Haier washing machine won't turn on

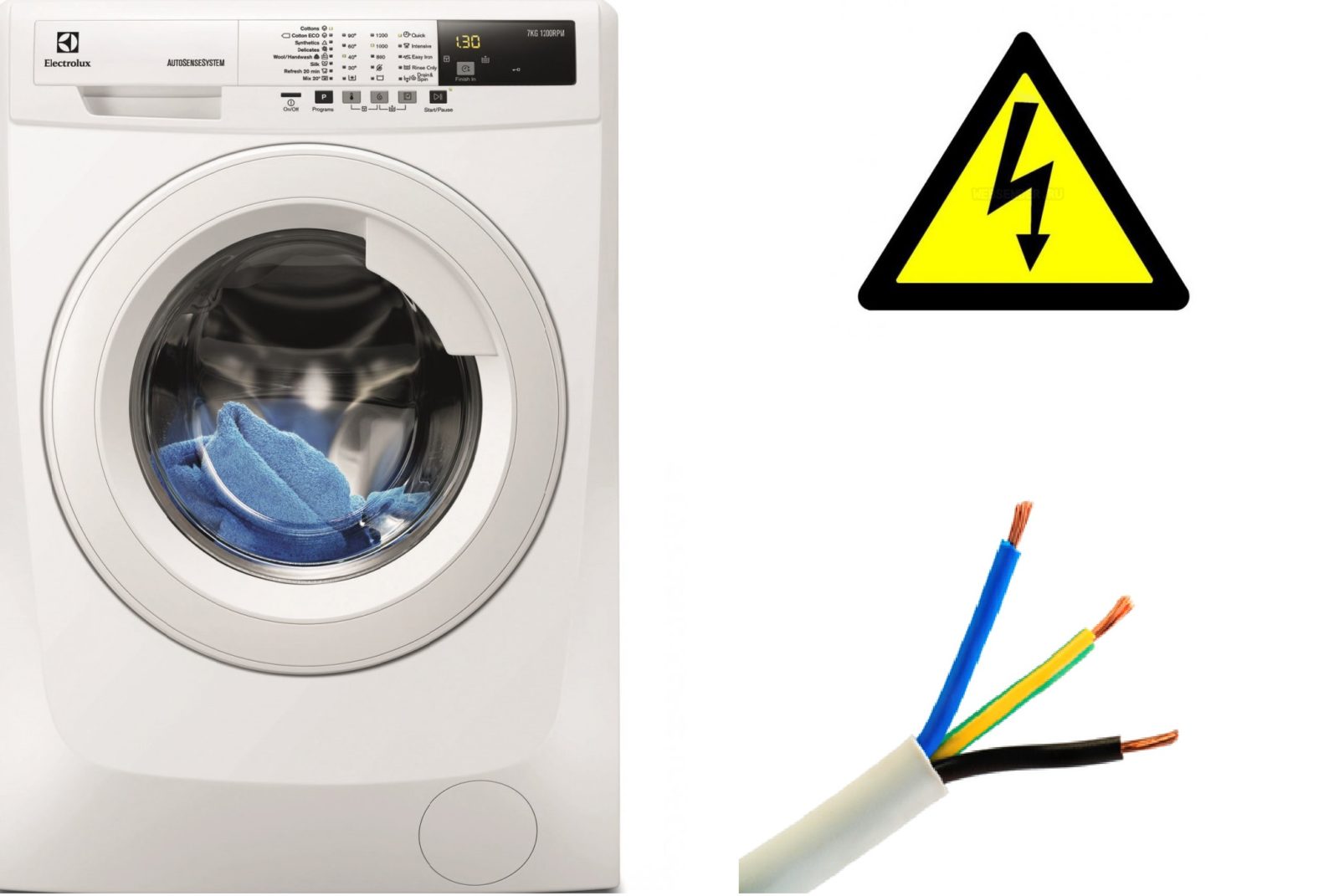

Sometimes the user, including the washing machine, may find that it does not respond to key presses. The first thing you need to check is whether the power cord is plugged into the socket and whether the electricity supply to the apartment is turned off. If everything is fine with this, then there is some kind of problem.

Sometimes the user, including the washing machine, may find that it does not respond to key presses. The first thing you need to check is whether the power cord is plugged into the socket and whether the electricity supply to the apartment is turned off. If everything is fine with this, then there is some kind of problem.

Why won't my Haier washing machine turn on? How to diagnose equipment? Is it possible to repair the device yourself at home? Let's look into the nuances.

List of possible problems

It’s very easy to understand that the washing machine won’t turn on. The control panel does not blink with lights, and pressing the keys on the dashboard does not produce results - the machine continues to be “silent”. All this indicates that the machine is cut off from power. The reasons for this may be different:

- shutdown of centralized electricity;

- network key stuck on the control panel;

- breakdown of the socket that powers the automatic machine;

- defective power cord or plug;

- failure of the noise filter;

- rupture of the supply wiring inside the automatic machine;

- Main control module malfunction.

To identify a malfunction, you will have to diagnose external electrical communications and check the automatic machine itself.

Diagnostics is carried out from simple to more complex. Check to see if the power supply is cut off. Next, check the power cord, the socket itself, and the wire plug. Let's take a closer look at what to do in this situation.

Main wire, socket or surge protector

The first thing you need to do is flip the switch. Perhaps everything is fine with the machine, and its reluctance to work is caused by a banal blackout.The next step is to check the electrical panel. Sometimes, when there is too much load on the network, the line cannot withstand it and the residual current device trips. In this case, you need to “throw off” the extra consumers and restart the system.

Next, inspect the outlet from which the washing machine is “powered”. Usually you can notice the problem with the naked eye:

- there are burns and dark spots on the socket body;

- there is a burning smell;

- there is smoke coming from the socket;

- The plastic housing of the socket is melted.

If there are no external defects, check the outlet by plugging in any working electrical appliance (for example, a hair dryer). If the device “buzzes”, it means the point is working. When there is also no contact, the reason is in the socket.

You can change the output yourself or by inviting an electrician. It is better to provide a separate outlet for the washing machine with a high level of moisture protection.

Having finished with external communications, it is worth paying attention to the automatic machine itself. First, take care of its power cord and check it for defects. Sometimes you may notice signs of fire on the cord or plug.

If the cord appears intact, test it with a multimeter. Having determined that the power cord is faulty, replace the element. Repair in this case will be impossible - covering defects with electrical tape is unsafe.

Next, you need to check the noise filter. FPS protects the washing machine from power surges. One sharp current surge can cause the device to burn out - because of this, the supply of electricity to the main components of the SMA will become impossible.

The interference filter is checked with a multimeter. You need to do the following:

- turn off the power to the automatic machine;

- turn off the valve responsible for supplying water to the washing machine;

- remove the top panel of the MCA (to do this, you need to unscrew the 2 bolts securing the cover);

- find the place where the power cord is connected to the washing machine body;

- find an interference suppression filter near the cord (this is a small “box” with rounded edges);

- disconnect all wiring connected to it from the interference filter;

- take the FPS out of the automatic machine.

When you have the filter in your hands, inspect it. There should be no traces of burns or melted contacts on it. If there are no external defects, arm yourself with a multimeter. Switch the tester to buzzer mode and ring the FPS.

If the multimeter screen displays 0 or 1, then the noise filter is faulty. The part cannot be repaired; you will have to buy a new device. The FPS is placed in its original place, all previously disconnected wires are connected to it.

Network key on the control panel

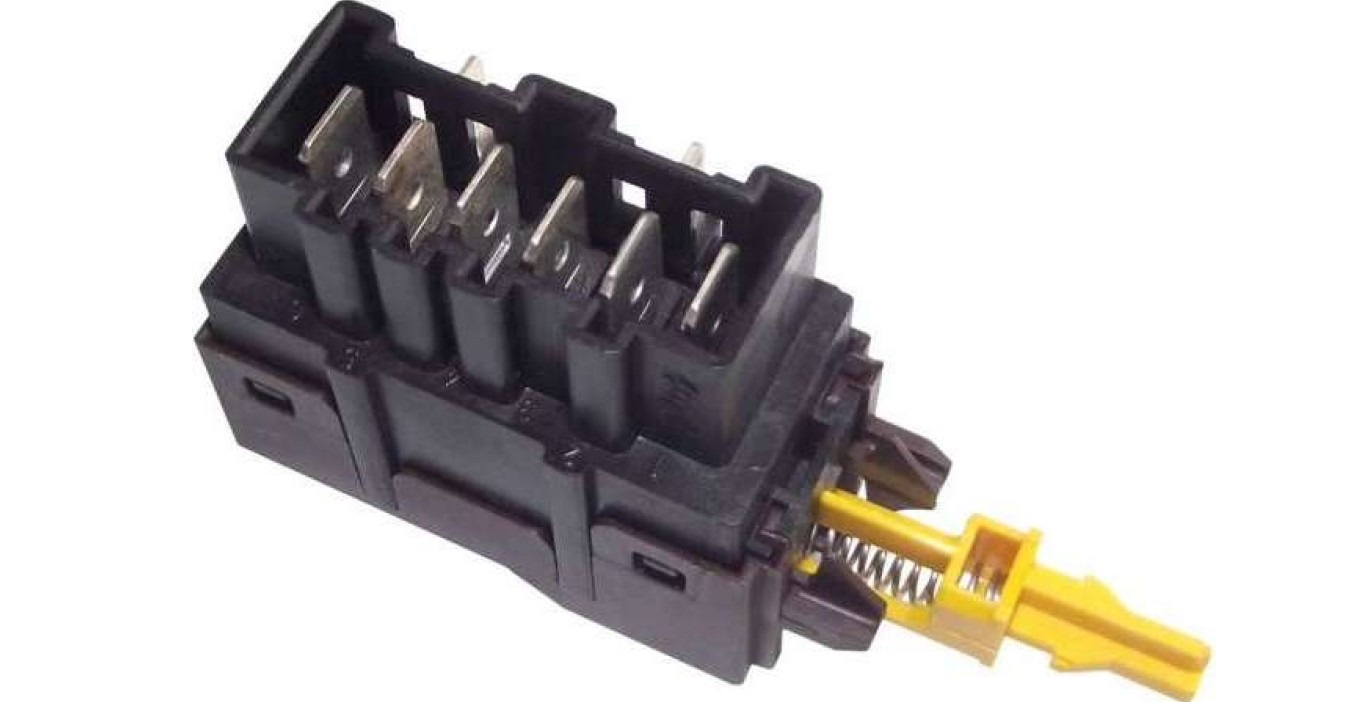

On older models of Haier washing machines, the power button is often stuck. And this could be the reason why the machine does not turn on. A faulty key prevents the supply of electricity to the control board, so the washing machine does not start.

Sticking keys are often observed on typewriters that are in the bathroom. Water gets under the button and causes oxidation of the contacts. The current exchange is disrupted, the washing machine stops turning on.

The serviceability of the network button is checked as follows:

- turn off the power to the washing machine;

- remove the top cover of the automatic machine;

- look inside the case - find the network key on the back of the device;

- disconnect the wires connected to it from the button;

- use a screwdriver to pry up the plastic, release the latches and pull the key out.

Next, the button needs to be tested with a multimeter. First it is checked for breakdown, then for resistance. If the device detects a deviation from the standard values, you will have to buy and install a new key. Sometimes cleaning the contacts can help, but it is recommended not to risk it and replace the element immediately.

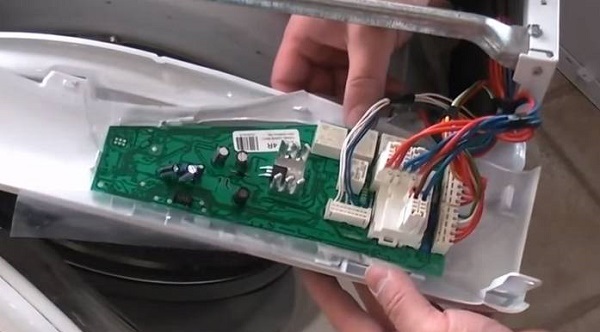

Problem with the semiconductor element of the control module

If everything is in order with the socket, power cord, noise filter and key, there is most likely a malfunction of the main unit. This problem is considered one of the most difficult and costly to repair. Semiconductor elements on the control board are sensitive to power surges, and during sudden changes they burn out. The “chain” is interrupted and the machine does not turn on.

It is very difficult to identify a damaged semiconductor - there can be dozens or even hundreds of them on the board.

Sometimes the damaged area can still be identified with the naked eye - to do this you need to inspect the control board. Follow these steps:

- turn off the power to the machine;

- remove the powder receptacle from the SMA;

- remove the “top” of the housing;

- Unscrew the screws holding the SMA dashboard;

- “halve the tidy”, helping yourself with a flat screwdriver;

- pull out the control board.

What should you look for on the board? Any defects - black spots, oxidized areas, melted wiring. If visually everything is in order, you will have to contact the service center specialists to carry out diagnostics.

You should not test and repair the control module yourself without sufficient knowledge and experience. This can damage the part even more. Only a competent technician can identify and solve the problem.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment