to immediately buy a new part. To dismantle the old and install a new element, you need:

- turn off the power to the washing machine;

- Unscrew the garbage filter, draining the remaining water from the system;

- lay the machine on its left side;

- disconnect the pipes and wiring from the pump;

- pull out the pump;

- install a new pump, fixing it in the housing.

Next, all that remains is to connect the removed pipes and wires to the pump. Screw the garbage filter into place. To check the quality of the repair, be sure to run a test wash “idle”.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment