Electrolux washing machine drum does not rotate

Each manufacturer of household appliances has its own typical faults. For example, the washing machine drum of Electrolux brand appliances often does not spin - it suddenly slows down or jams. In the latter case, it is not even possible to turn the cylinder by hand - the container “stands up” tightly and does not allow you to continue washing. There is no way around this without diagnostics and repairs. It is necessary to identify the “sore spot” and begin repairs.

Each manufacturer of household appliances has its own typical faults. For example, the washing machine drum of Electrolux brand appliances often does not spin - it suddenly slows down or jams. In the latter case, it is not even possible to turn the cylinder by hand - the container “stands up” tightly and does not allow you to continue washing. There is no way around this without diagnostics and repairs. It is necessary to identify the “sore spot” and begin repairs.

Where did the breakdown come from?

It is impossible to immediately say why the drum suddenly stopped. There are many possible causes of malfunction, and the final list of breakdowns depends on the brand and model of Electrolux, as well as the components used, including the country of assembly. But, as a rule, the user encounters the following breakdowns that slow down the machine:

- an object is stuck between the tank and the drum, jamming the mechanism;

- there are problems with the drive, belt or pulley;

- the electric motor coil has failed;

- carbon electric brushes are worn out;

- the lamellas on the motor have peeled off;

- the semiconductor elements on the control board are damaged, or the module itself is broken.

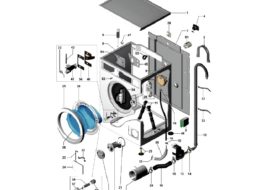

This is not a complete list. It is worth understanding that even a simple Electrolux is equipped with many interconnected components, sensors and microcircuits. Even the slightest failure in one part can lead to a complete stop of the washing machine. Diagnosis is also complicated by the fact that the symptoms of some breakdowns are identical to completely different faults. As an amateur DIYer, it is not easy to accurately localize the problem. It is better not to rush to conclusions, but to contact a service center.But you can deal with the braking drum on an Electrolux washing machine on your own. The main thing is not to delay diagnosis.

On an Electrolux machine, the drum does not rotate due to jamming, problems with the drive, breakdown of the motor or control board.

It is important to clarify that the list of reasons will increase if the drum, although unstable, rotates. In this case, the range of possible malfunctions expands. This article discusses the situation with a complete stop of the cylinder.

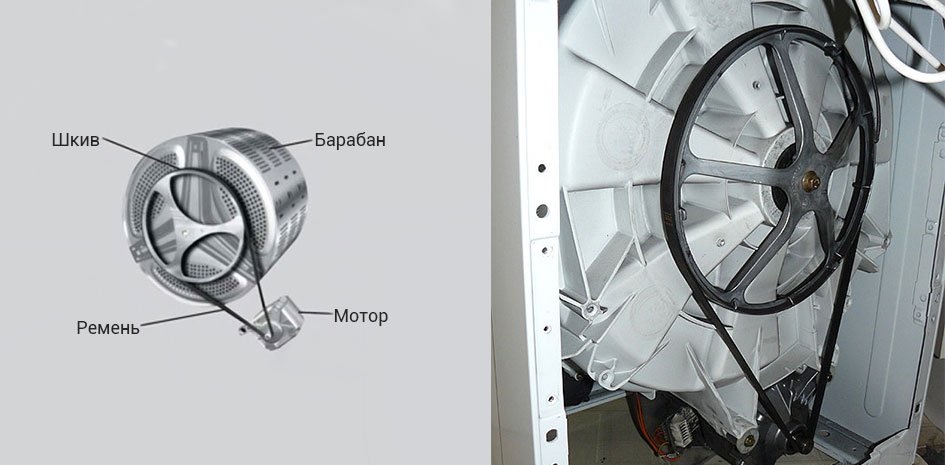

Drive mechanism elements are broken

If the drum on the washing machine does not rotate, then the first thing you need to check is the drive belt. It has probably torn or fallen off, which is why the impulse from the running engine is not transmitted to the drum shaft. The situation itself is not scary: just remove the back panel and return the elastic band to its place.

Repair becomes more difficult if the belt falls off constantly, more than three times every six months. In this case, you need to change the very stretched rubber band or check the drum pulley for integrity. We proceed like this:

- disconnect the machine from communications;

- we move the equipment away from the wall, opening access to the “back”;

- unscrew the back panel or service hatch (depending on the Electrolux brand);

- We inspect the large and small pulleys, check the belt.

If the rubber band is in place, then the failure is not in the drive. A belt that has fallen off will indicate problems with the “wheel” - you need to inspect it for damage and deformation. When there are no visible defects, you can return the rubber to its place and start the washer again. If chips or cracks occur, replace the part with a serviceable one.

If the drive belt breaks once, it is enough to return it to its place; if it breaks regularly, it is necessary to check the integrity of the pulley and rubber band.

The next step is to inspect the small pulley located on the motor shaft. A deformed wheel needs urgent replacement.

To replace a large pulley with your own hands, you must follow the following instructions:

- fix the wheel in a stationary position by inserting a screw or a wooden block;

- treat the central bolt with WD-40 and wait 30-40 minutes;

- Unscrew the bolt using a ratchet of a suitable size (do not use excessive force, as you can break the thread and damage the screw);

- remove the wheel;

- place a new pulley on the rod and secure it with a bolt.

Then all that remains is to tighten the drive belt. First, the elastic band is put on the small pulley, and then on the large one. Ideally, it is recommended to change the rim itself to prevent a recurrence of failure.

Foreign object is to blame

Getting a foreign object inside the machine can lead to more than just a drum wedge. Paper clips, keys, coins, buttons, and hairpins can damage the walls of a metal cylinder or plastic tank, clog the drain, or jam the pump impeller. Therefore, it is recommended to check the pockets of the laundry loaded into the washing machine - there should be no forgotten items in them!

Getting a foreign object inside the machine can lead to more than just a drum wedge. Paper clips, keys, coins, buttons, and hairpins can damage the walls of a metal cylinder or plastic tank, clog the drain, or jam the pump impeller. Therefore, it is recommended to check the pockets of the laundry loaded into the washing machine - there should be no forgotten items in them!

More often than not, objects accidentally falling into the tank lead to jamming of the drum. In this case, the machine suddenly stops with a clang, signaling an error. Trying to unscrew the cylinder by hand or restart the washing program is prohibited - this could make the situation worse!

It is prohibited to operate a washing machine with a jammed drum - you can aggravate the situation and pierce the cylinder or tank!

There is only one way out - remove the foreign body from the tank. This can be done through a special niche in which the heating element is placed.If the heater on the Electrolux is located at the back, then it is better to operate through it. The instructions are as follows:

- disconnect the washing machine from the network;

- drain the water using emergency drain (if the machine stops in the middle of the cycle);

- remove the back panel from the case;

- find the heating element located under the tank;

- disconnect the connected wires from the heater;

- loosen the retaining nut and, swinging, pull the heating element out;

- Insert a wire hook or hand into the vacated hole and remove the stuck object.

If the heating element on Electrolux is located at the front, then it is better to operate through the drain pipe. Otherwise, you will have to remove the front panel of the case, which is much more difficult and time-consuming. Having selected the drain, place the washer on its left side, look through the bottom, free the drainage hole by removing the snail, and use your hand to catch the stuck object.

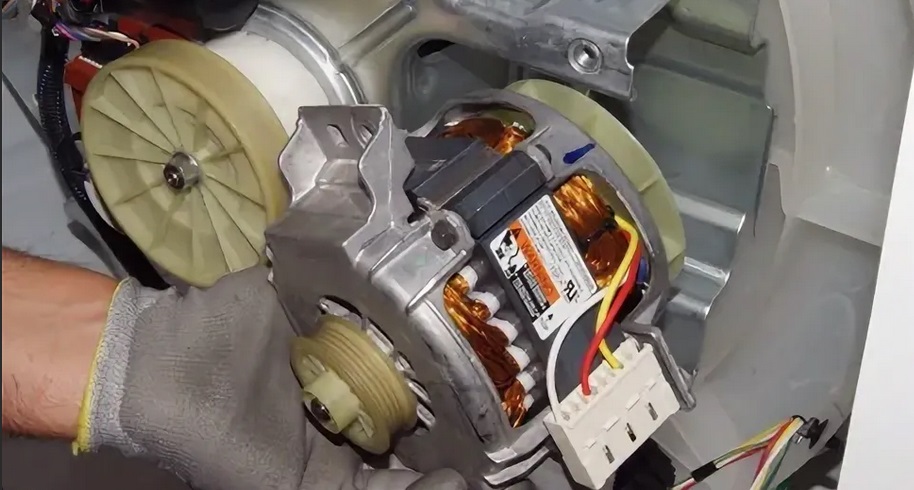

Motor faulty

The drum will not rotate even if there are problems with the electric motor. It's simple: the motor does not reach the set speed, the drive stands still, and the drum shaft does not spin up. Inverter engines on Electrolux stop extremely rarely, while collector engines, on the contrary, slow down quite often.

As a rule, commutator motors break down due to:

- worn out electric brushes;

- closed winding;

- peeled lamellas.

Diagnosing and repairing an engine is not an easy task. It is necessary to remove the motor from the washing machine body and test it for functionality with a multimeter. It is not easier after determining the cause of the malfunction. If you can cope with replacing brushes on your own at home, then sharpening the lamellas and restoring the integrity of the winding should only be done by professionals using special equipment.

Electronic filling

The most serious failure that leads to the drum stopping is a failure in the control board. It is strongly not recommended to diagnose and correct this problem yourself. Only a professional should dismantle, inspect and “ring” the electronic module. Firstly, experience and special equipment are required. Secondly, you will have to check each semiconductor, contact and microcircuit one by one. Thirdly, the cost of an error is too high - a careless movement will aggravate the situation to the point of death. The cost of a new unit is often equal to the price of a new Electrolux.

Diagnosis and repair of the control board should only be performed by professionals!

If the control board breaks down, the machine inevitably stops working. In this case, it is not necessarily the triac responsible for the engine and tachogenerator or the corresponding track that fails - probably a completely different microcircuit is faulty. The fact is that even one burnt semiconductor interrupts the well-thought-out electronic control chain. In this case, the module cannot receive information about the readiness of the node, transmit the command further, or control the process. For safety reasons, the system is shut down immediately.

If the control board breaks down, the machine inevitably stops working. In this case, it is not necessarily the triac responsible for the engine and tachogenerator or the corresponding track that fails - probably a completely different microcircuit is faulty. The fact is that even one burnt semiconductor interrupts the well-thought-out electronic control chain. In this case, the module cannot receive information about the readiness of the node, transmit the command further, or control the process. For safety reasons, the system is shut down immediately.

If during checking the drive, drum or motor a fault was not found, then it is better to stop the diagnosis and contact a service center. Doing electronics yourself is too risky - it’s safer and cheaper to call a specialist.

Interesting:

Reader comments

- Share your opinion - leave a comment

Add a comment