Whirlpool washing machine does not spin clothes

There are several reasons why the Whirlpool washing machine does not spin out clean and rinsed items. These include a malfunction in the drain system, interruptions in the operation of the motor, and a burnt-out level sensor with a broken control module. You can only assess the extent of the necessary repairs by calling a specialist or conducting diagnostics yourself. For those who chose the second option, here are our instructions.

There are several reasons why the Whirlpool washing machine does not spin out clean and rinsed items. These include a malfunction in the drain system, interruptions in the operation of the motor, and a burnt-out level sensor with a broken control module. You can only assess the extent of the necessary repairs by calling a specialist or conducting diagnostics yourself. For those who chose the second option, here are our instructions.

What could have broken?

You can suspect the absence of a full-fledged mode by the obvious signals given by a faulty machine. The most “talking” will be the water remaining in the drum and absolutely wet laundry, even after the end of the “Spin” mode. Warning “symptoms” include unusually noisy or too slow drainage, interruptions in signal transmission when changing a program, and the humming of the washing machine when there is no speed or vibration. If at least one of the proposed options occurs, we begin to understand the problem.

There are several sources of spin not functioning at full strength, and all of them are of a technical nature. An example is a problem with the drainage system. When the washer stops after washing and rinsing, you need to check the drain. Most likely, the water simply cannot escape due to a blockage in the hose, insufficient pump power, or some contacts coming off. This is not the only possible problem.

- Faulty level sensor. It is responsible for supplying information to the control board about the water level in the tank. If the machine does not recognize the signal that the drum is full, the system will not drain it.

- Broken module.It consists of triacs that control the operation of certain parts and processes in the system. As soon as it burns out, the board stops controlling and switching modes.

- Problems with the electric motor. There is a noticeable reduction in power and rpm. The reason is difficult engine operation due to burnt wiring, broken contacts or worn electric brushes. If the situation is not corrected soon, the machine will stop turning on.

- Inoperative tachogenerator. A sensor that controls the number of engine revolutions. If there is a malfunction in its operation, the drum slows down during the cycle and insufficient rotation at its end.

Each type of breakdown is serious and requires immediate repair. However, before you begin testing and diagnosing, it is important to confirm the presence of the problem and narrow down the problem area. We'll tell you what we do first.

Priority actions

You cannot immediately disassemble the machine and repair the engine with a pump. First, it is recommended to carry out a few simple tests and confirm that the spin cycle of the washer is not working. We act in an orderly manner.

- We look at the control panel and fix the enabled mode. If a program without spinning, soaking or delicate washing is selected, then the signal was false. We switch to express or spin, adjust the maximum number of revolutions and start the cycle.

- Let's look into the drum. Whirlpool machines with a vertical loading type automatically slow down the rotation rate due to overload or imbalance. This protects the washing machine from overheating and excessive spinning, which is easy to bypass. It is enough to take out some of the things or evenly distribute the stray “lump”.

Important! Most modern models have the “Imbalance Protection” function, so this problem can only appear on older machines.

When the spin button is on, there is no imbalance, but the machine still does not spin, diagnostics are inevitable. In this case, disconnect the machine from the power supply, shut off the water supply and empty the tank. We provide free access to the machine and begin the inspection.

Possibly a problem with the pump

Most often, the Whirlpool machine stops an unfinished cycle and threatens with a tank full of water due to problems in the drainage system. Firstly, the liquid simply cannot leave the drum and start the next washing stage. Secondly, even with intense rotation, clothes do not dry out while in water, so we start checking with the pump:

- we find the drain hatch, which is located in the lower right corner of the body;

- release the latches and open;

- place the dishes under the hole;

- take out the filter;

- we check the impeller, for which we start spinning or draining (then we observe the part, if it is spinning, everything is in order, if there is no rotation, we disassemble the pump);

- Next, we inspect the drain pipe: turn the machine on its side, release the clamps through the bottom and check for debris in the hose;

- disconnect the pump from the connected conductors and fastenings;

- We clean all elements from accumulated debris and foreign objects.

It is the blockages that are the main source of the problem with a faulty drain system. Therefore, it is important to regularly clean hoses and tubes and test them for flow. After completing all the steps and reassembling, start the spin cycle and watch the drain. If the situation with stagnation repeats, you will have to completely change the pump.

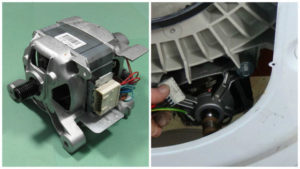

Let's check the motor and Hall sensor

Next in line for testing are the electric motor and tachogenerator. If there are malfunctions in their operation, the drum stops or rotates slowly, which makes high-quality spinning impossible. So, let's inspect the motor according to the following scheme:

- unscrew the back cover of the SM case;

- carefully remove the drive belt by pulling it towards you while rotating the pulley;

- we take out the engine by unscrewing the retaining screws or bolts;

- we take out the brushes on both sides of the motor and measure the length of the carbon tip (more than 1.5 cm is normal, less - needs to be changed).

- we look closely at the wires, the insulation of which should not have fractures, burnt areas, or cracks;

- we test the winding for short circuits.

Attention! If the multimeter shows a short circuit in the winding, you should not replace it yourself - a complete replacement of the motor is necessary.

A Hall sensor is also connected to the engine, which monitors the quality of motor operation and makes it orderly. If it breaks, the drum does not spin up to the required speed and does not wring out the clothes. It cannot be repaired, only a complete replacement is possible. To do this, we take out the electric motor according to the previously mentioned diagram, find the tachometer coil on its body, dismantle it and install a new one.

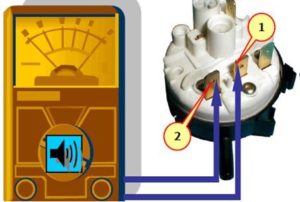

Is the pressure switch working?

When the Whirlpool washing machine stops spinning, and the Hall sensor and pump are normal, you need to pay attention to the pressure switch. Its task is to report to the control board the level of water in the tank, and based on the data received, the system sends a signal to drain. A faulty level gauge is “silent” about stagnation, the machine does not empty and does not open. The problem is solved using a fairly simple scheme.

- We drain the water through a garbage filter.

- We wait for the lock to automatically unlock and open the door.

- We find the pressure switch, which is located under the top cover of the machine.

- We prepare a tube with a diameter identical to the sensor fitting.

- Unclench the retaining clamps and remove the hose.

- We install the tube on the level gauge and blow it in (if you hear 1-3 clicks, it means the contacts have worked, otherwise the sensor is faulty).

- Inspect the surface of the part for scratches and cracks.

- We clean the blockages under a strong stream of water.

- We test the element with a multimeter in resistance mode, and when the values on the display change, we make sure that everything is fine.

If there is no click, there is damage, unwashable blockages, or the same number remains on the multimeter screen, the pressure switch must be replaced. It is better to contact the service department with such a problem. For self-repair, it is enough to purchase a similar device from a specialized store and install it in its original place.

Let's check the electronic stuffing

When the elements of the washing machine individually function normally, but there is still no spin, there is a high probability that the electronics are damaged. In this situation, “glitches” occur not only with drying things, but also with other stages of washing. For example, the following situations indicate problems with the “brains” of the machine:

When the elements of the washing machine individually function normally, but there is still no spin, there is a high probability that the electronics are damaged. In this situation, “glitches” occur not only with drying things, but also with other stages of washing. For example, the following situations indicate problems with the “brains” of the machine:

- the drum does not stop and rotation stops only after the cycle is forced to complete;

- The machine does not wash, it only rinses and spins;

- The washer does not rinse, but only performs an initial wash.

Important! Only a professional can carry out accurate diagnostics of the control module.

You can only visually inspect the board yourself.To do this, disconnect the machine from the power supply, remove the top cover and take out the powder receptacle. Next, frees the dashboard from screws and plastic clips. Afterwards, all that remains is to disconnect the wires and inspect the part for external damage.

Don't forget about prevention

In order not to say goodbye to semi-dry things and not to notice residual water in the drum, you must follow the rules for operating the Whirlpool machine. This way you can prevent breakdowns and not rack your brains over the source of the problem. We are talking about the simplest recommendations when using the machine.

- Keep foreign objects and debris out of the drum by carefully checking all pockets and folds of clothing.

- Install household appliances in rooms with low humidity, allocate a separate outlet and do not use extension cords.

- Turn off the device from the network if the washing machine is not used for a long time.

- Wash items with metal decor and hard inserts only in special bags.

- Do not exceed maximum loading weight.

- Use Voltage regulatorto protect electronics from surges and sudden shutdowns.

- Use only suitable powders of excellent quality.

- Clean the filters, powder receptacle and drain hoses regularly (every two months).

- Run the “empty” mode after the last cycle to clean the drum.

- Dry the internal surfaces of the machine, leaving the door open after use.

Without spinning, washing turns into a headache, so at the first sign of a decrease in speed or problems with drainage, you need to sound the alarm. It is possible to independently assess the extent and source of the breakdown if you follow the instructions above and take your time.Do you feel like you can't cope? Contact customer service for professional assistance.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment